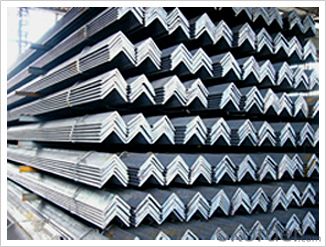

Angle steel, small angle, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse.

Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two.

Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 12.5cm for large angle steel, 12.5cm - 5cm for the medium angle, length of 5cm for smallangle.

Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series.

Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m.

Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125

Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc.

- Q: Can steel angles be used for transportation infrastructure projects?

- Yes, steel angles can be used for transportation infrastructure projects. Steel angles are commonly used in the construction of bridges, highways, and railway structures due to their strength, durability, and ability to withstand heavy loads. They provide necessary support and stability to various components of transportation infrastructure, making them an ideal choice for such projects.

- Q: How are steel angles cut to specific lengths?

- To achieve specific lengths, various cutting tools and techniques are employed for steel angles. Among these, a common approach involves the use of saws, such as band saws or circular saws with metal-cutting blades. By securely clamping or holding the angle in place, a precise and clean cut can be made as the saw blade is guided along the desired cutting line. Alternatively, an abrasive cutting wheel, also known as a cutoff wheel or grinding disc, can be utilized. This method is particularly suitable for thinner steel angles or situations requiring a more accurate cut. By securing the angle in a vise or similar holding device, the cutting wheel is cautiously guided along the marked cutting line, removing excess material. For larger and thicker steel angles, plasma cutters or oxy-fuel torches are viable options. Both methods involve elevating the steel's temperature to a point where it either melts or oxidizes, enabling a meticulous and precise cut. Plasma cutters utilize a focused jet of ionized gas, while oxy-fuel torches employ a combination of oxygen and a fuel gas, like acetylene or propane. In certain cases, more specialized techniques such as water jet cutting or laser cutting can be utilized to cut steel angles. Water jet cutting employs a high-pressure stream of water mixed with abrasive particles to erode the steel, while laser cutting relies on a concentrated laser beam to melt or vaporize the material along the intended cutting path. Regardless of the chosen method, it is crucial to firmly secure the angle in place and accurately guide the cutting tool along the marked cutting line. When cutting steel angles to specific lengths, it is important to prioritize safety by taking appropriate precautions like wearing protective eyewear and gloves.

- Q: Can steel angles be used in cold-formed steel construction?

- Certainly, cold-formed steel construction can incorporate steel angles. This construction method entails shaping thin gauge steel sheets into diverse profiles and forms, including angles. Within cold-formed steel construction, steel angles find widespread application in framing systems, support members, and bracing elements, offering structural robustness, stability, and effortless connection or welding with other cold-formed steel components. Moreover, steel angles can be tailored and manufactured to satisfy precise project demands and design specifications in cold-formed steel construction.

- Q: What is the fire resistance rating of steel angles?

- The fire resistance rating of steel angles varies depending on the specific dimensions and configuration of the angle, as well as the fire protection measures implemented. In general, steel has good fire resistance properties due to its high melting point, but additional fireproofing measures such as fire-resistant coatings or insulation may be necessary to enhance its fire resistance rating. It is important to consult relevant building codes, fire protection standards, and engineering specifications to determine the specific fire resistance rating of steel angles in a given application.

- Q: Can steel angles be used for decorative purposes?

- Yes, steel angles can definitely be used for decorative purposes. Steel angles are versatile and can be shaped and formed into various designs and patterns, making them a popular choice for adding a decorative touch to interior and exterior spaces. They can be used to create decorative accents such as trim, frames, and brackets. Additionally, steel angles can be easily painted or powder-coated in different colors to match any desired aesthetic. The durability and strength of steel angles also ensure that they will withstand the test of time, making them a practical and attractive option for decorative applications.

- Q: Can steel angles be used in mezzanine or raised platform construction?

- Yes, steel angles can be used in mezzanine or raised platform construction. Steel angles provide structural support and stability, making them a suitable choice for such applications.

- Q: Can steel angles be welded or joined together?

- Steel angles are capable of being welded or joined together. Welding is a frequently utilized technique for connecting steel angles, as it establishes a robust and long-lasting bond. This procedure entails melting the edges of the angles and subsequently fusing them using a welding electrode. By means of welding, a secure connection is not only formed between the steel angles but structural integrity is also guaranteed. To maintain the joint's quality and strength, it is imperative to adhere to appropriate welding procedures and techniques. Furthermore, depending on the particular application and requirements, steel angles can also be connected using alternative methods such as bolting or riveting.

- Q: Can steel angles be used in equipment supports?

- Yes, steel angles can be used in equipment supports. They provide structural stability and are commonly used in various industries to support equipment and machinery.

- Q: What is the maximum length of a steel angle?

- The maximum length of a steel angle can vary depending on several factors such as the manufacturing process, the available raw materials, and the specific requirements of the project. However, in general, steel angles are typically available in standard lengths ranging from 20 feet to 40 feet. These lengths are commonly used for construction purposes and can be easily transported and installed on-site. It's important to note that customized lengths can also be fabricated based on specific project needs, but they may require additional time and cost. Therefore, it is recommended to consult with a steel supplier or manufacturer to determine the maximum length available for a steel angle based on the desired specifications.

- Q: Can steel angles be used for conveyor systems?

- Yes, steel angles can be used for conveyor systems. Steel angles are commonly used in construction and industrial applications due to their strength, durability, and versatility. In conveyor systems, steel angles are often used to provide structural support and stability to the conveyor framework. They can be used to connect various components of the conveyor system, such as the conveyor belt, rollers, and motor, ensuring proper alignment and smooth operation. Additionally, steel angles can be easily fabricated and customized to meet specific design requirements, making them a suitable choice for conveyor systems of different sizes and configurations.

Send your message to us

Angle steel, small angle, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords