EPDM Roof Waterproof Membrane with width 1.0m-4.0m for Roof Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane

Introduction for EPDM Waterproof Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Features for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

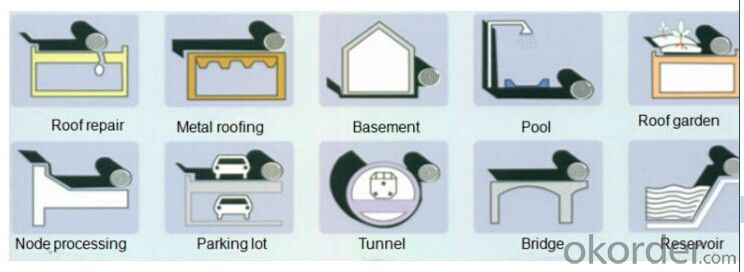

Application for EPDM Waterproof Membrane

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

Specification for EPDM Waterproof Membrane

Item | Thick(mm) | Width | Length(m) | Color |

Spe | 1.0—2.0 | 1.2m/2m/3m/4m | 20 | Black |

Deviation | -1 +15 | --1 | Multicolor |

Technical Sheet for EPDM Waterproof Membrane

EPDM Waterproof Membrane ASTM Standard : D-7465 | ||||

Property | Test Method | Units | Mininum ASTM | |

D-7465 | ||||

Sl | Eng | |||

Specific Gravity | ASTM D-792 | gm/cc | 1.1 | 1.1 |

Unit Weight | ASTM D-751 | kg/m2 | 1.3 | 0.27 |

Thickness Type 1 | ASTM D-412 | mm(in) | 1.02 | 0.04 |

Tensile Strength. Die C | ASTM D-412 | Mpa(psi) | 9 | 1305 |

Ultimate Elongation,Die C | ASTM D-412 | % | 300 | 300 |

Tear Resistance,Die C | ASTM D-624 | Kn/m(lbf/in) | 26.27 | 150 |

Puncture Resistance | ASTM D-4833 | N(lbs) | 133 | 30 |

Shore A Durometer | ASTM D-2240 | 65-10 | 65-10 | |

Ozone Resistance | ASTM D-1149 | No Crack | No Crack | |

Multiaxial Elongation | ASTM D-5617 | % | 100 | 100 |

Heat Aging 28 days at 240 degrees | ASTM D-573 | |||

Tensile Strength, Die C | ASTM D-412 | MPa(psi) | 8.3 | 1205 |

Ultimate elongation, Die C | ASTM D-412 | % | 200 | 200 |

Tear Resistance, Die C | ASTM-624 | Kn/m(lbf/in) | 21.9 | 125 |

Accelerated Aging Xenon Arc | ASTM G-155/G-151 | Pass | Pass | |

Brittleness Point | ASTM D-2137 | -45 °C | -49 °C F | |

Water Absorption | ASTM D-471 | % | +8,-2 | +8,-2 |

Water Vapor Permeability, max | ASTM E-96 | Permils | 2.0 | 2.0 |

Linear Dimensional Change,max | ASTM-D-1204 | % | +/-1.0 | +/-1.0 |

Chronic Toxicity Screening | EPA/600/4-89/001 | Method 1000.0 | Pass | Pass |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used in conjunction with fire protection systems?

- Yes, a waterproofing membrane can be used in conjunction with fire protection systems. While the primary function of a waterproofing membrane is to prevent water penetration, it can also act as a barrier to protect against fire. Some waterproofing membranes have fire-resistant properties, allowing them to withstand high temperatures and prevent the spread of fire. However, it is essential to ensure that the specific waterproofing membrane chosen is compatible and approved for use with the fire protection system in question.

- Q: Can a waterproofing membrane be used on breeze block surfaces?

- Yes, a waterproofing membrane can be used on breeze block surfaces. The membrane creates a barrier that helps prevent water penetration, protecting the breeze blocks from moisture damage.

- Q: Can a waterproofing membrane be used for underground bunkers?

- Yes, a waterproofing membrane can be used for underground bunkers. Waterproofing membranes are designed to provide a barrier against water infiltration, which makes them suitable for protecting underground structures such as bunkers from moisture and water damage.

- Q: Is a waterproofing membrane resistant to abrasion?

- A waterproofing membrane is generally able to resist abrasion. Its purpose is to create a protective barrier against water and moisture infiltration. These membranes are typically constructed from durable materials like PVC, TPO, or EPDM, which possess a high resistance to abrasion. Consequently, they can endure normal wear and tear that may arise during installation or due to foot traffic or other mechanical activities. Nonetheless, it is crucial to acknowledge that the level of resistance to abrasion can vary based on the specific type and quality of the membrane, as well as the conditions in which it is employed or utilized. Therefore, it is always advisable to refer to the manufacturer's guidelines and specifications to ensure the proper selection and installation of a waterproofing membrane.

- Q: Can a waterproofing membrane be used on vinyl surfaces?

- Yes, a waterproofing membrane can be used on vinyl surfaces. The membrane serves as a protective layer that prevents water from penetrating and damaging the vinyl material.

- Q: Can waterproofing membranes be used on concrete floors?

- Yes, waterproofing membranes can be used on concrete floors. They are commonly used to protect concrete surfaces from water damage and can be applied to both new and existing concrete floors to prevent water penetration and moisture-related issues such as mold, mildew, and deterioration.

- Q: How much does a waterproofing membrane cost?

- The cost of a waterproofing membrane can vary depending on several factors. The type of membrane, the size of the area to be waterproofed, and the complexity of the installation can all affect the price. On average, the cost of a waterproofing membrane can range from $1 to $5 per square foot. However, this is just a rough estimate and the actual cost can be higher or lower based on the aforementioned factors. For example, a basic sheet membrane made of PVC or EPDM might be on the lower end of the price range, while a liquid-applied membrane or a more advanced system like a bentonite clay membrane can be on the higher end. Additionally, the size of the area to be waterproofed will impact the cost. Larger areas will require more materials, labor, and time, which can increase the overall price. Complexity of the installation is another factor to consider. If the area is hard to access or requires extensive preparation work, such as removing existing materials or repairing cracks, the cost may be higher. It is recommended to consult with a professional waterproofing contractor who can assess your specific needs, provide an accurate estimate, and recommend the most suitable waterproofing membrane for your project.

- Q: Can a waterproofing membrane be used for railways or train stations?

- Yes, a waterproofing membrane can definitely be used for railways or train stations. Waterproofing membranes are commonly used in various construction projects to protect structures from water damage and ensure their longevity. In the case of railways and train stations, where there is constant exposure to weather elements and potential water infiltration, a waterproofing membrane can play a crucial role in preventing water ingress into the infrastructure. Waterproofing membranes are typically applied to different areas of the railway or train station, such as the underground tunnels, platforms, parking areas, and even the roofs. These membranes are designed to create a barrier against water and moisture, preventing them from seeping into the structure and causing damage. By preventing water infiltration, a waterproofing membrane helps to maintain the structural integrity of the railway or train station and extend its lifespan. In addition to protecting against water, waterproofing membranes also provide other benefits such as preventing the growth of mold and mildew, improving energy efficiency by reducing heat loss, and enhancing the overall durability of the structure. They are available in various types, including liquid-applied membranes, sheet membranes, and cementitious coatings, allowing for versatile application depending on the specific needs and requirements of the railway or train station project. Overall, the use of a waterproofing membrane in railways and train stations is highly recommended to ensure the long-term performance and maintenance of these critical infrastructures.

- Q: Can a waterproofing membrane be used in hospitals or healthcare facilities?

- Yes, a waterproofing membrane can be used in hospitals or healthcare facilities. It is often used in areas that require protection against moisture, such as bathrooms, operating rooms, and laboratories, to prevent water damage and maintain a hygienic environment.

- Q: Can waterproofing membranes be used on loading docks?

- Yes, waterproofing membranes can be used on loading docks. Waterproofing membranes are designed to provide a protective barrier against water infiltration, making them suitable for various applications, including loading docks. By installing waterproofing membranes on loading docks, it helps prevent water damage and leakage into the underlying structure, protecting the integrity and durability of the dock. Additionally, waterproofing membranes can also help enhance safety by reducing the risk of slips and falls that can occur due to wet surfaces on loading docks.

Send your message to us

EPDM Roof Waterproof Membrane with width 1.0m-4.0m for Roof Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords