Hot Rolled Steel Coil Best Quality from China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

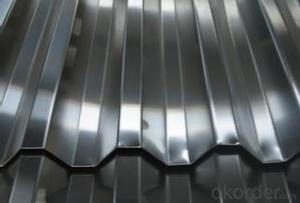

General Information of Hot Rolled Steel Coil

Rolled to its final dimensions while it’s hot enough to scale, our hot-rolled steel is an amalgamation of the various qualities of steel.

It can be in the form of plates, sheets and coils.

Our Hot-Rolled Steel Sheets and Coils are applied to a wide range of uses such as automobile, electrical appliance, machinery manufacturing, container manufacturing, shipbuilding, bridge, pipeline, and receive high acclaim from our customers for its excellent quality.

Specification of Hot Rolled Steel Coil

1. Thickness 14mm - 60mm

2. Width 1800mm - 2500mm

3. Sheets Length 6000mm - 12000mm

4. Internal Diameter 508mm or 610mm

5. Steel Grade Q235B, Q235C, Q235D, Q345B, SPHC 510L, Q345A, Q345E, SS400, Q345G, Q345F

6. FOB 620-720USD per ton

7. Standard ASTM

8. Rolling Precision A/B

9. Edge Q/BQ

Technical Information of Hot Rolled Steel Coil

Chemical Composition

C | Si | Mn | P | S |

0.04-0.05% | 0.01-0.02% | 0.18-0.22% | 0.014-0.016% | 0.006%-0.009% |

Technical Data

1. Yield Strength (Mpa) 280-320

2. Tensile Strength (Mpa) 340-390

3. Elongation 23%-41%

4. Reverse Impact 9J

5. T-bending ≥2T

6. Pencil Hardness ≥2H

7. Duration Of Salt Spray Test 500 H

8. Bending At 180 Degree No crack, purling and fraction

Application of Hot Rolled Steel Coil

As raw material for:

1. Container &Pipe Production

2. Carbon Structural Steel

3. Low Alloy Steel

4. High Quality Carbon Structural Steel

5. Atmospheric Corrosion Resistant Steel

6. Low Carbon Steel (Commericial Quality, Drawing Quality, Deep Drawing Quality)

Export Package of Hot Rolled Steel Coil

BULK SHIPMENT PACKED WITH STEEL BELT.

- Q: Hello,is it possible to divide an alloy in its own elements? I am particularly interested in Stainless Steel, which is made of Nickel, Chrome and Iron. Do you have an idea of where can I find some more information (blogs, reviews, sites or books)?Thanks for your help

- All you have to do is heat the alloy. Since an alloy is a physical mixture heating will be able to separate the different elements according to their melting point. All elements have their own unique melting point.

- Q: Ok, lately I've been taking to making things out of stainless steel chain mallie rings. The problem is that when i make a bracelet or something, the area around the fastener always looks pretty bad. I'm thinking to have a friend who also does chain mallie finish the weave all the way around. This would make it look good but make it impossible to remove.Are there any long term problems with stainless steel on skin? I know some metals will change the color of the skin or make the skin absorb some of the metal. Is this something to worry about with stainless steel?

- Stainless steel contains both nickel and chromium. These two alloys are responsible for most of contact dermatitis in people. Some of my co-workers making steel had such bad reactions to chromium that they had to quit their jobs. Their skin was always inflamed. People don't react to finished stainless steel the same way because the alloys are bonded tightly in the heat treating process. But if you are grinding it and getting the dust on your skin, you could get a contact dermatitis if you are sensitive. I don't think it would absorb into your blood stream or do any long term damage to your skin. If you do get a reaction, you would have to cease your exposure or in a worse case scenario risk getting a body wide reaction like my coworkers. I would not worry about any exposure making rings out of stainless steel. After all, stainless steel is used in sugical implants and most people are fine.

- Q: How are steel coils processed for painting or coating?

- Steel coils are processed for painting or coating through a series of steps. Firstly, the coils are cleaned to remove any dirt, oil, or scale using various methods like acid pickling or mechanical cleaning. Then, a primer or chemical treatment is applied to enhance the adhesion of the paint or coating. Next, the coils are dried to remove moisture and ensure proper adhesion. Finally, the paint or coating is applied to the coils using methods such as coil coating or electrostatic spraying, and then the coated coils are cured to achieve the desired finish and durability.

- Q: I just bought some cheap earrings from this beauty supply store but they said surgical steel So will they prevent my ears from bleeding / infection ?

- Surgical steel is a grade of steel often used in medical appliances like tweezers, forceps, etc. It's generally non-reactive and considered very safe. It doesn't contain any special properties against infection--you still have to observe basic hygiene and clean your piercings properly--but most people can wear surgical steel earrings without a problem. However, if you have a contact allergy to base metals like nickel, surgical steel may cause redness or irritation because of the metals used in it. If cheap rings or necklaces make your skin break out in a rash you should NOT wear surgical steel.

- Q: What are the different types of steel coil surface treatments for corrosion resistance?

- There are several different types of steel coil surface treatments that are used to enhance corrosion resistance. These treatments are applied to the surface of the steel coil to create a protective layer that prevents corrosion and extends the lifespan of the steel. Some of the common types of surface treatments for corrosion resistance include: 1. Galvanizing: This is one of the most popular and effective methods for protecting steel against corrosion. In this process, a layer of zinc is applied to the surface of the steel coil. The zinc acts as a sacrificial anode, corroding before the steel does, thus protecting it from rust and corrosion. 2. Chromate conversion coating: This treatment involves applying a chromate-based solution to the surface of the steel coil. The chromate forms a thin film on the steel, providing a protective barrier against corrosion. It also enhances the adhesion of paint or other coatings that may be applied later. 3. Phosphating: Phosphating is a process where a phosphate coating is applied to the steel coil. This coating provides excellent corrosion resistance by forming a chemical bond with the steel surface. It also improves the adhesion of subsequent coatings or paints. 4. Organic coatings: These coatings, such as paint or epoxy, are applied to the steel coil to create a barrier between the steel and the surrounding environment. They provide both corrosion resistance and aesthetic appeal. The choice of organic coating depends on the specific application and the desired level of corrosion protection. 5. Zinc-rich paint: Similar to galvanizing, zinc-rich paint contains a high concentration of zinc particles. When applied to the steel coil, the zinc particles provide sacrificial protection, preventing corrosion. This coating is often used in harsh environments or for steel coils that will be exposed to frequent moisture or saltwater. It is important to note that the choice of surface treatment depends on various factors such as the application, environment, budget, and required level of corrosion resistance. Consulting with a steel coil manufacturer or corrosion specialist is recommended to determine the most suitable treatment for a specific situation.

- Q: What is the cost of steel coils?

- The cost of steel coils can vary depending on factors such as size, quality, and market conditions. It is best to contact a supplier or check current market prices to get an accurate cost.

- Q: iam talking abt carbon steel of composition:-C=0.15wt% Mn=0.60wt% P=0.035wt% S=0.04wt% Cu=0.20 (min)wt%....

- The composition you mention is not a low carbon steel.The carbon and manganese content are high enough to mean that the crystal grain size will be small. A very large grain size is needed in steels for transformers,motors etc.The large grain size and lack of carbides in low silicon steels for magnetic purposes allows the easy movement of magnetic domain walls.Transformer steels typically have a carbon content of about 0.003% and 3.5%Si with the phosphorus and sulphur at a tenth of the levels you mention.The high Si content increases the electrical resistivity of the magnetic core and reduces the power loss from eddy currents(the core metal has voltages generated in it by the changing magnetic fields) and the power lost in eddy currents heats up a transformers core so it needs extra cooling;the loss is inversely proportional to the resistivity and 3.5%Si increases resistivity of iron by a very large amount.The presence of high silicon with ultra low carbon and manganese level allows the soft magnetic steels to be annealed at very high temperatures(850 to 1100deg C)without a phase change so that the crystals have 10,000 to 10,000,000 times the volume of the crystals in heat-treatable (Just)steel you mention.Fine for playing with and demonstrating electromagnetism but not as electrical engineering feedstuff.

- Q: What is the role of steel coils in the electrical industry?

- Steel coils play a crucial role in the electrical industry as they are used in the manufacturing of various electrical components and equipment. These coils are typically made of high-quality steel and are used in transformers, motors, generators, and other electrical devices. They provide structural support and act as a core for the electromagnetic field required for the functioning of these devices. Additionally, steel coils are also used in the production of magnetic cores, which are essential for efficient energy transfer and storage in electrical systems. Overall, steel coils are integral to the electrical industry, enabling the efficient and reliable operation of electrical equipment.

- Q: Can steel coils be used in the production of furniture?

- Yes, steel coils can be used in the production of furniture. Steel coils are often used as a raw material in the manufacturing of various types of furniture, such as chairs, tables, and bed frames. Steel coils provide strength, durability, and stability to the furniture, making it suitable for heavy-duty use. Additionally, steel coils can be shaped into different designs and sizes, allowing for versatility in furniture production. The coils can be transformed into various components, such as the frame or support structure of the furniture, providing a solid foundation. Moreover, the use of steel coils in furniture production can enhance the overall aesthetics of the furniture, as they can be finished in different colors and coatings to match the desired style. Overall, steel coils are a common and practical choice for furniture manufacturers due to their strength, durability, and design possibilities.

- Q: What are the common uses of galvanized steel coils?

- Galvanized steel coils are commonly used in a variety of applications such as construction, automotive manufacturing, HVAC systems, electrical appliances, and roofing. The galvanization process provides corrosion resistance, making these coils ideal for outdoor structures, metal frames, and components that are exposed to moisture or harsh weather conditions.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1958 |

| Annual Output Value | |

| Main Markets | Mid East Northern Europe North America Eastern Asia Africa Eastern Europe Southeast Asia Western Europe Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 80% |

| No.of Employees in Trade Department | 100People |

| Language Spoken: | English; Chinese; Korean |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Hot Rolled Steel Coil Best Quality from China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords