Chinese Manufacturer Used In Roof PVC Waterproof Membrane In High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

The PVC waterproofing rolls formulas are based upon polyvinyl chloride resin with other assistants added to provide flexibility and stability such as anti-oxidant,absorbent of ultraviolet light, plasticizer and plastic filling agent.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

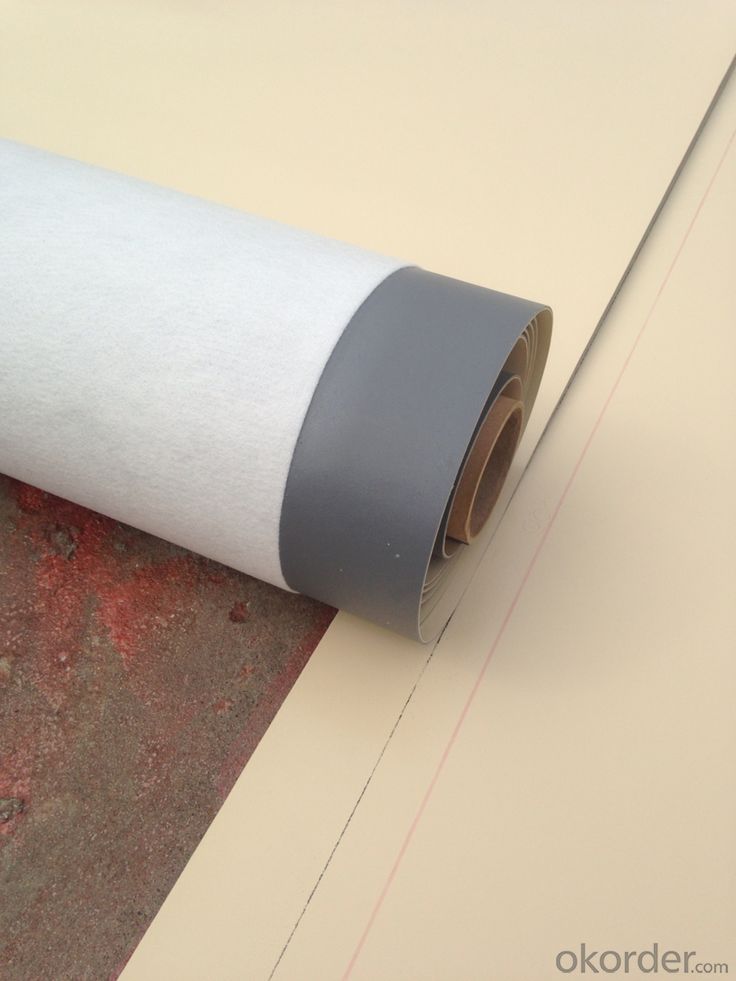

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used on precast brick block surfaces?

- Precast brick block surfaces can indeed benefit from the application of a waterproofing membrane. Such a membrane serves as a protective shield, safeguarding the bricks against water infiltration, which could otherwise lead to undesirable consequences like cracks, efflorescence, or the growth of mold. It is crucial to select a waterproofing membrane explicitly designed for masonry surfaces, as these membranes are specially formulated to adhere perfectly to the distinct properties of brick and block materials. Moreover, to guarantee the membrane's effectiveness, it is essential to adhere to proper surface preparation and application techniques.

- Q: Can a waterproofing membrane be used for underground electrical vaults?

- Yes, a waterproofing membrane can be used for underground electrical vaults. Waterproofing membranes are commonly used to protect underground structures from water infiltration, including electrical vaults. The membrane acts as a barrier to prevent water from seeping into the vault, which can help to protect the electrical equipment and prevent damage or malfunction.

- Q: Can a waterproofing membrane be used on tunnels with fire protection systems?

- Tunnels equipped with fire protection systems can indeed make use of a waterproofing membrane. It is actually quite common to recommend the use of a waterproofing membrane alongside fire protection systems in tunnels, as it adds an extra layer of safeguarding. The purpose of this membrane is to prevent any water from infiltrating the tunnel, as this could potentially harm the fire protection systems and undermine their effectiveness. By ensuring the tunnel remains watertight, the waterproofing membrane preserves the integrity and functionality of the fire protection systems, enabling them to fulfill their intended purpose in the event of a fire. Moreover, the waterproofing membrane can also serve as a barrier, impeding the spread of fire by blocking the passage of flames and smoke. Nonetheless, it is crucial to ensure that the chosen waterproofing membrane is compatible with the specific fire protection systems employed in the tunnel in order to ensure optimum performance and safety.

- Q: Can a waterproofing membrane be used on modified bitumen roofs?

- A waterproofing membrane is capable of being utilized on modified bitumen roofs. In fact, it is quite customary to apply a waterproofing membrane on top of modified bitumen roofs in order to provide an extra layer of defense against water infiltration. This is particularly crucial in regions where heavy rainfall occurs or where the roof is frequently exposed to water. The waterproofing membrane serves to seal any potential cracks or openings in the modified bitumen roofing system, thereby preventing water from penetrating and causing damage to the underlying structure. Moreover, the waterproofing membrane can also bolster the overall durability and longevity of the roof by shielding it from the detrimental effects of moisture.

- Q: Can a waterproofing membrane be used for a basement floor slab?

- Yes, a waterproofing membrane can be used for a basement floor slab. A waterproofing membrane is designed to prevent water and moisture from seeping into the surface it is applied to. This makes it an ideal solution for protecting basement floor slabs from potential water damage. By installing a waterproofing membrane on the basement floor slab, you can create a barrier that effectively prevents water penetration, reducing the risk of water damage, mold growth, and structural issues. Additionally, a waterproofing membrane can also serve as a vapor barrier, preventing moisture from rising up through the slab and causing issues such as dampness or high humidity levels in the basement. Overall, using a waterproofing membrane for a basement floor slab is a smart choice to ensure the long-term durability and protection of the basement.

- Q: Are waterproofing membranes suitable for below-grade applications?

- Yes, waterproofing membranes are suitable for below-grade applications. These membranes are specifically designed to prevent water infiltration into basements, foundations, and other below-ground structures. They provide a protective barrier against groundwater, ensuring the integrity and longevity of the structure.

- Q: Does a waterproofing membrane also protect against moisture and humidity?

- Yes, a waterproofing membrane is specifically designed to protect against moisture and humidity. It acts as a barrier, preventing water penetration and moisture buildup, thus effectively safeguarding the underlying structure from potential damage caused by moisture and humidity.

- Q: How does a waterproofing membrane handle moisture from the ground?

- To effectively manage moisture from the ground, a waterproofing membrane is designed to create a barrier that stops water infiltration. It is typically constructed using impermeable materials like rubber, bitumen, or modified asphalt. When correctly implemented, the membrane forms a continuous, watertight layer that prevents water from seeping through the foundation or walls. Typically, the membrane is placed on the exterior side of a building's foundation, where it serves as a protective shield against groundwater. It is applied directly onto the concrete or masonry surface, forming a seamless and durable waterproofing layer. To ensure its long-term durability, the membrane is then covered with a protective layer, such as soil or backfill. In addition to being impermeable, a waterproofing membrane also incorporates features that enable it to handle moisture effectively. For example, it may include built-in channels or dimples that facilitate the drainage of water away from the foundation, preventing the accumulation of hydrostatic pressure. Some membranes even possess self-healing properties, allowing them to seal minor punctures or cracks that may develop over time. Overall, a properly installed waterproofing membrane serves as a dependable barrier against ground moisture. It safeguards the structure from water damage, prevents the growth of mold and mildew, and maintains a dry and healthy indoor environment. However, it is crucial to ensure correct installation by adhering to the manufacturer's guidelines and seeking assistance from experienced professionals to guarantee its effectiveness.

- Q: Can a waterproofing membrane be used for a fountain waterproofing system?

- Yes, a waterproofing membrane can be used for a fountain waterproofing system. A waterproofing membrane is a barrier that is designed to prevent water from infiltrating or leaking through the structure it is applied to. This membrane is typically made of materials such as rubber, PVC, or bitumen, and is applied to surfaces such as concrete, stone, or masonry. In the case of a fountain waterproofing system, a waterproofing membrane can be applied to the interior surfaces of the fountain to prevent water from seeping through and causing damage. The membrane acts as a protective layer that ensures the water remains contained within the fountain, preventing leaks or seepage. It is important to select a waterproofing membrane that is specifically designed for fountains or water features. This type of membrane should be able to withstand constant exposure to water, as well as the specific conditions and chemicals that may be present in a fountain environment. Additionally, proper installation and maintenance are crucial to ensure the effectiveness of the waterproofing membrane. It is recommended to consult with a professional waterproofing contractor or fountain specialist to assess the specific requirements of your fountain and to determine the most suitable membrane and installation method. Overall, a waterproofing membrane can be an effective solution for ensuring the waterproofing of a fountain system, helping to maintain its structural integrity and prevent water-related damage.

- Q: Are waterproofing membranes resistant to alkalis?

- Waterproofing membranes, in general, exhibit resistance to alkalis. Alkalis, substances with high pH levels like sodium hydroxide or potassium hydroxide, can be present in various construction materials including concrete. The main purpose of waterproofing membranes is to create a protective barrier against water and other potentially harmful substances. They are typically manufactured using materials such as modified bitumen, PVC, or EPDM, which possess excellent alkali resistance. This resistance ensures that the waterproofing membrane remains intact and efficient even when exposed to alkaline substances. When dealing with materials or environments containing high levels of alkalis, it is crucial to choose a waterproofing membrane specifically designed for alkali resistance.

Send your message to us

Chinese Manufacturer Used In Roof PVC Waterproof Membrane In High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords