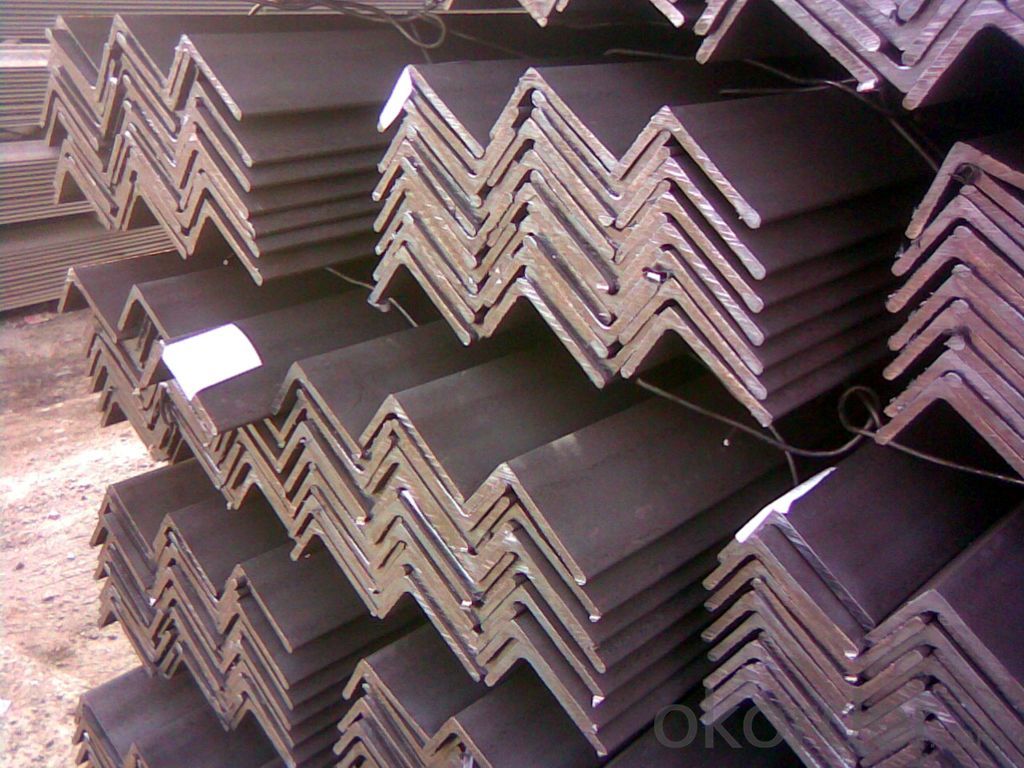

S235JR Equal steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering S235JR Equal steel angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

S235JR Equal steel angle are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel angle are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

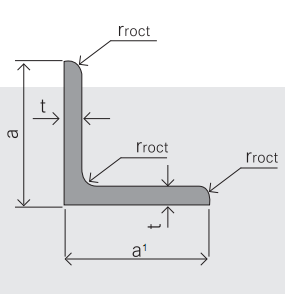

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400;

SS540.

4.Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5.aterial details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of GB Equal Structural Angle

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of GB Equal Structural Angle

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What are the factors to consider when choosing the appropriate steel angle size?

- When it comes to selecting the right size for a steel angle, there are several factors that need to be taken into account. To begin with, it is crucial to consider the load-bearing capacity. Determining the maximum weight or load that the steel angle needs to support is of utmost importance. This will help in choosing a size that can withstand the required load without any deformation or failure. In addition, one should also consider the structural stability and safety. The steel angle must possess the necessary strength and rigidity to maintain the structural integrity of the application. It is essential to ensure that the chosen size can withstand any potential structural failures or instabilities caused by external forces or loads. Another factor that needs to be considered is the dimensions and shape of the application where the steel angle will be used. The size of the steel angle should be compatible with the available space and design requirements. It is crucial to select a size that can easily fit into the overall structure and provide the desired functionality. Moreover, it is important to evaluate the material properties of the steel angle. Different grades and types of steel have varying mechanical properties, such as yield strength, tensile strength, and corrosion resistance. By taking into account the specific requirements of the application and the environmental conditions, one can choose the appropriate steel grade and size to ensure durability and longevity. Lastly, the cost and availability of the steel angle should also be considered. It is important to select a size that is readily available in the market and falls within the budget constraints. Comparing prices and availability from different suppliers can help in making an informed decision without compromising on quality and performance. In conclusion, factors such as load-bearing capacity, structural stability, dimensions and shape, material properties, and cost/availability should all be carefully considered when selecting the appropriate size for a steel angle. By evaluating these factors, one can make a well-informed decision that meets the specific requirements of the application.

- Q: Can steel angles be painted over?

- Yes, steel angles can be painted over. Prior to painting, it is important to clean and prepare the surface by removing any rust, dirt, or grease. Applying a primer will help improve adhesion and longevity of the paint. Once the primer is dry, a suitable paint can be applied to achieve the desired finish and protect the steel angles from corrosion.

- Q: Can steel angles be used in solar panel mounting systems?

- Yes, steel angles can be used in solar panel mounting systems. Steel angles are commonly used due to their strength and durability, providing a stable and secure base for solar panels. They can be easily adjusted and customized to fit various installation requirements, making them a popular choice in solar panel mounting systems.

- Q: What are the different methods of fire protection for steel angles?

- Depending on specific requirements and regulations, there exist several methods for fire protection of steel angles. Some commonly used methods include: 1. Passive Fire Protection: Fire-resistant materials, such as fire-resistant coatings, fireproofing sprays, or intumescent paints, are directly applied to the steel angles. These coatings serve to delay fire spread and provide insulation, safeguarding the steel angles from high temperatures during a fire. 2. Encasement: Steel angles can be enclosed in fire-resistant materials like concrete or gypsum board. This creates a barrier that prevents the fire from reaching temperatures that could result in structural failure. 3. Fireproofing Systems: Fire-resistant boards or panels are affixed to the steel angles, forming fireproofing systems. These systems offer insulation and protection against fire, slowing down the heating process and maintaining the structural integrity of the steel angles for an extended period. 4. Sprinkler Systems: The installation of sprinkler systems is also an effective fire protection measure for steel angles. These systems are designed to detect and suppress fires by releasing water or fire-suppressing agents upon activation. By swiftly extinguishing the fire, sprinklers can prevent the steel angles from reaching critical temperatures. 5. Fire-resistant barriers: Fire-resistant walls or curtains can be employed as barriers to separate steel angles from potential fire sources. These barriers aid in containing the fire and preventing its spread to the steel angles, providing an additional layer of protection. To determine the most suitable method of fire protection for steel angles in a specific setting, it is crucial to consult fire protection experts, engineers, and local building codes. Factors such as building type, fire safety requirements, and the level of fire risk involved may influence the choice of method.

- Q: Are steel angles suitable for balcony construction?

- Yes, steel angles are suitable for balcony construction. Steel angles are commonly used in construction due to their strength and durability. They provide excellent support and stability, making them ideal for balcony construction. Steel angles can withstand heavy loads and are resistant to weathering and corrosion, making them a reliable choice for outdoor structures like balconies. Additionally, steel angles can be easily customized and fabricated to meet specific design requirements, allowing for flexibility in balcony construction. Overall, steel angles are a popular and suitable choice for balcony construction due to their strength, durability, and versatility.

- Q: Can steel angles be used for sign or billboard support structures?

- Steel angles can serve as support structures for signs or billboards. They are commonly utilized in construction due to their robustness and longevity. These angles offer exceptional support for a range of structures, including sign or billboard installations. They are adaptable and can be effortlessly customized and installed to meet the precise demands of the signage or billboard. With their ability to endure substantial loads and adverse weather conditions, steel angles are a perfect choice for supporting these structures. Moreover, they can be painted or coated to enhance their aesthetic appeal and shield them from corrosion, thus prolonging their lifespan.

- Q: Are steel angles suitable for historical restoration projects?

- Yes, steel angles can be suitable for historical restoration projects. They offer excellent strength and durability, which is useful for structural support and reinforcement. Additionally, steel angles can be easily fabricated to match the original design and can be finished to closely resemble the aesthetic of historical materials. However, careful consideration should be given to the specific project requirements and the preservation of historical integrity.

- Q: What is the minimum radius for a curved steel angle?

- The minimum radius for a curved steel angle depends on various factors, including the thickness and width of the steel angle, as well as the desired degree of curvature. In general, the minimum radius for a curved steel angle is determined by the limitations imposed by the material's ability to bend without causing permanent deformation or cracking. It is important to consult the manufacturer's guidelines or an engineer specializing in structural steel to determine the specific minimum radius for a given curved steel angle.

- Q: Can steel angles be used as reinforcement in concrete slabs?

- Concrete slabs can indeed benefit from the use of steel angles for reinforcement. These L-shaped structural steel components, commonly utilized in construction due to their durability and strength, can significantly enhance the load-bearing capacity of a concrete slab. Furthermore, they help prevent any potential cracks or structural failure. Specifically, steel angles provide added support and strength to the concrete, especially in areas where heavy loads or concentrated forces are anticipated. By incorporating steel angles as reinforcement, the concrete slab becomes more resistant to bending, tension, and shearing forces, resulting in a structurally sound slab that can withstand higher loads. It is crucial to ensure the proper design and placement of steel angles, following the guidelines and specifications provided by structural engineers, to guarantee the optimal reinforcement and performance of the concrete slab.

- Q: How do steel angles contribute to sustainable construction?

- Steel angles play a crucial role in sustainable construction in various ways. To begin with, steel possesses remarkable durability and longevity, resulting in structures built with steel angles having a longer lifespan compared to those constructed with alternative materials. As a result, the necessity for frequent repairs or replacements is reduced, thereby minimizing waste and lessening the overall environmental impact of construction. Furthermore, steel is an extremely recyclable material. When a structure reaches the end of its life cycle, steel angles can be effortlessly recycled and repurposed for other construction ventures. This diminishes the demand for new steel production, which consumes significant energy and can result in substantial carbon emissions. Moreover, steel angles offer architects and engineers design flexibility, enabling them to create more efficient and innovative structures. This can lead to optimized building designs that require less energy for heating, cooling, and maintenance, contributing to energy savings and a decrease in greenhouse gas emissions. Additionally, steel angles are lightweight yet remarkably sturdy, resulting in reduced material usage and transportation costs. Consequently, the overall carbon footprint associated with steel construction is lower compared to other materials. Furthermore, steel angles possess exceptional fire resistance properties, making them a safer choice for construction. This prolongs the lifespan of structures and diminishes the risk of damage or destruction during fires. As a result, the need for rebuilding or reconstructing is reduced, leading to less material waste and environmental impact. In conclusion, steel angles contribute to sustainable construction through their durability, recyclability, design flexibility, energy efficiency, lightweight nature, fire resistance, and overall reduced environmental impact. By incorporating steel angles into construction projects, we can create more sustainable and environmentally friendly structures that benefit both the present and future generations.

Send your message to us

S235JR Equal steel angle for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords