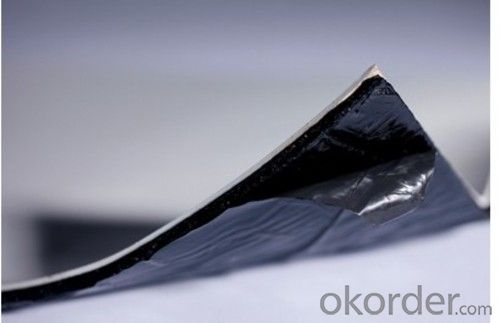

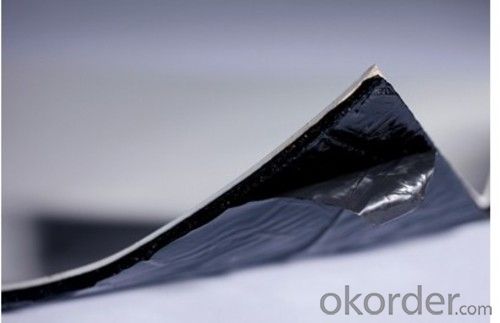

EPDM Waterproofing Rubber Membrane Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Features

1 Excellent physical and mechanical performance

2 High tearing resistance

3 Good deformation adaptability

4 High puncture resistance

5 High aging resistance

6 High UV resistance

Application

l Roofs, Basement, Toilet

l Industrial and civil building waterproofing

l Geosynthetic liner for swimming pool, channels, irrigation system

l Especially suit for projects with high requirements in durability, anti-corrosion and deformation

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for a basement floor moisture barrier?

- Indeed, a basement floor moisture barrier can be established by utilizing a waterproofing membrane. The primary purpose of a waterproofing membrane is to impede the penetration of water into surfaces, thereby offering a highly efficient solution for safeguarding a basement floor against moisture. Through the application of a waterproofing membrane, a protective barrier is formed to prevent water from infiltrating the concrete floor, subsequently minimizing the potential hazards of mold, mildew, and water damage. To attain optimal effectiveness, it is crucial to ensure the accurate installation of the waterproofing membrane, covering the entirety of the basement floor. Moreover, it is advisable to seek guidance from a professional to ascertain the most appropriate type of waterproofing membrane suitable for your specific basement floor and moisture conditions.

- Q: Can a waterproofing membrane be used for tunnels or subway systems?

- Tunnels and subway systems frequently encounter water infiltration as a result of the soil conditions or groundwater levels in their vicinity. To counteract this issue, a waterproofing membrane is commonly employed. This membrane serves as a protective shield, effectively obstructing water from permeating into the tunnels or subway systems. Its installation is typically carried out on the outer surfaces of the tunnel walls and roof, establishing an impervious seal. By doing so, it aids in the prevention of corrosion, decay, and harm to the structural components of the tunnels, guaranteeing the durability and safety of these subterranean infrastructures.

- Q: Can a waterproofing membrane be used on wood surfaces?

- Indeed, wood surfaces can benefit from the application of a waterproofing membrane. These membranes are specifically engineered to form a barricade against water infiltration, effectively safeguarding the surface they are applied on. While their typical usage involves concrete or masonry surfaces, they can also be utilized on wood surfaces to shield them from moisture-induced harm. By employing a waterproofing membrane on wood surfaces, the absorption of water can be curtailed, thus preventing potential issues such as rot, warping, or decay. It is crucial to select a waterproofing membrane that is specifically tailored for wood, as it will furnish the necessary protection while allowing the wood to breathe and maintain its innate characteristics.

- Q: Can a waterproofing membrane be used on foam block surfaces?

- Foam block surfaces can benefit from the use of a waterproofing membrane. Foam blocks, like expanded polystyrene (EPS) or extruded polystyrene (XPS), are commonly utilized for insulation in buildings. However, they are not naturally waterproof and can absorb moisture if exposed. To safeguard against water infiltration and potential harm, the application of a waterproofing membrane is recommended. This membrane acts as a protective barrier, preventing water from penetrating the foam and safeguarding it against issues caused by moisture, such as mold, mildew, or degradation. Selecting a waterproofing membrane that is compatible with foam block surfaces is crucial, and it is essential to adhere to the manufacturer's instructions for proper application. It is also advisable to seek guidance from a professional or building engineer to ensure the correct waterproofing solution is chosen for the specific foam block application.

- Q: Can a waterproofing membrane be used for oil or gas industry applications?

- Yes, a waterproofing membrane can be used for oil or gas industry applications. Waterproofing membranes are designed to provide a barrier against water penetration, but they can also be effective in preventing the leakage of oil or gas. These membranes are often used in various industrial applications, including oil and gas pipelines, storage tanks, and containment areas, to ensure the protection and containment of hazardous substances.

- Q: Can a waterproofing membrane be used for theme parks or amusement centers?

- Yes, a waterproofing membrane can be used for theme parks or amusement centers. These types of facilities often have water features, pools, or water rides that require effective waterproofing to prevent leaks or water damage. Waterproofing membranes provide a reliable and durable solution to keep these areas watertight, ensuring the safety and longevity of the park or center.

- Q: Can a waterproofing membrane be used in saunas?

- Indeed, a sauna can utilize a waterproofing membrane. Given that saunas consist of environments abundant in moisture, implementing a waterproofing membrane can effectively avert water damage and shield the underlying structure against moisture infiltration. The membrane functions as a barrier, effectively impeding the permeation of water and mitigating potential complications like mold growth, mildew formation, and rot. The selection of a waterproofing membrane specifically engineered for high-moisture regions, capable of withstanding the intense heat and humidity characteristic of saunas, is of utmost importance. Additionally, proper installation and adherence to manufacturer guidelines are essential to guarantee the efficiency and durability of the waterproofing membrane within a sauna setting.

- Q: Are waterproofing membranes UV resistant?

- Yes, most waterproofing membranes are UV resistant. UV resistance is an essential property for waterproofing membranes as they are often exposed to sunlight. UV rays can cause degradation and deterioration of materials over time, leading to decreased effectiveness and durability of the membrane. Therefore, manufacturers of waterproofing membranes incorporate UV-resistant additives or coatings into their products to protect them from the harmful effects of UV radiation. This UV resistance helps to maintain the integrity and performance of the membrane, ensuring long-lasting protection against water penetration.

- Q: Can a waterproofing membrane be used in conjunction with flooring materials?

- Indeed, flooring materials can be used in conjunction with a waterproofing membrane. It is actually quite common to advise the application of a waterproofing membrane while installing specific types of flooring, particularly in wet spaces such as bathrooms, kitchens, or basements. The waterproofing membrane functions as a shield against moisture, effectively thwarting water penetration that could potentially harm the flooring material or the subfloor. It provides safeguard against leaks, spills, and even excessive moisture in the atmosphere. Through the utilization of a waterproofing membrane, you can guarantee the longevity and sturdiness of your flooring, simultaneously upholding a waterproof and moisture-resistant environment.

- Q: Is a waterproofing membrane resistant to mold and mildew growth?

- Yes, a waterproofing membrane is typically resistant to mold and mildew growth. The membrane acts as a barrier against moisture, preventing it from seeping into the building materials and creating an environment for mold and mildew to thrive.

Send your message to us

EPDM Waterproofing Rubber Membrane Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords