PVC Waterproof Membrane for Outdoor Exhibition Hall High Tensile Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

The PVC waterproofing rolls formulas are based upon polyvinyl chloride resin with other assistants added to provide flexibility and stability such as anti-oxidant,absorbent of ultraviolet light, plasticizer and plastic filling agent.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

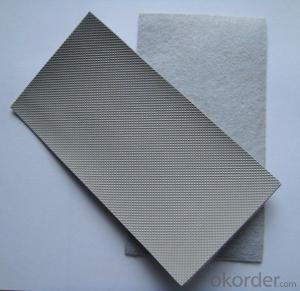

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

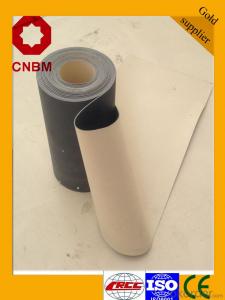

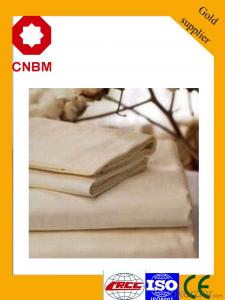

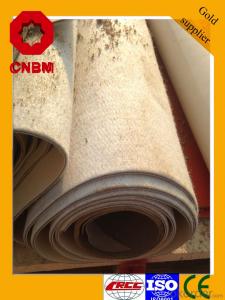

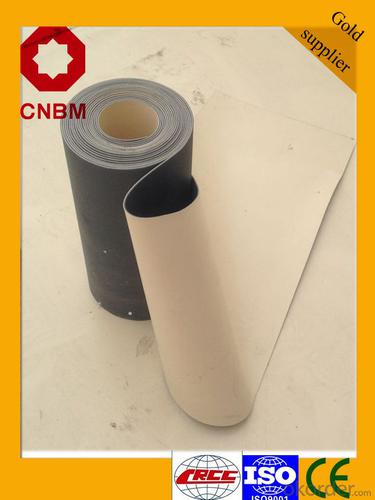

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used for temporary structures or tents?

- Yes, a waterproofing membrane can be used for temporary structures or tents. Waterproofing membranes are designed to provide a protective barrier against water, preventing it from penetrating the surface and causing damage. This makes them an ideal choice for temporary structures or tents, as they can effectively keep the interior dry during rain or other wet conditions. Additionally, waterproofing membranes are often lightweight and flexible, making them easy to install and remove, which is especially beneficial for temporary structures or tents that may need to be relocated or dismantled.

- Q: Can a waterproofing membrane be used for elevator shafts or equipment rooms?

- Elevator shafts and equipment rooms, being frequently exposed to moisture and water infiltration, can suffer significant damage to their equipment and structural components. Consequently, it becomes essential to implement a dependable waterproofing solution in order to prevent water penetration. One commonly employed method for safeguarding elevator shafts and equipment rooms against water damage is the use of a waterproofing membrane. This membrane, a thin layer of material, is applied to the surfaces of the shaft or room and functions as a barrier against water intrusion. Various materials like bitumen, PVC, or EPDM are typically utilized for these membranes due to their excellent waterproofing properties. To create a seamless and watertight enclosure, the waterproofing membrane is applied to all exposed surfaces, including walls, floors, and ceilings. Its purpose is to withstand hydrostatic pressure and prevent water from seeping into the elevator shaft or equipment room. Additionally, the membrane can also provide protection against other forms of moisture, such as condensation. Moreover, to enhance the effectiveness of the waterproofing membranes, they can be combined with other techniques like sealants and drainage systems. This multi-layered approach ensures a comprehensive waterproofing solution for elevator shafts and equipment rooms. In conclusion, a waterproofing membrane proves to be a suitable and reliable solution for protecting elevator shafts and equipment rooms from water infiltration. Its application creates a watertight enclosure, preventing potential damage to the equipment and structural components in these areas.

- Q: Can a waterproofing membrane be used for a residential building?

- Yes, a waterproofing membrane can be used for a residential building. A waterproofing membrane is a thin layer of material that is applied to the exterior walls, foundation, or roof of a building to prevent water from penetrating into the structure. It acts as a barrier against moisture, preventing water damage and mold growth, and can also help to improve the energy efficiency of the building by reducing heat loss. In a residential building, a waterproofing membrane can be used in various areas such as basements, bathrooms, balconies, roofs, and exterior walls. It is particularly useful in areas that are prone to water infiltration, such as basements where groundwater can seep in, or bathrooms where water splashes and steam can cause moisture issues. There are different types of waterproofing membranes available, including liquid-applied membranes, sheet membranes, and self-adhering membranes. These membranes are designed to be durable, flexible, and resistant to water, ensuring long-lasting protection for the residential building. By using a waterproofing membrane, homeowners can safeguard their property from water damage, structural issues, and health hazards associated with moisture intrusion. It is important to consult with professionals to determine the specific type of waterproofing membrane that is suitable for the residential building based on the location, climate, and potential sources of water infiltration.

- Q: Floor tiles on the terrace leak, can be directly on the brick shop SBS coil and then cast the cement?

- 4, SBS linoleum waterproof, when other waterproofing process is not suitable, you can choose SBS linoleum waterproof, and its advantages in: for a larger area and scope, more complex places, no regular terrace can be used, but the disadvantage is that SBS felt Waterproof is not extended, easy to aging, generally used in 3-5 years, and the construction should be very cautious, because the shop linoleum, the use of gasoline to spray the barbecue, it is easy to ignite the surrounding building materials, especially color steel insulation layer and Building insulation wall, are flammable materials, such as ignition, the consequences could be disastrous, so SBS linoleum waterproof as little as possible, with new materials to replace, even when used, be careful, do a good job before and after the construction arrangements.

- Q: Can a waterproofing membrane be used in conjunction with drainage systems?

- Yes, a waterproofing membrane can be used in conjunction with drainage systems. The membrane provides a barrier to prevent water penetration, while the drainage system helps to channel and remove any water that may accumulate. This combination ensures effective and comprehensive waterproofing for various applications such as basements, roofs, and underground structures.

- Q: Does a waterproofing membrane prevent mold and mildew growth?

- Yes, a waterproofing membrane can help prevent mold and mildew growth by creating a barrier that prevents moisture from seeping into walls, floors, or other surfaces. By keeping the area dry, it reduces the conditions necessary for mold and mildew to thrive. However, it is important to note that a waterproofing membrane alone may not completely eliminate mold and mildew, as proper ventilation and maintenance are also crucial in preventing their growth.

- Q: Can a waterproofing membrane be used for temporary structures or tents?

- Yes, a waterproofing membrane can be used for temporary structures or tents. It provides an effective barrier against water infiltration, helping to keep the interior dry and protected from outside elements. This can be especially useful in temporary structures or tents where water resistance is crucial for comfort and safety.

- Q: Can a waterproofing membrane be used for balconies and terraces?

- Yes, a waterproofing membrane can be used for balconies and terraces. Waterproofing membranes are often used in construction to protect these outdoor spaces from water damage and leakage. They provide an effective barrier against moisture and ensure the durability and longevity of balconies and terraces.

- Q: Can a waterproofing membrane be used for plant rooms?

- Yes, a waterproofing membrane can be used for plant rooms. Plant rooms often house machinery and equipment that require protection from water and moisture. Using a waterproofing membrane can help prevent water damage to the plant room and the equipment inside. It creates a protective barrier that keeps water from penetrating the walls, floors, and ceilings of the plant room. This can be especially important in areas where there is a higher risk of water leaks or condensation. Waterproofing membranes are designed to withstand various environmental conditions and can provide long-lasting protection for plant rooms.

- Q: Can a waterproofing membrane be used on stadium seating areas?

- Indeed, stadium seating areas can benefit from the application of a waterproofing membrane. Typically utilized to shield structures from water-related harm, such as roofs, basements, and decks, waterproofing membranes prove invaluable. Stadium seating areas, being frequently exposed to the elements like rain and snow, are susceptible to water damage if not adequately safeguarded. The implementation of a waterproofing membrane effectively thwarts water infiltration, thereby averting potential predicaments including mold proliferation, material deterioration, and structural impairment. It is crucial to select a top-notch waterproofing membrane specifically formulated for outdoor usage, capable of enduring heavy foot traffic, thus guaranteeing enduring protection for the stadium seating areas.

Send your message to us

PVC Waterproof Membrane for Outdoor Exhibition Hall High Tensile Strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords