Best Quality For Hot Dip Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

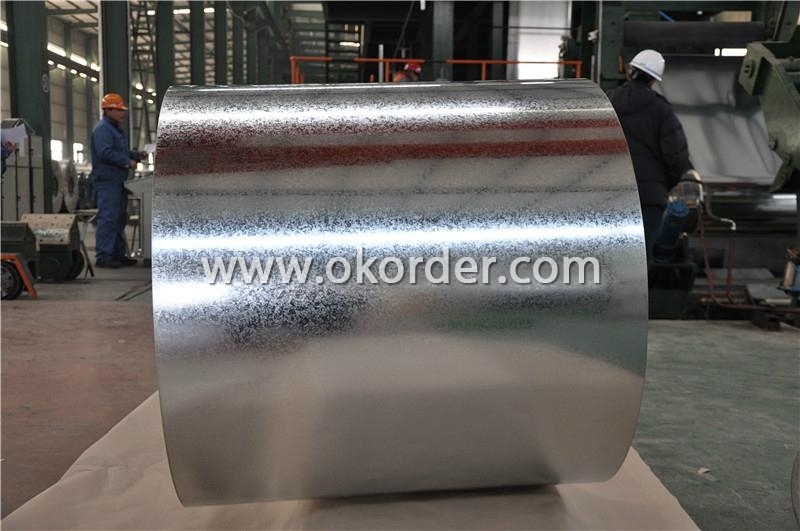

General Information of Hot Dip Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Specification of Hot Dip Galvanized Steel Coil

1. Thickness: 0.15-1.2mm

2. Width: 800mm-1250mm

3. Zinc Coating: 70-180g/m2

4. Internal Diameter: 508mm/610mm

5. Coil Weight: 3-12MT

6. Quality: commercial and structural quality

7. Surface Treatment: regular & minimum spangle, zero spangle, oiled & dry, chromated, non-skin pass ,skin pass

8. Standard: JIS G 3302, ASTM A 653M, EN 10327

9. Steel Grade: SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD

Technical Data of Hot Dip Galvanized Steel Coil

|

Chemical Composition |

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

|

Technical Data | |

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out-of-square |

not exceed 1% Flatness |

|

Bow |

15mmmax |

|

Edge Wave |

9mmmax |

|

Centre Buckle |

8mmmax |

|

Bending At 180 Degree |

No crack, purling and fraction |

Package of Hot Dip Galvanized Steel Coil

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips

Application of Hot Dip Galvanized Steel Coil

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

- Q: What are the different types of steel coil cutting methods?

- There are several different types of steel coil cutting methods, including shearing, slitting, and laser cutting. Shearing involves using a straight blade to cut through the coil, while slitting involves using circular blades to make multiple cuts. Laser cutting is a more precise method that uses a laser beam to cut through the coil. Each method has its advantages and is chosen based on the specific requirements of the project.

- Q: What are the different types of steel coil grades and specifications?

- There are several different types of steel coil grades and specifications, including hot rolled, cold rolled, galvanized, and stainless steel coils. Each type has its own unique properties and uses. Hot rolled coils are produced at high temperatures and are commonly used in construction and manufacturing applications. Cold rolled coils are produced at lower temperatures and have a smoother finish, making them suitable for applications that require a higher level of precision. Galvanized coils are coated with a layer of zinc to protect against corrosion, while stainless steel coils contain a high percentage of chromium for added durability and resistance to corrosion. Overall, the choice of steel coil grade and specification depends on the specific requirements of the project or application.

- Q: I felt that my nylon strings don't sound as good as steel ones. Is it okay that I replace them with steel ones, even if my guitar is classical? Thanks.

- I advise you not to as it will damage your guitar :) they do sound way better but that's what an acoustics for

- Q: How are steel coils inspected for coil set?

- Various methods and equipment are utilized to inspect steel coils for coil set. Coil set refers to the curvature or shape of the coil, which can affect its performance and usability in different applications. One way to inspect steel coils for coil set is through visual examination. Experienced operators or inspectors carefully assess the coils for any visible deformities or irregularities in their shape. This can be accomplished by unrolling a section of the coil and checking for signs of buckling, twisting, or unevenness. Visual inspection is a simple and cost-effective method to identify evident coil set issues. In addition to visual examination, more advanced techniques are employed to accurately measure and quantify coil set. One such technique involves using a straight edge or template. The straight edge is placed along the length or width of the unrolled portion of the coil, and any gaps or deviations from the straight edge indicate the presence of coil set. This method provides a more precise measurement of the extent and severity of the coil set. Another commonly used technique is the utilization of specialized tools like a non-contact laser measurement system. This system projects a line onto the surface of the coil using lasers and measures the distance between the line and the coil. Any variations in this distance indicate the presence of coil set. This method offers high accuracy and provides detailed data on the coil's shape and curvature. Other methods may involve the use of mechanical devices such as rollers or tensioners to unroll and measure the coil's shape. These devices exert controlled pressure on the coil to straighten it out, and any resistance or deviations encountered during the process serve as indications of coil set. Overall, the inspection of steel coils for coil set involves a combination of visual examination and precise measurement techniques. These methods aid in identifying and quantifying any deformities or irregularities in the coil's shape, enabling manufacturers and customers to make informed decisions about the usability and quality of the steel coils.

- Q: What are the common tests performed on steel coils?

- The common tests performed on steel coils include dimensional inspection, visual inspection, tensile testing, hardness testing, bend testing, and surface quality assessment. These tests ensure the quality, strength, and integrity of the steel coils before their use in various applications such as construction, automotive, and manufacturing.

- Q: How are defects in steel coils repaired?

- Defects in steel coils can be repaired through several methods depending on the type and extent of the defect. One common approach is known as welding repair, which involves using specialized welding techniques to fix the defect. This method is typically used for minor defects such as cracks or small holes in the coil. The damaged area is cleaned, prepped, and then welded using appropriate welding rods or wires to ensure a strong and durable repair. For more severe defects, such as large holes or significant damage to the coil, a patching technique may be employed. This involves cutting out the damaged section and replacing it with a new piece of steel. The patch is usually welded to the intact areas of the coil, ensuring a secure and seamless repair. In some cases, defects can also be addressed through grinding or sanding techniques. This is often used for surface defects like scratches or blemishes that do not compromise the structural integrity of the coil. Grinding or sanding the affected area smooths out the defect, improving the appearance and preventing further damage. It is worth noting that the repair method chosen depends on factors such as the specific defect, the material of the coil, and the intended application of the steel. The repair process may also involve additional steps such as heat treatment or surface finishing to restore the coil to its original condition. Overall, repairing defects in steel coils requires the expertise of skilled technicians and specialized equipment. It is crucial to address these defects promptly to prevent further damage and ensure the coil's performance and longevity.

- Q: How are steel coils tested for tensile strength?

- Steel coils are typically tested for tensile strength through a process called tension testing, where a sample of the coil is pulled until it breaks. This test measures the maximum amount of force the steel can withstand without breaking, helping to determine its tensile strength.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts by being formed into cylindrical shapes and then machined to create the desired dimensions and features of the shaft. The steel coil is typically cut to the required length and then undergoes a series of manufacturing processes, such as forging, heat treatment, and machining, to produce a strong and durable transmission shaft.

- Q: Is there much difference? Which is better? Are they equally safe? Is it just personal preference? Can you reccomend a good comfortable steel composite toe boot?

- steel toe boots are just that a piece of steel fitted over the toes, composite toe boots use other materials that are just as hard BUT they do not have the connectivity levels as steel. if you are working in a cold climate steel toes will freeze them toes right off, also electrical environments. my advice get a good pair of composite ones, and you get what you pay for, its worth the investment. more than you could ever imagine. proper foot support. helps legs cramps, back pain etc...

- Q: what is the porpose of preheating mild steel prior to welding

- :you could attempt welding with whats pronounced as a filler rod. you could weld with the a million/8 rod interior the welder stinger and by conserving the a million/sixteen rod in the different hand, upload it as you weld.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 1999 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Europe; Africa; Mid East; Southeast Asia |

| Company Certifications | ISO9001;ISO14001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai Port |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 50-80 |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality For Hot Dip Galvanized Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords