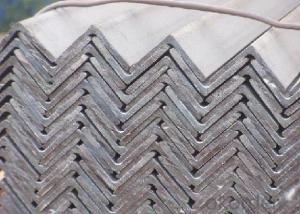

Q235 Small angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Q235 Small angle, angle steel, galvanized angle steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Q235 Small angle, angle steel, galvanized angle steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Q235 Small angle, angle steel, galvanized angle steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Description:

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse.

Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two.

Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 312.5px for large angle steel, 312.5px - 125px for the medium angle, length of 125px for smallangle.

Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series.

Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m.

Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125

Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: Can steel angles be used for overhead support in industrial settings?

- Yes, steel angles can be used for overhead support in industrial settings. Steel angles are versatile and strong structural components that can provide the necessary support for various overhead applications. They are commonly used in the construction industry for their ability to bear heavy loads and withstand high levels of stress. Steel angles are often employed in the construction of frameworks, trusses, and supports for overhead conveyors, cranes, piping systems, and other industrial equipment. Their durability, resistance to corrosion, and ability to be easily welded or bolted make them an ideal choice for providing overhead support in industrial settings.

- Q: How do you protect steel angles during transportation?

- To ensure the safety and prevent damage of steel angles during transportation, there are several measures that can be taken. Firstly, it is crucial to package the steel angles securely in a manner that reduces movement and eliminates direct contact with other objects that could cause scratches or dents. This can be achieved by utilizing suitable packaging materials like protective films, foam padding, or cardboard sheets. Furthermore, proper stacking and arrangement of the angles in the transportation vehicle is essential to avoid shifting during transit. They should be placed on a stable and level surface, and if multiple layers are required, interlayer materials such as wooden boards can be utilized to provide stability and distribute the weight evenly. Considering the climate conditions during transportation is also vital. If the steel angles are being transported in an open vehicle, they must be adequately covered with waterproof tarpaulins to protect against rain, snow, or other weather elements. Even if the angles are being transported in a closed vehicle, it is still important to ensure proper ventilation to prevent condensation and the formation of rust. Lastly, careful handling and proper loading/unloading procedures are crucial to safeguard the steel angles from impacts and accidents. The use of appropriate lifting and handling equipment, such as cranes or forklifts, should be implemented to minimize any potential damage during these processes. By adhering to these protective measures, the steel angles can be safeguarded during transportation, ensuring they reach their destination in optimal condition, ready for use or further processing.

- Q: What is the meaning of the number of angle steel

- The two sides of an equal angle steel are equal in width. The specifications are expressed in millimeters of edge width * edge width * edge thickness. Such as "/ 30 x 30 x 3", that is 30 mm width equal angle, edge thickness of 3 mm. The model can also be used, also the title number, number is the number of centimeters wide, such as the No. 3 angle angle 3#.

- Q: What are the different types of steel angle connections?

- There are several different types of steel angle connections, including bolted connections, welded connections, and hybrid connections. Bolted connections involve using bolts and nuts to connect steel angles together. Welded connections involve melting the steel angles together using heat and a welding process. Hybrid connections combine elements of both bolted and welded connections, using a combination of bolts and welding to secure the steel angles together.

- Q: What are the different test methods used to evaluate steel angles?

- Some of the different test methods used to evaluate steel angles include tensile testing, bend testing, impact testing, hardness testing, and dimensional inspection.

- Q: What is the minimum thickness for a steel angle bracket?

- The minimum thickness for a steel angle bracket can vary depending on the specific application and load requirements. However, in general, a minimum thickness of 1/8 inch (3.18 mm) is often considered standard for most angle brackets.

- Q: Can steel angles be used as lintels or supports for openings?

- Yes, steel angles can be used as lintels or supports for openings. Steel angles are commonly used in construction as structural elements due to their strength and durability. When used as lintels or supports for openings such as doors and windows, steel angles provide the necessary structural support to bear the load above the opening. They can be installed horizontally above the opening, with one leg of the angle bearing against the wall on either side. The load from the structure above is transferred to the steel angle, which in turn distributes the load to the surrounding walls. Steel angles are a popular choice for lintels and supports due to their high load-bearing capacity and resistance to bending and twisting forces.

- Q: Do steel angles require any special maintenance?

- No special maintenance is needed for steel angles, but their lifespan can be prolonged with proper care and attention. It is recommended to regularly clean them to remove dirt, debris, and corrosive substances. Additionally, it is important to promptly address any signs of rust, cracks, or damage to prevent further deterioration. To prevent corrosion and extend the life of the steel angles, applying a protective coating or paint is advisable. In general, steel angles require minimal maintenance, but regular inspections and maintenance practices are crucial for optimal performance and longevity.

- Q: Are steel angles suitable for high-temperature applications?

- Yes, steel angles are suitable for high-temperature applications. Steel is known for its high strength and durability, and it retains its structural integrity even at elevated temperatures. Additionally, steel angles can withstand thermal expansion and contraction without deformation or failure, making them a reliable choice for high-temperature environments.

- Q: Are steel angles resistant to earthquakes?

- Seismic-resistant construction can be achieved by utilizing steel angles, which possess high strength and ductility, making them suitable for this purpose. Often referred to as steel L-shaped beams, these steel angles are commonly employed in structural applications to provide support and reinforcement. During an earthquake, the utilization of steel angles aids in the even distribution of seismic forces throughout the structure, thereby reducing the occurrence of concentrated stress points. The L-shape design of these steel angles allows them to effectively resist bending and twisting forces, which are frequently encountered during seismic events. Moreover, steel angles can be interconnected and welded together to establish a rigid frame system, thereby enhancing their capability to withstand seismic forces. Such a system effectively absorbs and dissipates energy resulting from vibrations caused by earthquakes, ultimately minimizing any potential damage inflicted upon the structure. Nevertheless, it is crucial to acknowledge that the overall seismic resistance of a structure is contingent upon several factors, including its design, construction methods, and adherence to building codes and regulations. While steel angles alone cannot ensure complete protection against earthquakes, their integration into a well-designed seismic-resistant system significantly augments the structure's capacity to withstand seismic forces.

Send your message to us

Q235 Small angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 1000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords