Mild Steel Chequered Plate MS checker Plate Checkered Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM,GB,JIS

Technique:

Hot Rolled

Shape:

Round

Surface Treatment:

Coated,Oiled,Dry

Steel Grade:

Q195,Q215,Q235,SS400-SS490

Certification:

ISO,BV,CE

Thickness:

1.8mm-16mm

Width:

1000mm-1600mm

Length:

requirement

Net Weight:

23mt

Packaging:

Standard Export Packing

1.General Introduction

| Production Name | Hot Rolled Steel Chequered Sheet |

| Loading Port | Any Port in China |

| Thickness | 1.8mm-16mm |

| Width | 1000mm-1600mm |

| Coil Weight | 28 mt max |

| Material Grade | SS400\Q235\SAE1006\SAE1008 |

| Technique | Hot Rolled |

| Standard | GB \JIS\ASTM |

| Test | With Hydraulic Testing, Eddy Current , Infrared Test |

| Surface | 1) Bared |

| 2) Oiled | |

| Package | Standard Export Packing,Or at Customer’s Requirement |

| Sample | Common products, we can provide freely, for special production,we can depends on negotiation. |

| Payment | 100% L/C at sight, 30% T/T in advance |

| Delivery time | Within 10-25 days, according to quantity, asap save customer’s time |

| Certificate | ISO |

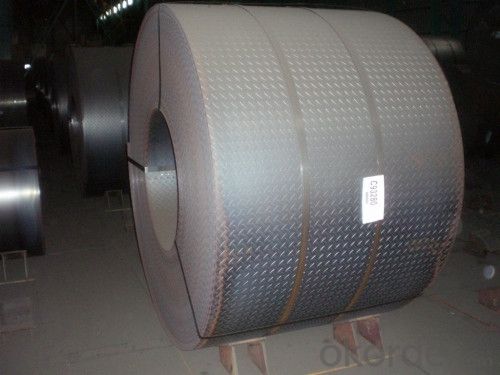

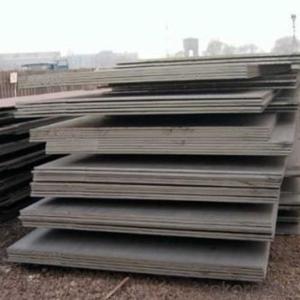

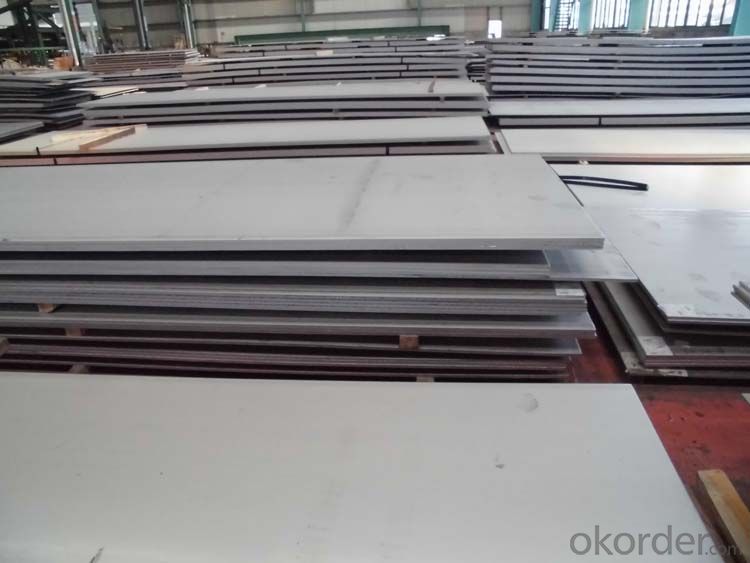

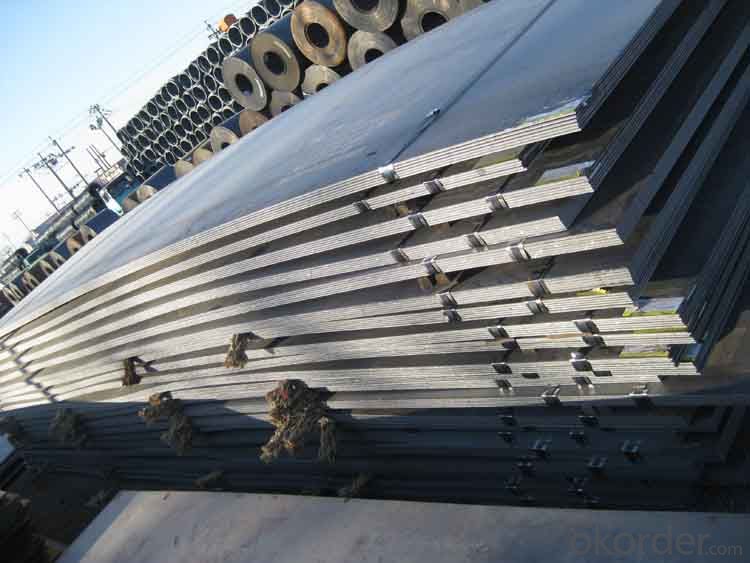

2.Product Photo

3.Our Service

- Q: How are steel coils used in the manufacturing of household appliances?

- Steel coils are commonly used in the manufacturing of household appliances as they serve as the primary material for constructing various components. These coils are shaped, cut, and processed to create parts such as frames, panels, and supports. Additionally, steel coils are used for creating durable and robust structures that provide stability and longevity to appliances like refrigerators, washing machines, and stoves.

- Q: How are steel coils unloaded from a truck?

- Steel coils are typically unloaded from a truck using a combination of heavy-duty forklifts, cranes, and specialized equipment. The coils are carefully lifted and positioned onto the ground or a designated storage area, ensuring proper safety measures and precautions are followed to prevent any damage or accidents during the unloading process.

- Q: How are steel coils used in the production of steel springs?

- Steel coils are used in the production of steel springs as they serve as the raw material for creating the spring's structure. The steel coils are typically shaped and cut into the desired length and diameter to form the spring's body. The coils are then heated and tempered to provide the necessary strength and flexibility required for the spring's function. Overall, steel coils are integral in the manufacturing process of steel springs, providing the base material from which springs are formed.

- Q: How are steel coils processed for different finishes?

- Various methods can be utilized to achieve different finishes on steel coils. One of the most commonly used is known as coil coating. This process involves several steps, including cleaning, priming, coating, and curing the steel coil to obtain the desired finish. To begin, any contaminants on the surface of the coil are removed, followed by the application of a primer to improve adhesion. Finally, a specific paint or coating material is applied to the coil. The coated coil is then subjected to high temperatures to ensure proper adhesion and durability. Another method for processing steel coils is galvanization. This technique involves coating the steel coil with a layer of zinc to protect it from corrosion. Galvanization can be achieved through hot-dip galvanization, where the coil is immersed in molten zinc, or electro-galvanization, where a thin layer of zinc is electroplated onto the coil. The resulting galvanized finish offers exceptional corrosion resistance and can be further processed for various aesthetic finishes. Furthermore, different surface treatments can be employed to achieve desired finishes on steel coils. These treatments may include pickling, which utilizes an acid solution to eliminate scale and impurities from the coil, or mechanical treatments like brushing or grinding to create a specific texture. Following these surface treatments, a protective coating or paint can be applied to enhance the appearance and durability of the coil. In conclusion, achieving various finishes on steel coils necessitates a combination of cleaning, coating, curing, and surface treatments. The selection of specific methods depends on the desired finish and the intended application of the steel coil.

- Q: How are steel coils used in the manufacturing of packaging materials?

- Steel coils are used in the manufacturing of packaging materials by being transformed into various forms, such as sheets or strips, that can be used for packaging products. These coils are often processed through cutting, shaping, and coating techniques to create packaging materials like cans, drums, or containers. The durability and strength of steel make it an excellent choice for packaging materials, ensuring the safe transportation and preservation of goods.

- Q: How are steel coils used in the manufacturing of automotive frames?

- Steel coils are used in the manufacturing of automotive frames by being shaped, cut, and welded into different sections to create the structural framework of the vehicle. These coils provide the necessary strength and durability required to support the weight of the vehicle and withstand various stresses, ensuring the safety and stability of the automotive frame.

- Q: How are steel coils tested for compliance with industry standards?

- Steel coils are tested for compliance with industry standards through a series of rigorous quality control measures. These tests are conducted to ensure that the coils meet the necessary specifications and are suitable for use in various applications. One of the primary tests performed on steel coils is the dimensional inspection. This involves measuring the thickness, width, and length of the coils to ensure they meet the specified tolerances. Any deviations from the required dimensions can indicate a manufacturing defect or potential issues during fabrication. Another critical test is the visual inspection, where trained inspectors carefully examine the coils for any surface defects such as scratches, dents, or cracks. These defects can affect the performance and durability of the steel coils, making it essential to identify and rectify them before they are supplied to customers. Furthermore, mechanical properties testing is conducted to assess the strength, elasticity, and toughness of the steel coils. This includes tests like tensile strength, yield strength, and elongation measurements. These tests help determine the suitability of the coils for specific applications and ensure they meet the required performance standards. Additionally, chemical composition analysis is performed to verify the elemental composition of the steel coils. This analysis is crucial as it ensures that the steel meets the required chemical requirements, including the presence of specific alloying elements. Deviations in composition can impact the overall quality and performance of the coils. Corrosion resistance testing is also important, especially for coils used in environments with high humidity or exposure to corrosive substances. Coils are subjected to salt spray or humidity chambers to simulate real-world conditions and evaluate their resistance to corrosion. Lastly, various non-destructive testing techniques, such as ultrasonic testing and magnetic particle inspection, are used to detect internal defects or discontinuities in the steel coils. These tests help identify any hidden flaws that may compromise the structural integrity of the coils. Overall, steel coils undergo a comprehensive range of tests to ensure compliance with industry standards. By conducting these tests, manufacturers can guarantee that the coils meet the required specifications, providing customers with high-quality products that meet their specific needs.

- Q: Can steel coils be coated with abrasion-resistant materials?

- Yes, steel coils can be coated with abrasion-resistant materials. These materials are specifically designed to provide a protective layer against wear and tear caused by friction, impact, or other forms of abrasion. Coating steel coils with abrasion-resistant materials helps to enhance their lifespan and durability, making them suitable for various applications that involve high levels of abrasion or mechanical stress.

- Q: Help please.What atoms are there in steel?Like water is equals to 1 Oxygen atom + 2 Hydrogen atoms.Thnx 4 d help.

- Steel is an alloy consisting mostly of iron, with a carbon content between 0.2 and 1.7 or 2.04% by weight (C:1000–10,8.67Fe), depending on grade. Steel is Fe(iron) and Carbon alloy. These are the atoms in certain ratio that make up steel. Its not a molecule but alloy.

- Q: How are steel coils used in the manufacturing of electrical enclosures?

- Steel coils are used in the manufacturing of electrical enclosures as they provide a durable and strong material that can be formed into various shapes and sizes. These coils are typically cut and shaped to create the main structure of the enclosure, providing a protective housing for electrical components. The steel coils are often coated or painted to enhance their resistance to corrosion and increase their longevity.

Send your message to us

Mild Steel Chequered Plate MS checker Plate Checkered Steel Plate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords