Rubber Cover EPDM Waterproof Membrane Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Coiled Rubber Waterproof Membrane for Ponds

Description for EPDM Rubber Waterproof Membrane :

GeoGard EPDM offers dependable performance for irrigation reservoirs, canals, aquaculture, dung pits, landfill covers,

waste water reservoirs, constructed wetlands, artificial snow reservoirs, storm water reservoirs, fire reservoirs and

large decorative ponds.

Main Features of EPDM Rubber Waterproof Membrane:

Superior durability

Seamless sheets in 1 piece

Very low life-cycle cost

Flame-free and easy installation

High flexibility and elongation

Environmentally friendly

Recovery of rainwater

Fire resistance

Specifications of EPDM Rubber Waterproof Membrane:

Material | EPDM Rubber |

Size | 1.2m (width)*20m (length) or customized, weldable type 2.05m or 4m width |

Thick | 1.2mm, 1.5mm, 2.0mm |

Type | Vulcanized & Weldable |

Pattern | Non-reinforced (homogeneous) |

Certificate | ISO9001/14001 |

Systems

Thanks to a variety of installation systems, the RubberGard EPDM Roofing System provides a solution for even the most challenging rooftops, for both renovation and new built applications.Products

The RubberGard EPDM Roofing System consists of a high performing EPDM rubber membrane and a complete range of accessories. The combination proven seaming technology offers a unique combination of features & benefits.Technical Information

CNBM Products provides to distributors, contractors, specifiers and building owners a comprehensive range of technical documents.Installation

It help the contractor installing the RubberGard EPDM Roofing System in accordance with requirements.Training

The RubberGard EPDM Roofing System is exclusively installed by approved roofing contractors that have successfully completed a training program in one of training centers.EPDM Project References

Operating since 3 decades in Europe and Asia, our Products has installed hundreds of thousands of EPDM roofs. The project portfolio includes a selection of major projects.

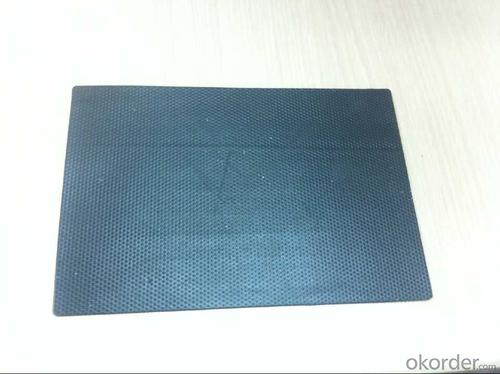

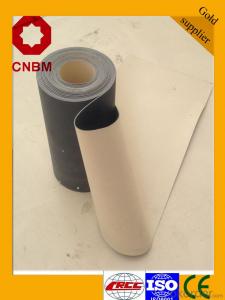

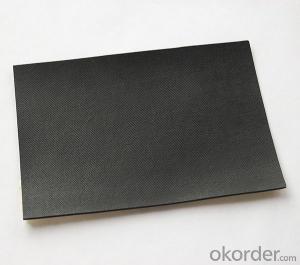

Images of EPDM Rubber Waterproof Membrane:

FAQ:

1. What are we supplying?

We are specialized in producing Colorful Asphalt Roof Shingle, SBS/APP modified bitumen waterproof membrane, Self adhesive bitumen waterproof membrane, PVC waterproofing membrane, EPDM rubber roofing membrane, Single Component Polyurethane Waterproof Coating, and Spray Polyurea Waterproof Coating

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: Can a waterproofing membrane be used for a dam?

- Certainly! A dam can employ a waterproofing membrane, a specialized material intended to obstruct the passage of water. This membrane is commonly employed in construction to establish a barrier against water intrusion. For a dam, which is an expansive structure constructed to retain water and form a reservoir, implementing an efficient waterproofing system is crucial in preventing any water leakage or infiltration. Applying a waterproofing membrane to the dam's surface offers an additional layer of defense against water penetration. Typically composed of rubber, PVC, EPDM, or bitumen, materials known for their exceptional water resistance, the membrane is layered multiple times to ensure a sturdy and long-lasting deterrent against water. It is specifically engineered to withstand the high water pressure exerted by the reservoir held behind the dam. Utilizing a waterproofing membrane preserves the dam's integrity, guaranteeing that water does not seep through the structure and cause harm to the surrounding areas. Furthermore, it aids in impeding erosion and seepage, which can weaken the dam over time. To summarize, a waterproofing membrane is indeed a viable solution for a dam, offering an effective means to ensure the dam remains watertight and structurally stable.

- Q: Elastomer modified asphalt waterproofing membrane for what purpose? Need to pay attention to a few things?

- Second, the construction quality Full adhesion to prevent wrinkles or hollowing; semi-adhesive attention to the unbonded to under fire, so that the membrane close to the base surface; empty shop attention around the adhesive, and pressurized. Hot melt adhesive, with the fire to be appropriate to the surface of the coil is not subject to black, avoid slow baking. Winter construction selection of low temperature flexibility than the construction temperature of 10 ℃ lower temperature products, and the coil stored at 0 ℃ above the place before use into the scene, handling to prevent throwing throw.

- Q: Is a waterproofing membrane resistant to impact damage?

- A waterproofing membrane is generally not designed to be resistant to impact damage. Its primary function is to prevent water infiltration and protect the underlying structure from moisture damage. While some membranes may have a certain level of impact resistance, it is not their main characteristic. To protect the membrane from impact damage, additional measures like installing protective layers or using impact-resistant materials may be necessary.

- Q: Can a waterproofing membrane be used for above-grade applications?

- Yes, a waterproofing membrane can be used for above-grade applications. Waterproofing membranes are commonly used in construction to prevent water infiltration and damage to structures. While they are often used for below-grade applications such as basements and foundations, waterproofing membranes can also be used above-grade on surfaces such as roofs, decks, and exterior walls. In above-grade applications, waterproofing membranes act as a barrier against moisture, preventing water from seeping into the structure. They are designed to withstand prolonged exposure to the elements, including rain, snow, and UV rays. By effectively sealing the surface, a waterproofing membrane helps to protect the structure from water damage, mold growth, and deterioration. There are different types of waterproofing membranes available for above-grade applications, including liquid-applied membranes, sheet membranes, and self-adhering membranes. These membranes are often made from materials such as modified bitumen, polyurethane, or rubberized asphalt, which provide excellent waterproofing properties. When installing a waterproofing membrane above-grade, proper surface preparation is essential. The surface needs to be clean, dry, and free from any contaminants that could compromise the adhesion of the membrane. Additionally, it is important to follow the manufacturer's instructions and guidelines for application techniques and recommended thickness. In summary, a waterproofing membrane can be used for above-grade applications to effectively protect structures from water infiltration and damage. By choosing the appropriate type of membrane and following proper installation procedures, it is possible to create a durable and reliable waterproofing system for above-grade surfaces.

- Q: Can waterproofing membranes be used on concrete dams?

- Yes, waterproofing membranes can be used on concrete dams. In fact, they are commonly used in the construction and maintenance of concrete dams to prevent water leakage and seepage. Waterproofing membranes are designed to create a barrier that is resistant to water penetration, protecting the concrete surface of the dam from damage caused by water. These membranes can be applied to both the interior and exterior surfaces of the dam, providing a reliable and long-lasting solution for waterproofing. Additionally, waterproofing membranes can also help to mitigate the risk of waterborne deterioration, such as freeze-thaw damage and corrosion of reinforcement, thereby extending the lifespan of the concrete dam.

- Q: How does a waterproofing membrane adhere to the surface?

- A waterproofing membrane adheres to the surface through various methods such as mechanical attachment, adhesive bonding, or heat welding. Mechanical attachment involves physically securing the membrane to the surface using fasteners, nails, or screws. Adhesive bonding utilizes a waterproofing adhesive to create a strong bond between the membrane and the surface. Heat welding involves melting the membrane's surface and fusing it with the substrate, creating a watertight seal. The specific method used depends on the type of membrane and the surface to which it is being applied.

- Q: Can a waterproofing membrane prevent leaks from occurring?

- Yes, a waterproofing membrane can prevent leaks from occurring. A waterproofing membrane is a thin layer of material that is applied to a surface to make it completely impermeable to water. It acts as a barrier, preventing water from seeping through and causing leaks. When properly installed and maintained, a waterproofing membrane can effectively protect various structures such as roofs, basements, bathrooms, or foundations from water damage. It is designed to withstand the forces of nature, including rain, snow, and moisture, and can significantly reduce the risk of leaks and water infiltration. However, it is important to note that the effectiveness of a waterproofing membrane also depends on the quality of the product, proper installation, and regular maintenance.

- Q: Are waterproofing membranes breathable?

- Yes, waterproofing membranes can be breathable. Breathability refers to the ability of a material to allow air or water vapor to pass through it while still preventing liquid water from penetrating. Many modern waterproofing membranes are designed to be breathable, allowing moisture vapor to escape from within while still keeping out liquid water. This is especially important in applications such as waterproof clothing, outdoor gear, or building materials where moisture control is necessary to ensure comfort and prevent the growth of mold or mildew. Breathable waterproofing membranes typically use advanced technologies such as microporous membranes or coatings that allow water vapor molecules to pass through while blocking larger liquid water molecules.

- Q: Are there any specific considerations for installing a waterproofing membrane on precast concrete surfaces?

- Installing a waterproofing membrane on precast concrete surfaces requires specific considerations. Here are some important points to remember: 1. Proper Surface Preparation: Before applying the waterproofing membrane, it is crucial to prepare the precast concrete surface correctly. This involves cleaning the surface, removing loose particles, and ensuring it is dry and free from any contaminants. 2. Compatibility: It is important to select a waterproofing membrane that is suitable for precast concrete surfaces. Some membranes may not adhere well or provide effective waterproofing on this type of substrate. Therefore, it is essential to choose a membrane specifically designed for use on precast concrete. 3. Ensuring Adhesion: Properly adhering the waterproofing membrane to the precast concrete surface is vital. It is important to carefully follow the manufacturer's instructions, including any surface priming or preparation requirements for optimal adhesion. Proper adhesion will prevent water infiltration and concrete damage. 4. Joint Treatment: Precast concrete surfaces often have joints between panels or components. These joints need proper treatment to maintain the system's waterproofing integrity. This may involve using joint sealants or tapes designed specifically for waterproofing purposes. 5. Considering Durability: Consider the durability and longevity of the waterproofing membrane. Precast concrete surfaces are exposed to various weather conditions and environmental factors. Therefore, it is crucial to choose a membrane that can withstand these conditions and provide long-term protection against water penetration. 6. Quality Assurance: It is recommended to work with experienced professionals or certified installers to ensure the proper installation of the waterproofing membrane on precast concrete surfaces. This minimizes the risk of installation errors and ensures that the waterproofing system performs as intended. By considering these factors, installing a waterproofing membrane on precast concrete surfaces can effectively protect the concrete from water damage and extend its lifespan.

- Q: Is a waterproofing membrane resistant to mold and mildew growth?

- Yes, a waterproofing membrane is typically resistant to mold and mildew growth. The membrane acts as a barrier against moisture, preventing it from seeping into the building materials and creating an environment for mold and mildew to thrive.

Send your message to us

Rubber Cover EPDM Waterproof Membrane Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords