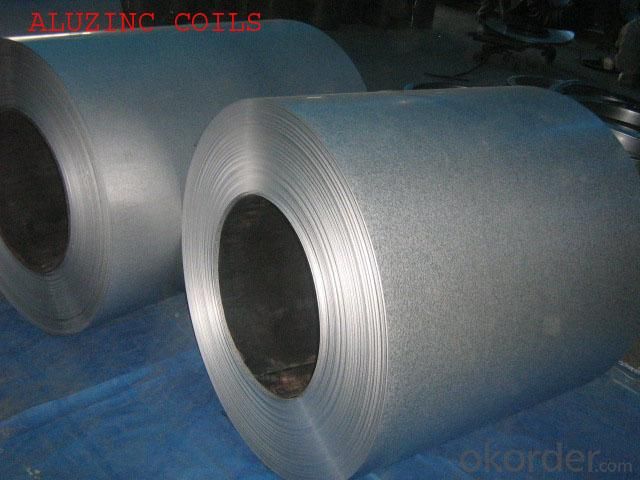

Best Quality for Aluzinc Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 100 Tons m.t.

- Supply Capability:

- 50000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Aluzinc Steel Coil

Hot-dip aluzinc steel sheet is substrated on cold rolled steel (CRC) in various strength and specification. Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

Specification:

1. Thickness: 0.25mm-4.0mm

2. Width: 900mm-1250mm

3. Alu-zinc Coating: 50-150g/m2

4. Internal Diameter: 508mm/610mm

5. Coil Weight: 4-8MT

6. Quality: commercial and structural quality

7. Surface Treatment: oiled & dry, chromated, anti-finger, non-skin pass/ skin pass

8. Standard: JIS G 3321, ASTM A792M, EN 10215

9. Steel Grade: SGCC, SGCD, CS,FS,SS,DX51D+Z DX52D+Z; S200GD, S220GD, S280GD, S350GD

Technical Data of Aluzinc Steel Coil

|

Chemical Composition |

C |

Si |

Mn |

P |

S |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

|

Technical Data | |

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out-of-square |

not exceed 1% Flatness |

|

Bow |

15mmmax |

|

Edge Wave |

9mmmax |

|

Centre Buckle |

8mmmax |

|

Bending At 180 Degree |

no crack, peeling and fraction |

Package of Aluzinc Steel Coil

Full wrapped with anti-damped paper inside, iron sheet wrapped outside, and bundled by iron strips

Application of Aluzinc Steel Coil

Aluzinc Steel can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making roofing tile, steel profiles for wall partition, T-bar, studs, fireproof door, air conditioning duct and home appliance.

- Q: So what's harder gold or steel

- steel. gold is pretty soft.

- Q: How are steel coils used in the production of building facades?

- Steel coils are used in the production of building facades as they provide a durable and versatile material for creating structural components such as panels, cladding, and roofing. The coils are processed and shaped into the desired form, allowing for easy customization and installation. The strength and resistance of steel make it an ideal choice for facades, ensuring long-lasting and aesthetically pleasing buildings.

- Q: Can steel coils be reused?

- Yes, steel coils can be reused. They are often recycled and repurposed for various applications in different industries.

- Q: What is the average width tolerance for steel coils?

- The average width tolerance for steel coils can vary depending on the specific industry and application. However, in general, the standard width tolerance for steel coils is typically around ±0.005 to ±0.020 inches.

- Q: How are steel coils processed for different levels of hardness?

- Steel coils can be processed to achieve different levels of hardness through a variety of methods. One common method is heat treatment, which involves heating the coils to a specific temperature and then rapidly cooling them to alter their microstructure and achieve the desired hardness. The process of heat treatment can include quenching, tempering, or annealing, depending on the desired hardness level. Quenching involves cooling the coils rapidly in a liquid medium such as water or oil to achieve a high hardness level. Tempering, on the other hand, involves reheating the coils to a lower temperature and then slowly cooling them to achieve a desired balance of hardness and toughness. Annealing is a process that involves heating the coils to a specific temperature and then slowly cooling them to relieve internal stresses and achieve a softer and more ductile material. Additionally, mechanical processes such as cold rolling or cold working can also be used to increase the hardness of steel coils. These processes involve subjecting the coils to compressive forces, which cause the material to deform and result in an increase in hardness. Overall, the processing of steel coils for different levels of hardness requires careful control of temperature, cooling rate, and mechanical forces to achieve the desired properties for specific applications.

- Q: What are the uses of galvanized steel coils?

- Galvanized steel coils are widely used in various industries for their durability and corrosion resistance. They are commonly used in construction for roofing, siding, and structural components. They are also used in the automotive industry for manufacturing parts such as body panels, chassis, and exhaust systems. Additionally, galvanized steel coils find applications in the manufacturing of appliances, agricultural equipment, and electrical enclosures.

- Q: How are steel coils stored in warehouses?

- Steel coils are typically stored in warehouses by stacking them horizontally on top of each other, often using specialized racks or shelves designed to support their weight. Coils are usually aligned in rows with adequate space between each stack to allow for easy access and movement of the coils. Additionally, some warehouses may use protective materials, such as wooden or plastic spacers, to prevent scratching or damage to the coils during storage.

- Q: I have a knife with AUS8 Stainless Steel. No idea what that means. I want to know some of the best stainless steels for knifes and all you can tell me about stainless steel would be great. I was browsing google and looking at grades and had no idea what all the numbers meant. Thanks!

- Ok so listen she already likes me what should I say

- Q: How are steel coils used in the production of containers?

- Steel coils are used in the production of containers as they are the primary material for manufacturing container bodies. These coils are shaped and welded into the desired container shape, providing strength and durability to the final product.

- Q: What are the common coil handling challenges?

- Some common coil handling challenges include the difficulty in safely lifting and moving heavy coils, ensuring proper alignment and positioning during handling, preventing damage to the coils or surrounding equipment, and efficiently managing coil storage and retrieval.

1. Manufacturer Overview

| Location | Wuxi, China |

| Year Established | 2002 |

| Annual Output Value | US$1 Million - US$2.5 Million |

| Main Markets | Mid East Northern Europe North America Eastern Asia Africa Eastern Europe Southeast Asia Western Europe Southern Europe |

| Company Certifications | ISO 9001;ISO 14000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 50 |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 600,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Best Quality for Aluzinc Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- T/T or L/C

- Min Order Qty:

- 100 Tons m.t.

- Supply Capability:

- 50000 Metric Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords