Prepainted Galvanized Rolled Steel Coil-CS B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Sample Charge

1.Samples charge:According to your requirements . Sampling time:30days with minimum qty order.

2.Samples charge:Free for Existing Samples Sampling time:1day

Advantage

1. Low MOQ: We will do our best to make you satisfied.

2.Good Service : We treat clients as friend.

3.Good Quality :We have strict quality control system .Good reputation in the market.

4.Fast & Cheap Delivery: We have big discount from forwarder (Long Contract).

5.Supply Ability: 50000 ton monthly

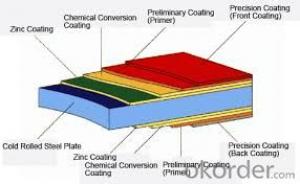

Specifications OfPrepainted Galvanized Steel

Thickness 0.20-1.2mm (BMT) Width 600-1250mm |

Zinc Coating 100-275g/m2 |

Color According to RAL color fan or as per request |

Internal Diameter 508mm or 610mm |

Coil Weight 3-6MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD,S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Applications OfPrepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

- Q: i have a question on a test and the questions before it are about blast furnace, wrought iron and cast iron...question 16 is..What is Steel?i dont really get what im being asked.. there could be many answers, what answer are they looking for?

- as steel is an alloy i thinkl they are looking for what elements it is made up of

- Q: Can steel coils be coated with anti-slip materials?

- Yes, steel coils can be coated with anti-slip materials.

- Q: how come when i put steel legs in lowest price in grand exchange no one buys them i got 101 steel legs in there and there at lowest price and they have been there for 3 days

- Becuase you should sell something else.

- Q: What are the common coil widths and thickness combinations available for steel coils?

- Common coil widths for steel coils range from 600mm to 2000mm, while common thickness combinations vary from 0.4mm to 3.0mm.

- Q: Why people prefer prefabricated buildings these days? Recently my friend has told me that he is going to owe a steel house so I was just thinking are these steel structures really durable and cheaper than concrete structures?

- It really depends upon the environment and the construction techniques used. Steel that is painted or coated will without maintenance eventually rust. I would expect this tendency to be exacerbated in a humid or shore environment. Heat may tend to cook a steel house and the structure does not add much thermal mass. Construction techniques tend to be fairly quick a part of the construction is essentially prefabricated. Work done in a factory will almost always be cheaper than work done in the field, all things being equal. Concrete can be fairly hi tech with lots of equipment or as seen in many parts of the world fairly low tech with lots of laborers. It is easy to change the characteristics of concrete depending upon how it is mixed, reinforced, and treated during the curing process. Because it is applied in a relatively fluid state it can flow around obstructions like bedrock and be formed up into interesting shapes. A concrete structure can be cooler as it provides thermal mass, and a heat sink. It's resulting rigidity may make it more subject to earthquakes than steel. We do really need to be smarter in constructing our homes to make them fit the land and not only the general environment but our particular micro environment.

- Q: How are steel coils used in the production of steel pipes?

- Steel coils are an essential component in the production of steel pipes. These coils serve as the raw material that is used to manufacture the pipes. The first step in the process involves unwinding the steel coil and feeding it into a machine called a slitter. The slitter cuts the coil into narrower strips of the desired width. This width is crucial as it determines the diameter of the steel pipes that will be produced. Once the steel coil has been slit into strips, the next step is to feed these strips into another machine called a forming mill. The forming mill gradually shapes the strips into a cylindrical shape by passing them through a series of rollers. These rollers apply pressure and bend the strips until they take on the form of a pipe. To ensure the durability and strength of the pipes, they undergo a welding process. The ends of the strip are heated and fused together using a high-frequency electric current, resulting in a continuous weld along the length of the pipe. This weld provides structural integrity and prevents any leakage or weak spots in the pipe. After the welding process, the pipes go through a sizing and shaping process. They are passed through additional rollers and gradually reshaped to achieve the desired dimensions, including the final outer diameter and wall thickness. Finally, the pipes are cut to the desired length and undergo various finishing processes such as straightening, testing, and coating. These finishing steps ensure that the pipes meet the required specifications and are ready for use in various applications, such as plumbing, construction, and oil and gas industries. In summary, steel coils are the starting point for the production of steel pipes. They are slit, formed, welded, sized, shaped, and finished to create durable and high-quality pipes that can be used in a wide range of industries.

- Q: what do they use to make stainless steel?and can stainless steel be melted again and again without losing it's Specifications

- This Site Might Help You. RE: What are the components of Stainless Steel? what do they use to make stainless steel? and can stainless steel be melted again and again without losing it's Specifications

- Q: I'm analysing horse stirrups and would like to know the disadvantages to stainless steel? - thanks

- Stainless Steel has more advantages than disadvantages. But u asked for disadvantages so they r as follows i've given common disadvantages more can be found on Google. Disadvantages of Stainless Steel: Stainless steel tends to scratch and dent. Food, grease and fingerprints show very clearly on stainless steel, making frequent wiping and cleaning a necessity. High initial cost Difficult to fabricate, or in other words, it is not as malleable as other metals, say iron, and hence if not fabricated properly, results in costly re-work. Difficult to weld High cost of polishing etc. i.e. adding finishing touches for the market. there are advantages more than disadvantages. But u asked for disadvantages that's why i have given only disadvantages of stainless steel Hope what u want u got.

- Q: Are steel coils susceptible to damage during storage or transportation?

- Yes, steel coils are susceptible to damage during storage or transportation. Steel coils are often heavy and can be prone to deformation, bending, and scratching if mishandled. Additionally, improper stacking or securing during transportation can lead to shifting or movement of the coils, which can cause damage. Furthermore, exposure to moisture, extreme temperatures, or corrosive substances can also affect the integrity of the steel coils. Therefore, it is crucial to handle, store, and transport steel coils carefully to minimize the risk of damage and ensure their quality and usability.

- Q: How are steel tape measures installed?

- That's the tape measure. There's a small card with no card in the middle of the screw! So it can't be retracted automatically! The solution is to wrap the open tape to the end!

Send your message to us

Prepainted Galvanized Rolled Steel Coil-CS B

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords