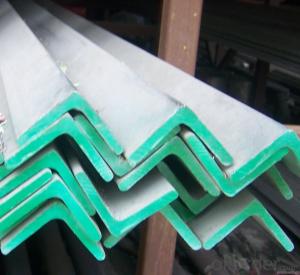

Small angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Angle called angle, the steel strip is perpendicular to each other on both sides into angular.Divided into equilateral angle steel and ranging from side angle. Two equilateral angle steel edge width is the same. The specification is expressed by edge width * width * thick edgenumber of millimeters. Such as "/ 30 x 30 x 3", namely that equilateral angle steel edge widthof 30 mm, 3 mm thick edge. Can also be used to model representation, model is the wideangle 3# cm, such as. The model does not represent the same type in different edge thickness size, thus in the contract and other documents on the angle of the edge width, edgethick size fill in complete, avoid alone represented by type. Hot rolled equilateral angle steelspecifications for 2#-20#. Angle according to the different needs of structure composed of a variety of stress components, can also be used as a component of the connections between the. Widely used in a variety of architectural and engineering structures, such as beams,bridges, towers, hoisting and conveying machinery, ships, industrial furnace, reactor,container frame and warehouse.

Mainly divided into equilateral angle steel, equilateral angle steel two categories, includingunequal angle can be divided into equal thickness and unequal thickness ranging from two.

Angle specifications with the side length of the size and edge thickness. At present, the domestic steel specifications for 2 - 20 cm in length, number of numbers, the same horn steel often have 2 - 7 different edge thickness. The actual size and inlet angle marked on both sides of the thickness and indicate the relevant standards. The general length of more than 12.5cm for large angle steel, 12.5cm - 5cm for the medium angle, length of 5cm for smallangle.

Inlet and outlet angle steel orders generally required the use specifications in the steel,carbon structural steel grades as appropriate. Is the angle in addition to standard number, nospecific composition and performance series.

Angle steel delivery length is divided into fixed length, size two, domestic steel length range is3 - 9m, 4 12M, 4 19m, 6 19m four range according to different specifications. Japanese steellength ranges from 6 to 15m.

Section of unequal angle height according to the long edge of the width to calculate the non equilateral angle steel. Refer to section angle and side length is not equal to the steel. Is a kind of angle steel. The length from 25mm * 16mm to 200mm * l25mm. By the hot rolling mill rolling in. General scalene angle steel specifications: thickness of 4-18mm / 50*32-- / 200*125

Equilateral angle steel is widely used in all kinds of metal structures, bridges, machinery manufacturing and shipbuilding industry, all kinds of architectural and engineering structures,such as beams, bridges, towers, hoisting and conveying machinery, ships, industrial furnace,reactor, container frame and warehouse etc.

- Q: Are steel angles load-rated?

- Yes, steel angles are load-rated. Steel angles are structural elements that are commonly used in construction and engineering applications. They are designed to withstand various types of loads, including axial loads, bending loads, and shear loads. The load rating of a steel angle refers to its maximum capacity to support a specific amount of load without failure. Load ratings for steel angles are determined through extensive testing and analysis, considering factors such as the material properties, geometry, and design standards. Load ratings are typically provided by manufacturers, and engineers use these ratings to ensure the structural integrity and safety of a project.

- Q: What are the different types of connections used for steel angles?

- Steel angles can be connected in several ways, depending on the application and load requirements. Here are some commonly used connections: 1. Welded Connection: The most frequently used connection for steel angles involves welding them to other members, such as beams or columns. These connections offer high strength and stiffness, making them suitable for heavy loads and structural purposes. 2. Bolted Connection: Another option is to bolt the steel angles to the connected members using bolts and nuts. Bolted connections are preferred when the structure may need to be disassembled or relocated. They offer flexibility, adjustability, and easy installation. 3. Riveted Connection: While not as commonly used nowadays, riveted connections were widely employed in older structures. Riveting involves joining the steel angle to other members using rivets. Although they require skilled labor for installation, riveted connections provide good strength and durability. 4. Clip Connection: A clip connection is a type of bolted connection where a clip or bracket is used to secure the steel angle to the supporting member. This allows for easy assembly and disassembly, making it suitable for temporary structures or situations requiring frequent modifications. 5. Shear Connection: Shear connections use shear plates or angles to connect the steel angle to the supporting member. These connections primarily transfer shear forces and provide sufficient strength and rigidity. 6. Cleat Connection: Cleat connections involve using a cleat plate, typically welded or bolted, to connect the steel angle to the supporting member. Cleat connections are commonly employed in industrial applications where heavy loads and high forces need to be transferred. When selecting the appropriate type of connection for steel angles, it is crucial to consider the specific requirements of the structure, including load capacity, design codes, and environmental conditions. Consulting with a structural engineer or referring to relevant design standards can ensure the proper selection and installation of the connection.

- Q: Can steel angles be used in earthquake-prone areas?

- Yes, steel angles can be used in earthquake-prone areas. Steel is a highly durable and strong material that can withstand seismic forces better than other construction materials like wood or concrete. Steel angles, in particular, are commonly used in seismic-resistant designs, as they provide structural support and help distribute the seismic forces throughout the building. Steel angles are designed to resist bending and twisting, making them ideal for earthquake-resistant construction. They are often used in the construction of steel moment frames, which are known for their ability to absorb and dissipate seismic energy. These frames provide a rigid structural system that helps to prevent the collapse of buildings during earthquakes. Furthermore, steel angles can be easily bolted or welded together, allowing for quick and efficient construction. This flexibility in design and construction makes steel angles a popular choice for earthquake-prone areas, where buildings need to be able to withstand high-intensity seismic events. However, it is important to note that the effectiveness of steel angles in earthquake-prone areas also depends on various factors, such as the specific building design, the quality of materials used, and adherence to building codes and regulations. Proper engineering and design considerations should always be followed to ensure the safe and reliable use of steel angles in such areas.

- Q: Can steel angles be used for support brackets in electrical installations?

- Indeed, support brackets for electrical installations can certainly utilize steel angles. In construction, steel angles are frequently employed and offer robust support for a multitude of applications, including electrical installations. These angles possess impressive strength and durability, enabling them to withstand the weight and stress imposed by supporting electrical components or fixtures. Furthermore, steel angles can be effortlessly affixed to walls, ceilings, or alternative surfaces, thereby establishing a reliable foundation for electrical equipment such as junction boxes, conduit, or cable trays. Furthermore, steel angles can be tailored and fabricated to accommodate precise installation specifications, rendering them an adaptable selection for support brackets in electrical installations.

- Q: Are steel angles susceptible to rusting?

- Yes, steel angles are susceptible to rusting.

- Q: What are the different methods of surface powder coating for steel angles?

- There are several methods of surface powder coating for steel angles. These methods are used to apply a protective and decorative layer of powder coating onto the steel surface. 1. Electrostatic Spraying: This is one of the most common methods used for powder coating steel angles. It involves using an electrostatic spray gun to apply the powder coating onto the surface. The powder particles are positively charged and are attracted to the grounded steel angle, resulting in a uniform and even coating. 2. Fluidized Bed: In this method, the steel angles are preheated and then dipped into a bed of fluidized powder particles. The heat from the steel causes the powder particles to melt and adhere to the surface, forming a smooth and durable coating. 3. Powder Coating Booth: This method involves placing the steel angles inside a powder coating booth. The booth is equipped with a powder spray gun that applies a fine mist of powder coating onto the surface. The angles are then cured in an oven to melt and bond the powder particles, creating a strong and long-lasting coating. 4. Electrostatic Fluidized Bed: This method combines the benefits of electrostatic spraying and fluidized bed techniques. The steel angles are preheated and then dipped into a bed of fluidized powder particles. An electrostatic charge is also applied to the powder particles, ensuring a more uniform and controlled coating. 5. Tribocharging: In this method, the powder coating is applied to the steel angles by frictional charging. The powder particles are passed through a tribocharging gun, which imparts a positive charge to the particles. The charged particles are then attracted to the grounded steel angle, resulting in a high-quality and consistent coating. Each of these methods has its own advantages and suitability for specific applications. The choice of the coating method depends on factors such as the desired finish, coating thickness, production volume, and cost considerations.

- Q: Can steel angles be used for pipe support systems?

- Yes, steel angles can be used for pipe support systems. Steel angles provide structural support and stability, making them suitable for holding and securing pipes in various applications.

- Q: Can steel angles be used for manufacturing bike racks?

- Yes, steel angles can be used for manufacturing bike racks. Steel angles provide strength and stability required to support the weight of bicycles and withstand outdoor conditions.

- Q: Are steel angles suitable for agricultural applications?

- Yes, steel angles are suitable for agricultural applications. They are commonly used in the construction of agricultural buildings, fences, and equipment due to their strength, durability, and versatility. Steel angles provide stability and support, making them ideal for various agricultural tasks such as framing structures, reinforcing corners, or creating sturdy connections.

- Q: What is the maximum load capacity for a steel angle bracket?

- The maximum load capacity for a steel angle bracket depends on various factors such as the dimensions of the bracket, the thickness and quality of the steel used, the method of installation, and the intended use of the bracket. Generally, steel angle brackets are designed to support heavy loads and can handle significant weight. However, it is crucial to consult the manufacturer's specifications or engineering guidelines for the specific bracket in question to determine its maximum load capacity. These specifications will provide accurate information on the maximum weight or load that the steel angle bracket can safely support without compromising its structural integrity.

Send your message to us

Small angle, angle steel, galvanized angle steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords