Hot Dip Galvanized Steel Coil-Regular Spangle

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Dip Galvanized Steel Coil-Regular Spangle

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Product Description Of Hot Dip Galvanized Steel Coil-Regular Spangle

|

Thickness |

0.13mm-0.7mm |

|

Width |

600mm-1250mm |

|

Zinc Coating |

30-200g/m2 |

|

Internal Diameter |

508mm/610mm |

|

Coil Weight |

3-12MT |

|

Quality |

commercial and structural quality |

|

Surface Treatment |

regular & minimum spangle, zero spangle, oiled & dry, chromated , non-skin pass , skin pass |

|

Standard |

JIS G 3302, ASTM A 653M, EN 10327 |

|

Steel Grade |

SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD |

Technical Data Of Hot Dip Galvanized Steel Coil-Regular Spangle

|

Chemical Composition |

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out-of-square |

not exceed 1% Flatness |

|

Bow |

15mmmax |

|

Edge Wave |

9mmmax |

|

Centre Buckle |

8mmmax |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Hot Dip Galvanized Steel Coil-Regular Spangle

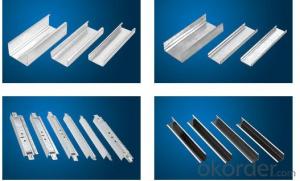

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

Packaging & Delivery Of Hot Dip Galvanized Steel Coil-Regular Spangle

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Production Flow Of Hot Dip Galvanized Steel Coil-Regular Spangle

Production flow of hot dip galvanized steel coil - zero spangle - forward - 30 - 200g/m2 include dual uncoiler, stitcher(welder), bridle, steering unit, entry accumulator, heating & soaking furnace, jet cooling section, ceramic zinc port, cooling tower, skin pass mill, tension leveller, chromating with dryer, exit accumulator and dual recoiler.

- Q: How are steel coils used in the production of agricultural systems?

- Steel coils are often used in the production of agricultural systems due to their durability and strength. These coils are typically used in the construction of machinery and equipment that are essential in agricultural operations. One common application of steel coils is in the manufacturing of farming machinery such as tractors, plows, and cultivators. These machines require sturdy components to withstand the demanding conditions of the agricultural environment. Steel coils are used to fabricate the frames, chassis, and other structural parts of these machines, providing the necessary strength and support. Steel coils are also used in the production of irrigation systems, which are crucial for efficient water management in agriculture. These coils are utilized in the construction of pipes, valves, and fittings, ensuring the durability and longevity of the irrigation system. Additionally, steel coils are used to manufacture storage tanks and silos, which are essential for storing and preserving agricultural products such as grains, seeds, and fertilizers. Furthermore, steel coils find application in the construction of greenhouses and agricultural buildings. The coils are used to fabricate the structural framework, providing stability and resistance against environmental factors. Steel coils are also used in the production of fencing and enclosures to protect crops and livestock from external threats. In summary, steel coils play a vital role in the production of agricultural systems by providing the necessary strength, durability, and stability required for farming machinery, irrigation systems, storage facilities, and agricultural structures. Their usage ensures that these systems can withstand the demanding conditions of the agricultural industry and contribute to efficient and sustainable farming practices.

- Q: How do steel coils contribute to fire resistance in buildings?

- Steel coils contribute to fire resistance in buildings primarily due to their material properties. Steel is a non-combustible material, meaning it does not burn or contribute to the spread of fire. It has a high melting point, which helps it retain its structural integrity even under high temperatures. Additionally, steel coils are often used as structural elements in building construction, providing strength and stability to the overall structure. This helps prevent the collapse of the building in case of a fire, providing occupants with more time to evacuate safely.

- Q: What is the diffrent Aluminized steel Type 1. stainless steel 409 430?

- Stainless steel 400 Series—ferritic and martensitic chromium alloys Type 409—cheapest type; used for automobile exhausts; ferritic (iron/chromium only) Type 430—decorative, e.g., for automotive trim; ferritic. Good formability, but with reduced temperature and corrosion resistance. Today, almost all bulk metal materials that are referred to loosely as aluminium, are actually alloys. For example, the common aluminium foils are alloys of 92% to 99% aluminium. Aluminized steel Type 1: 1xx.x series are minimum 99% aluminium

- Q: What is the difference between carbon steel and spring steel?? And which is the better one to make swords with??

- High Carbon Spring Steel

- Q: I want to purchase steel for construction purpose, What aspects should I keep in mind while deciding that which company should I contact for this?

- It has been a few years since I was in the business but I have found that some steel from some countries can be quite different from the standards steel made in the US. For instance, one in 5 of my Indian made cast iron fittings would break when tightening it down. This never happened with US fittings. Even though I could take it back and get a refund, the increased price of US made materials was worth the savings in time and trouble. On a job in Columbia, the 3 inch angle iron came to us in 4 different sizes, all around three inches but not quite. This is not to say that all foreign metal is bad. One RD project I headed up we found a foreign bearing steel to be far superior to anything we could get in the states.

- Q: it isn't a SIGG water bottle or any other brand, as it's from thingsengraved what I'm wondering is, is this just as good as a SIGG water bottle, or is there any difference?

- The problem with stainless steel water bottles is the steel takes even longer to decompose in our landfills then plastic its self. So it just adds to the waste. If you use steel be sure to recycle it when you are done using it. Another problem is the fact that we don't really make steel here anymore so you have to pollute the environment shipping steel here that the bottles are made from. It gets ship here on trucks, ships, and what not. Very big polluters!! You'd be better off just getting a reuseable bpa free plastic water bottle made in the usa. Or some of those expensive corn cups.

- Q: How are steel coils used in the production of metal roofing?

- Steel coils are used in the production of metal roofing by being fed through a series of machines that shape, cut, and coat the steel to create the final roofing product. The coils are uncoiled and flattened, then formed into the desired profile using roll forming machines. The formed sheets are then cut into specific lengths and coated with protective layers to enhance durability and corrosion resistance. These coated steel sheets are then packaged and shipped to construction sites for installation as metal roofing.

- Q: How do steel coils contribute to sustainability in construction?

- Steel coils contribute to sustainability in construction in several ways. Firstly, steel is a highly durable material that has a long lifespan. Steel coils are used in the construction of various structural components like beams, columns, and frames, ensuring the stability and strength of buildings. By using steel coils, the resulting structures require less maintenance and have a longer service life, reducing the need for frequent repairs or replacements. This durability enhances the sustainability of construction projects by reducing the overall environmental impact associated with material waste and energy consumption. Secondly, steel is a highly recyclable material. Steel coils can be easily recycled and reused in new construction projects. The recycling process of steel has a significantly lower environmental impact compared to the production of new steel. Recycling steel coils helps to conserve natural resources, reduce the extraction of raw materials, and minimize energy consumption in steel production. By incorporating recycled steel coils into construction projects, the demand for new steel production is reduced, resulting in lower greenhouse gas emissions and a smaller carbon footprint. Furthermore, steel is a material that can be prefabricated off-site. This means that steel coils can be manufactured in factories in a controlled environment, minimizing construction waste and improving construction efficiency. Prefabricating steel coils reduces the amount of material waste generated on-site and decreases the need for transportation of construction materials, thereby reducing air pollution and energy consumption during construction. Additionally, steel is known for its high strength-to-weight ratio, which allows for lighter and more efficient structures. By using steel coils, construction projects can optimize the use of materials, resulting in reduced material consumption and lessening the overall environmental impact. The lightweight nature of steel coils also facilitates easier transportation, reducing fuel consumption and associated emissions during delivery. In summary, steel coils contribute to sustainability in construction through their durability, recyclability, prefabrication capabilities, and high strength-to-weight ratio. By utilizing steel coils, construction projects can minimize waste, conserve resources, reduce energy consumption, and decrease the environmental impact, ultimately promoting a more sustainable built environment.

- Q: How are steel tape measures installed?

- That's the tape measure. There's a small card with no card in the middle of the screw! So it can't be retracted automatically! The solution is to wrap the open tape to the end!

- Q: Can one assume that stainless steel that can be hardened is magnetic?

- All steels are hardenable if you use the right process. Most stainless steels are magnetic but usually more weakly than mild steel.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | 33.03% Southeast Asia 33.03% South America 20.18% Africa 13.76% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port, China |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | Above 100 People |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low |

Send your message to us

Hot Dip Galvanized Steel Coil-Regular Spangle

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords