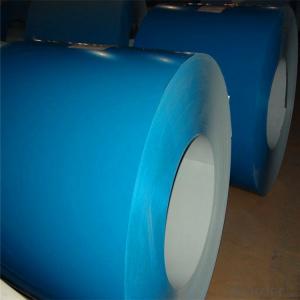

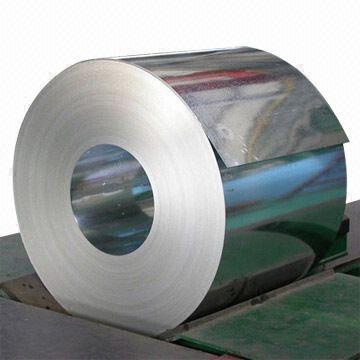

Hot dip galvanized steel coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Mt m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION:

Standard | JIS G 3302, ASTM A653, EN10327,10143,GB/T 2518 |

Grade | SPCC, DX51D+Z,CS Type A.B.C |

Zinc Coating | galvanized(GI) |

Zinc Weight | 40~140/m2 |

Thickness | 0.18mm~1.2mm |

Width | 762mm-1,250mm |

Coil weight | 3-20 tons |

Surface processing | Zero Spangle |

Coil Chemical Processing | Skin Pass,chromate,dry,oiled |

packing | waterproof paper and galvanized steel protection cover and steel strip packed Or as you request. |

Application | Construction, hardware, home appliances, interior decoration... |

Advantages | 1. Good experience producing and trading on PPGI/galvanized steel coil /steel sheet. With quality assurance and certification . 2.With technology strength and powerful. 3. Shortest delivery time . 4. authentication service and Sincere Caring Services. 5. We strive to be NO.1 of the same trade |

If you have any need of GI or PPGI Coil,please feel free to contact me.

- Q: How do steel coils contribute to fire resistance in buildings?

- Steel coils contribute to fire resistance in buildings primarily due to their material properties. Steel is a non-combustible material, meaning it does not burn or contribute to the spread of fire. It has a high melting point, which helps it retain its structural integrity even under high temperatures. Additionally, steel coils are often used as structural elements in building construction, providing strength and stability to the overall structure. This helps prevent the collapse of the building in case of a fire, providing occupants with more time to evacuate safely.

- Q: what is the difference between METAL and STEEL?

- A metal is a chemical element that is a good conductor of both electricity and heat and forms cations and ionic bonds with non-metals. Steel is a compound made from Iron and Carbon. Ratios of 0.2% and 2.1% by weight (information by wikipedia)

- Q: What are the quality standards for steel coil manufacturing?

- The quality standards for steel coil manufacturing include factors such as the grade and composition of the steel, dimensional accuracy, surface finish, mechanical properties, and adherence to industry-specific standards and specifications. These standards ensure that the steel coils meet the required strength, durability, and performance criteria for various applications such as construction, automotive, and manufacturing.

- Q: Hello, Do I make any damage to my stainless steel sink by cleaning it with clorox? Thank you!

- Bleach Stainless Steel Sink

- Q: What are the challenges in coil slitting for thin gauge materials?

- Some of the challenges in coil slitting for thin gauge materials include maintaining precise tolerances, avoiding material deformation or buckling during the slitting process, and ensuring consistent edge quality. Additionally, handling and feeding thin gauge materials can be more delicate, as they are more prone to damage or distortion. Proper tension control and alignment are crucial to prevent issues like edge wave or camber, which can affect the overall quality of the slit coils.

- Q: Does anyone know what is 12 gage Cold Rolled Steel meaning? Also, help me to describe it.Thank you so muck ~!Mark Lin

- Steel thickness is measured by gages. 16 gage is approximately 1/16th of an inch. The larger the number (say, 24), the thinner the steel. Steel is made from large metal bars (4'x12', about 8 thick) that pass through presses to get thinner and thinner. If the final stages of rolling are done with pressure and not heat, it is cold rolled. It often gets galvanized to prevent rusting. Hope this helps.

- Q: I have my grandpa's navy knife from ww2, a mk2 combat knife i think, and i was wondering what type of steel it is made of. I'm guessing it's a high carbon steel, i'd just like to know exactly what grade.

- 1095 Steel - Easy to sharpen, plain carbon steel used in knife making. Proven to be one of the most popular steels used in KA-BAR knives. Right from the OEM site. Worked for a company that started in 1859 as a safe manufacturer. The steel recipes have not changed much from WWII (when Elliot Ness was running the company) to now. Doubt the KA-BAR recipes has changed either.

- Q: How do steel coils perform in corrosive environments?

- Steel coils exhibit excellent performance in corrosive environments due to their inherent resistance to corrosion. This is primarily because steel, being composed of iron and various elements like carbon, produces a protective layer called a passive film. This passive film acts as a barrier between the steel surface and corrosive elements, effectively preventing direct contact and minimizing the risk of corrosion. Moreover, steel coils can be coated with different protective coatings to enhance their corrosion resistance. Coatings like zinc or epoxy provide an additional layer of protection, significantly prolonging the lifespan of steel coils in corrosive environments. However, it is important to acknowledge that the performance of steel coils in corrosive environments can still be influenced by factors such as the type of corrosive agent, duration of exposure, and presence of other contaminants. In highly aggressive environments, such as those with high humidity, exposure to saltwater, or acidic chemicals, the protective layers on steel coils might deteriorate over time, thereby increasing the potential for corrosion. To ensure optimal performance in corrosive environments, it is advisable to choose steel coils with corrosion-resistant properties, such as stainless steel or galvanized steel. Regular maintenance and inspections are also crucial to promptly detect any signs of corrosion and implement appropriate measures to prevent further damage. In conclusion, steel coils generally exhibit good resistance to corrosion in most environments, but the severity of the corrosive conditions can ultimately impact their performance.

- Q: I need to construct a table with three columns, which states the name of the steel, its compositions (e.g. Fe and C), and its special properties for a variety of different steel products.Help me please, a site with info would be great, explanations would be even better.

- Steel is an alloy consisting mostly of iron, with a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten.[1] Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another. Varying the amount of alloying elements and form of their presence in the steel (solute elements, precipitated phase) controls qualities such as the hardness, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but is also less ductile. H.

- Q: can u use stainless steel to make a coin? why or why not? answers based on facts plz.

- Stainless steel has been used by some countries to make coins, but it's not an ideal metal. When a coin is struck, a die comes down and strikes the blank with many tons of force (the blank is also sitting on top of another die--one has the image on the obverse (front) of the coin, while the other die has the image of the reverse of the coin). When the die strikes the blank, the force causes the metal in the blank to flow into the recesses of the die. The problem with stainless steel is that it doesn't want to flow into the die. To get an image, either the relief (how high the raised portion of the design will be) has to be very low, and the coin has to have a simple design, or they have to greatly increase the pressure of the strike. This slows the coining press down, and greatly shortens the life of the dies.

Send your message to us

Hot dip galvanized steel coil

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000 Mt m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords