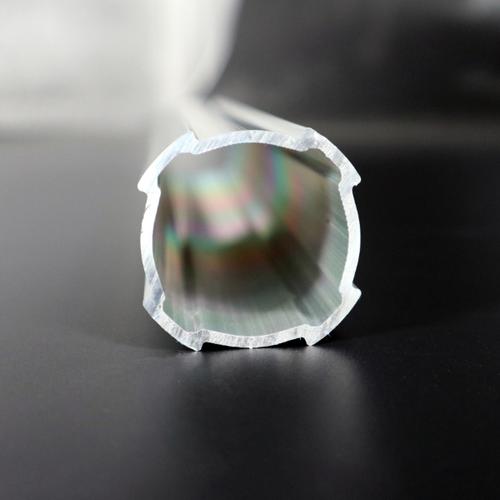

The third generation 43 series lean pipe aluminum alloy pipe

- Loading Port:

- DONGGUAN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Diameter 43mm standard size 1.7mm thickness anodized aluminum alloy tube for Karakuri system.

We are the manufacturer of aluminum tubes. Our products are sold directly from factories. With low prices and large shipments, we are the best choice for dealers.

43 series aluminum pipes are typically used in environments with higher requirements for load-bearing capacity. The aluminum tube with a thickness of 1.7mm can provide the user with sufficient bearing capacity. Compared with the traditional lean pipe, the aluminum pipe has less resin coating. Because the supporting connectors are also aluminum materials, it is easy to recycle when doing waste treatment. Moreover, the surface of the aluminum pipe is treated with acid resistant aluminum, and it can be kept beautiful for a long time without maintenance. At the same time, the aluminum tube surface is also coated to reduce oxidation and keep the factory clean.

Features

1. WJ-LEAN’s aluminum tube use international standard size, can be used in any international standard parts.

2. Easy assembly, only needs a screwdriver to complete the assembly. The material is environmentally friendly and recyclable.

3. Aluminum alloy surface is oxidized, the surface is smooth without burrs, and the overall system is beautiful and reasonable after assembly.

4.Product diversification design, DIY customized production, can meet the needs of different enterprises.

- Q: Can aluminum pipes be used for heat transfer applications?

- Yes, aluminum pipes can be used for heat transfer applications. Aluminum has good thermal conductivity, which allows it to efficiently transfer heat. Additionally, aluminum pipes are lightweight and corrosion-resistant, making them suitable for various heat transfer processes such as in heating systems, air conditioning units, and heat exchangers.

- Q: Can aluminum pipes be used for heat exchangers?

- Yes, aluminum pipes can be used for heat exchangers. Aluminum is widely used in the manufacturing of heat exchangers due to its excellent thermal conductivity and corrosion resistance properties. Additionally, aluminum pipes are lightweight, which makes them easier to handle and install in heat exchanger systems.

- Q: 502 glue to aluminum and plastic cement do

- But if your plastic is POM or HDPE HDPE, nothing will stick,Such as PPPEABSPCPSPVCPA, and these are QIS-3008L glue, the effect is very strong

- Q: How to repair the surface defects of aluminum pipe

- Third, the pipe is used to do it, the thickness of a pipe length measurement and recording, in general use will be selected according to the use of its wall thickness specifications and the length of the specifications, if found to have stiff head tubes should be timely marked when used to head to stiff it uses the slow speed, and high temperature.Fourth, after the completion of the expansion pipe, aluminum pipe to the appearance check to see whether the pipe surface defects, if flawed, allowing him to eliminate the timely elimination of defects if too much, not to be able to restore to enter the furnace re grinding clean.When the fifth tubes are heated, the thickness of the top three branch material shall be measured. After the expansion is completed, a measurement shall be carried out, and the expansion speed and temperature shall be adjusted according to the changes of these two measurements.The whole round repair of aluminum tubes is the most common repair in the industry, with the following methods for repairing the pits or flattening

- Q: Can aluminum pipes be used for scaffolding?

- Aluminum pipes are indeed suitable for scaffolding purposes. Due to their lightweight characteristic, high strength-to-weight ratio, and resistance to corrosion, aluminum is widely favored for scaffolding applications. These qualities render aluminum pipes perfect for the construction of scaffolding systems that are simple to handle, transport, and assemble. Moreover, aluminum scaffolding is renowned for its durability and long-lasting nature, making it an economically viable choice in the long term. Nevertheless, it is crucial to ensure that the aluminum pipes employed for scaffolding adhere to the required safety standards and regulations to safeguard the well-being of workers.

- Q: How to obtain hollow aluminum tubes such as drawings by rolling?

- Use mould to be able to do, do not know size, thickness, cannot decide what craft!

- Q: How is the seamless pipe or tube seam identification for enlighten heroes?

- Soak in a strong alkaline water for a while.

- Q: Do aluminum pipes require any special cleaning methods?

- Yes, aluminum pipes may require special cleaning methods. Aluminum can be prone to oxidation and discoloration, so it's important to avoid using abrasive cleaners or scrubbing brushes that could damage the surface. Instead, gentle cleaning solutions specifically designed for aluminum, along with soft cloths or sponges, should be used. Regular maintenance and drying after cleaning can help to prolong the lifespan and appearance of aluminum pipes.

- Q: Can aluminum pipes be used for swimming pool systems?

- Yes, aluminum pipes can be used for swimming pool systems. Aluminum is a lightweight and corrosion-resistant material, making it a suitable choice for pool systems. It is commonly used for piping systems in both residential and commercial swimming pools. Aluminum pipes are known for their durability and longevity, as they can withstand harsh weather conditions and chemical exposure. Additionally, aluminum pipes have excellent heat conductivity, ensuring efficient heat transfer for heating or cooling systems in pools. Overall, aluminum pipes are a reliable and cost-effective option for swimming pool systems.

- Q: Are aluminum pipes resistant to saltwater corrosion?

- Yes, aluminum pipes are generally resistant to saltwater corrosion. Aluminum is known for its excellent corrosion resistance, including resistance to saltwater. It forms a thin, transparent oxide layer on its surface when exposed to oxygen, which acts as a protective barrier against corrosion. This oxide layer helps to prevent the metal from reacting with saltwater, thus making aluminum pipes highly resistant to saltwater corrosion. However, it is important to note that prolonged exposure to saltwater can still lead to some degree of corrosion over time, but compared to other metals, aluminum is considered to be one of the most corrosion-resistant materials for saltwater applications.

Send your message to us

The third generation 43 series lean pipe aluminum alloy pipe

- Loading Port:

- DONGGUAN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches