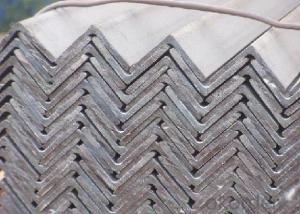

Q235B Small angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Q235B Small angle, angle steel, galvanized angle steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Q235B Small angle, angle steel, galvanized angle steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Q235 Small angle, angle steel, galvanized angle steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description:

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse.

Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two.

Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 312.5px for large angle steel, 312.5px - 125px for the medium angle, length of 125px for smallangle.

Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series.

Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m.

Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125

Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can steel angles be used for manufacturing support brackets?

- Yes, steel angles can be used for manufacturing support brackets. Steel angles are commonly used in construction and manufacturing industries due to their strength, durability, and versatility. They provide excellent support and stability, making them ideal for creating brackets that can withstand heavy loads and provide structural support.

- Q: What are the different methods for cleaning steel angles?

- To effectively clean steel angles, one can employ various methods: 1. Mechanical Cleaning: By utilizing tools like wire brushes, sandpaper, or abrasive wheels, one can physically scrub away dirt, rust, or contaminants from the steel angles. This method is ideal for light cleaning and can be done manually or with the assistance of power tools. 2. Chemical Cleaning: Stubborn stains, rust, or corrosion on steel angles can be eliminated using chemicals. Acid-based cleaners, such as phosphoric acid or hydrochloric acid, are commonly employed for this purpose. It is crucial to handle these chemicals with care and follow the manufacturer's instructions to ensure safety and prevent any damage to the steel. 3. Electrolytic Cleaning: This method involves immersing the steel angles in an electrolyte solution and applying an electrical current. The electrical current causes the rust or contaminants to dissolve and separate from the surface. Electrolytic cleaning is particularly effective for heavily rusted steel angles, but specialized equipment may be required. 4. High-Pressure Water Cleaning: By utilizing high-pressure water jets, dirt, grime, and loose rust can be effectively removed from steel angles. This environmentally friendly method does not require the use of chemicals. However, it may not be as effective for stubborn stains or heavy corrosion. 5. Blasting: Blasting entails propelling abrasive particles, such as sand, grit, or beads, at high speeds onto the surface of the steel angles. This process aids in the removal of rust, paint, and other contaminants. It is commonly used for heavy-duty cleaning or surface preparation before painting or coating. Choosing the appropriate method depends on the level of contamination, the condition of the steel angles, and the desired outcome. In some instances, a combination of methods may be necessary to achieve optimal results.

- Q: What is the maximum deflection allowed for a steel angle beam?

- The maximum deflection allowed for a steel angle beam typically depends on the specific design requirements, loading conditions, and industry standards. To determine the maximum deflection, engineers consider factors such as the beam's span, material properties, and the desired level of rigidity. Therefore, there is no standard maximum deflection for all steel angle beams, as it varies based on the specific application and design considerations.

- Q: What are the standard lengths for steel angles?

- Steel angles come in a range of standard lengths, which can vary depending on the manufacturer and project requirements. Commonly available options include 20 feet, 30 feet, and 40 feet. Additionally, it is worth mentioning that steel angles can be custom cut to fit specific application needs.

- Q: Are steel angles available in different finishes?

- Yes, steel angles are available in different finishes. Common finishes for steel angles include mill finish, hot-dip galvanized, powder-coated, and painted finishes.

- Q: How do you determine the load-bearing capacity of a steel angle?

- The load-bearing capacity of a steel angle can be determined by considering factors such as the material properties of the steel, the dimensions and shape of the angle, and the specific application requirements. It often involves analyzing the structural design, performing calculations, and consulting relevant engineering codes and standards to ensure the angle can safely support the intended loads without failure or deformation.

- Q: Are steel angles suitable for use in high-rise buildings?

- Yes, steel angles are suitable for use in high-rise buildings. Steel angles are commonly used as structural elements in high-rise buildings due to their excellent strength, durability, and versatility. They are able to withstand heavy loads and provide structural support, making them ideal for use in beams, columns, and bracing systems. Steel angles can be easily fabricated and installed, allowing for efficient construction processes. Additionally, steel angles can be designed in various sizes and shapes to meet specific structural requirements, providing flexibility in design and construction. Overall, steel angles are a reliable and cost-effective choice for high-rise buildings as they offer the necessary strength and stability required for such structures.

- Q: What are the different types of steel angle profiles?

- There are several different types of steel angle profiles, including equal angle, unequal angle, L-shaped angle, and structural angle. Each profile has its own specific dimensions and uses in various applications.

- Q: Are there any environmental concerns related to the production or disposal of steel angles?

- Yes, there are several environmental concerns related to the production and disposal of steel angles. Firstly, the production of steel angles requires large amounts of energy and raw materials, such as iron ore and coal. The extraction of these resources can have detrimental effects on the environment, including habitat destruction, deforestation, and air and water pollution. Additionally, the manufacturing process itself emits greenhouse gases and other pollutants, contributing to climate change and air pollution. Furthermore, the disposal of steel angles can be problematic. Steel is not easily biodegradable and can take hundreds of years to decompose. Improper disposal, such as landfilling or incineration, can lead to the release of toxic substances and contribute to soil and water contamination. To mitigate these environmental concerns, several measures can be taken. Firstly, improving the efficiency of steel production processes can reduce energy consumption and emissions. The use of recycled steel in the production of steel angles can also help decrease the demand for raw materials and reduce environmental impacts. Additionally, implementing proper waste management and recycling programs can minimize the environmental footprint of steel angle disposal. Overall, while steel angles are essential in various industries and construction, their production and disposal can have significant environmental implications. It is crucial to prioritize sustainable practices and technologies to mitigate these concerns and promote a more environmentally friendly approach to steel angle production and disposal.

- Q: How do you inspect and measure the dimensions of a steel angle?

- To inspect and measure the dimensions of a steel angle, you can use various tools and techniques. Firstly, you can visually examine the angle to ensure it is free from any visible defects or deformities. Next, you can use a tape measure or calipers to accurately measure its length, width, and thickness. Additionally, a protractor can be used to measure the angle's degree of bend. To ensure precise measurements, it is recommended to repeat the process multiple times and take an average value.

Send your message to us

Q235B Small angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords