Rolled Steel Coils - Pre-Painted Galvanized Steel Coil EN10169 Stone 9

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pre-painted Galvanized Steel Coils/ PPGI/GI

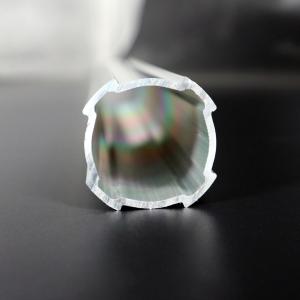

I Specifications:

1.Thickness:0.16-2.0mm

2.Width:600-1500mm

3.Material: SGCC,SGCD,SECC,SECD,DX51D+Z

4.Zinc coating:40-275G/M2

5.Surface Structure: galvanized ,zero spangle, regular spangle or normal spangle

6.Surface treatment: chromated and oiled, chromated and non-oiled

7.Color:all RAL series

II Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing,such as the embossed PPGI,printed PPGI&punching PPGI

4.economy and practicality

III Applications:

Household Appliance:

1.Refrigerator shutter &side panels, Washer, Freezers, Air conditions,

2.Rice Cooker, Microwave Ovens, Water Heaters, Sterilization Cabinets, Range Hoods

3.Computer Panels , DVD/DVB panels, TV back panel etc.

Teaching Board: whiteboard, blackboard, green board(chalk board).

Indoor Decoration: Fireproof Door, kitchen cabinet, wall decoration.

Shipping Industries: Ship, Fecht, Marine.

Elevator/Medical Equipment/Rubbish Bin.

Thickness:0.17mm-0.8mm

Width:600mm-1250mm

Prepainted Galvanized Steel Coil

- Q:How are steel coils used in the production of metal facades?

- Steel coils are used in the production of metal facades as the primary material. These coils are unwound and then processed through various manufacturing techniques, such as cutting, shaping, and forming, to create the desired facade panels. The steel coils provide strength, durability, and versatility, allowing for the creation of aesthetically pleasing and functional metal facades in various architectural applications.

- Q:I am using mild steel wire (very thin and bendable) for an art project, and would like to know if using a soldering torch is effective enough to get the job done. Or do I have to use a butane torch to heat the metal?BTW, is it better to use soft or hard solder?

- You can indeed by using the correct flux as normal soldering fluxes as used by plumbers will not work. I believe to solder steel it requires an acid flux which will corrode copper so when its done make sure its well cleaned afterwards and if possible apply a corrosion proofer afterwards ie paint or even petroleum jelly. I am curious as to why you would want to solder wire to a steel nail.

- Q:How are steel coils protected during shipping?

- Steel coils are protected during shipping through a variety of measures to ensure their safety and prevent damage. One common method is the use of steel coil cradles or saddles. These are specially designed structures that hold the coils securely in place and prevent them from shifting or rolling during transit. The cradles are typically made of sturdy steel or other durable materials and are specifically engineered to withstand the weight and pressure of the coils. In addition to the cradles, steel coils are often wrapped in protective materials such as plastic or paper. This wrapping acts as a barrier, shielding the coils from moisture, dust, and other potential contaminants that could affect their quality. The wrapping is typically applied tightly to the coils, ensuring that it stays in place throughout the shipping process. To further safeguard the coils, they are often loaded into shipping containers or onto flatbed trucks using specialized equipment. This equipment, such as coil hooks or lifting clamps, allows for safe and secure handling of the coils, minimizing the risk of accidents or damage during loading and unloading. In some cases, steel coils may also be packed into wooden or metal crates for added protection. These crates provide an extra layer of security and help to prevent any potential impacts or rough handling from causing damage to the coils. Overall, the protection of steel coils during shipping is of utmost importance to ensure that they arrive at their destination in optimal condition. By utilizing cradles, protective wrapping, specialized equipment, and additional packaging when necessary, the risk of damage is significantly reduced, allowing for a smooth and successful transportation process.

- Q:What are the different types of steel coil handling devices?

- There are several types of steel coil handling devices, including coil lifters, coil grabs, coil tongs, coil hooks, and coil C-hooks. These devices are designed to safely and efficiently handle steel coils of various sizes and weights, allowing for easy transportation and storage in industrial settings.

- Q:Suppose that the hardness of steel is uniformly distributed, taking on values between 50 and 80 on the Rockwell B scale.Compute the probability that the hardness of a randomly selected steel specimen is less than 60. a..462b..333c..500d.2e..750 Question 8 Refer to question 7. Compute the probability that the hardness of a randomly selected steel specimen is between 70 and 75.a..167b..500c..063d..100e..

- Suppose that the hardness of steel is uniformly distributed, taking on values between 50 and 80 on the Rockwell B scale. That would be... f(x) = 1/(80 - 50), 50 ≤ x ≤ 80 . . . . . 0 elsewhere Consider this following problem.. Compute the probability that the hardness of a randomly selected steel specimen is less than 60. Here, we have... P(x 60) Oh! Know that the mean and the standard deviation of the uniform distribution function are... ? = (a + b)/2 σ = (a - b)?/12 You should get... ? = 65 σ = 75 Now... P(z (60 - 65)/75) = P(z -0.07) Hence, you should get around 0.462. Good luck!

- Q:How are steel coils used in the production of construction components?

- Steel coils are used in the production of construction components in various ways. One common use is for the manufacture of steel beams and columns, which are essential structural elements in buildings and other large structures. The steel coils are processed and shaped into the desired dimensions, then cut and welded to form the beams and columns. Steel coils are also used in the production of roofing and wall cladding materials for construction. These coils are often coated with protective layers to enhance durability and resistance to corrosion. The coils are then shaped and formed into roofing sheets, wall panels, or siding materials that provide both aesthetic appeal and functional protection to the building. Another important application of steel coils in construction is for the production of reinforcing bars, commonly known as rebar. Rebar is used to provide strength and stability to concrete structures, such as foundations, slabs, and walls. The steel coils are processed and cut into specific lengths, then shaped and twisted to form the required reinforcement bars, which are then embedded within the concrete during construction. Furthermore, steel coils can be used in the production of various other construction components, such as pipes, tubes, and profiles. These components are used for plumbing, heating, ventilation, and other structural applications. The steel coils undergo different manufacturing processes, including rolling, welding, and shaping, to achieve the desired dimensions and properties of these components. In summary, steel coils play a crucial role in the production of construction components. They are used to manufacture steel beams, columns, roofing and wall cladding materials, reinforcing bars, pipes, tubes, and profiles. These components are vital for the construction industry, as they provide strength, durability, and functionality to buildings and other structures.

- Q:What are the benefits of using coated steel coils in roofing applications?

- There are several benefits of using coated steel coils in roofing applications. Firstly, coated steel coils offer exceptional durability and resistance to corrosion, making them highly suitable for outdoor use. This helps to prolong the lifespan of the roofing system and reduce maintenance costs. Additionally, the coatings provide excellent weather resistance, protecting the roof from harsh elements such as UV rays, rain, snow, and hail. Coated steel coils also offer a wide range of colors and finishes, allowing for greater design flexibility and aesthetic appeal. Furthermore, these coils are lightweight, which facilitates easier installation and reduces the overall weight load on the structure. Overall, using coated steel coils in roofing applications ensures long-lasting protection, enhanced aesthetics, and reduced maintenance requirements.

- Q:What are the dimensions of steel coils used in the railway equipment industry?

- The railway equipment industry utilizes steel coils with dimensions that can vary according to the specific application and requirements. However, there are commonly observed dimensions for these steel coils, typically ranging from 3 to 5 feet in width and 10 to 15 feet in length. Likewise, the thickness of the steel coils exhibits variation, spanning from 0.01 to 0.5 inches. It should be noted that these dimensions are not set in stone and may fluctuate based on the specific demands of the railway equipment industry, such as the type of equipment being produced or the distinct purpose of the steel coils.

- Q:When I got my AR-15 I was told that I should get either get Brass or Steel Case ammo and stick with one or the other, I was wondering why? It surely wouldn't damage anything switching back and forth between the two would it? I got steel case ammo and I have stuck with It and probably will either way, I was just wanting to know it I ever wanted to get some Hornady's or somthing like that.

- my uncle is a cop and he received't run metal case by skill of his ar. it actualy did reason it to jam, and he cleans it after each decision visit. the element with ars is they are very low tollerance and require softer metals which will push them round esier. by skill of the years, metal will also positioned on down your internals swifter than brass because brass is softer. some mags each once in a lengthy time period wont damage some thing, yet when i wouldnt completely use metal case in mine.

- Q:How are steel coils used in the production of agricultural trailers?

- Steel coils are used in the production of agricultural trailers as they are formed into various structural components such as frames, chassis, and supports. These coils are cut, shaped, and welded to create a sturdy and durable trailer structure that can withstand heavy loads and rough terrains commonly encountered in agricultural operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rolled Steel Coils - Pre-Painted Galvanized Steel Coil EN10169 Stone 9

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 2000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords