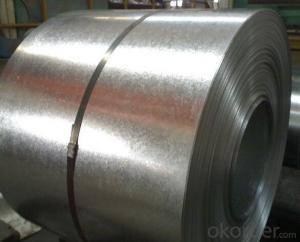

High Quality-Hot Dip Galvanized Steel Coil-Regular Spangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information Of Hot Dip Galvanized Steel Coil

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

|

Thickness 0.13-0.7mm (BMT) |

|

Width 600-1250mm |

|

Zinc Coating 30-200g/m2 |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 3-12MT |

|

Quality Commercial and structural quality |

|

Spangle Regular Spangle |

|

Surface Treatment Oiled/dry , Skin pass/non-skin pass ,Chromated/non-chromated |

|

Standard JIS G 3302, ASTM A 653M, EN 10327 |

|

Steel Grade SGCC, CS, FS, SS, LFQ, DX51D+Z , S280GD |

Chemical Composition Of Hot Dip Galvanized Steel Coil

|

C |

Si |

Mn |

P |

Si |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

0.006%-0.009% |

Technical Data Of Hot Dip Galvanized Steel Coil

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Out-of-square |

not exceed 1% Flatness |

|

Bow |

15mmmax |

|

Edge Wave |

9mmmax |

|

Centre Buckle |

8mmmax |

|

Bending At 180 Degree |

No crack, purling and fraction |

Application Of Hot Dip Galvanized Steel Coil

Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering

With GI as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

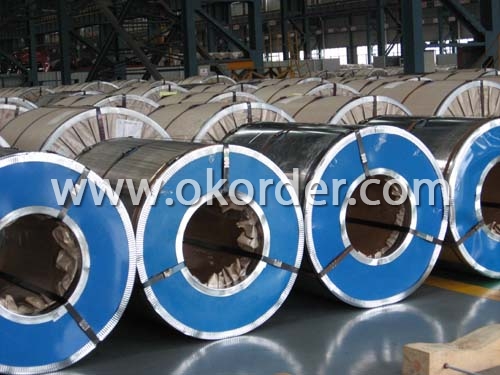

Packaging & Delivery Of Hot Dip Galvanized Steel Coil

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q: How are steel coils used in the manufacturing of engine mounts?

- Steel coils are used in the manufacturing of engine mounts as they provide strength, durability, and flexibility. These coils are typically used as the main component of the mount, providing the necessary support and stability for the engine. The steel coils are designed to absorb and dampen vibrations, ensuring smooth operation and minimizing the transfer of engine vibrations to the vehicle.

- Q: I'm planning to buy a pair of Doc Marten boots but I want some steel toed ones. I don't know if all of them are steel toed, or only some of them, or what?

- mine arent steel-toed....theyre upper leather certain types of boots maybe steel-toed in case the person wearing them is in construction...

- Q: What are the safety precautions for handling steel coils?

- When handling steel coils, it is important to follow certain safety precautions to prevent accidents and injuries. Some of these precautions include wearing appropriate personal protective equipment (PPE) such as gloves, safety glasses, and steel-toed boots to protect against cuts, impacts, and eye injuries. It is also essential to ensure proper training and knowledge of correct lifting techniques to avoid strains or back injuries. Additionally, using equipment like cranes or forklifts with appropriate capacity and stability is crucial for safe handling and storage of steel coils. Regular inspection and maintenance of equipment, as well as adhering to proper storage procedures, are also important safety measures to prevent incidents.

- Q: Is it just because brass is reloadable? But what makes it reloadable? What does brass bring to the equation that the steel cased ammo can't do?

- When 9mm was short I bought some steel Tula ammo, it was cheap and available. When at the range I was shooting it and it sounded different and felt different, way less kick. So I loaded up a mix of Tula and some Federal. Big difference between them. I also had failure to eject on the steel, then put brass in and did not have that problem. I do not buy cheap steel ammo anymore.

- Q: What are the different types of steel coil edge finishes?

- There are primarily three types of steel coil edge finishes: mill edge, sheared edge, and slit edge. The mill edge is the untreated edge of the steel coil, which is produced during the manufacturing process. The sheared edge is a straight cut made by a shear machine, resulting in a smooth and clean edge. The slit edge is created by cutting the coil along its width, typically using a slitting machine, and it may have a slightly rougher edge compared to the other two finishes.

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear slitting, loop slitting, and single-knife slitting.

- Q: What are the different types of steel coil packaging materials?

- There are several different types of steel coil packaging materials, including steel strapping, stretch film, plastic wrap, metal bands, and wooden crates. These materials help protect and secure steel coils during transportation and storage.

- Q: which is the most tough and durable steel type ??

- C'mon. Really? That's your question? How about some actual details like the application, is it going to be formed into a shape, do you need to weld it, what type of environment like corrosion and temperature is it going to be subject to? There are roughly 2,000 grades of steel and a couple hundred grades of stainless steel. Steels can be soft or they can be exceptionally hard. We need more info please.

- Q: Can steel coils be coated with heat-resistant materials?

- Yes, steel coils can be coated with heat-resistant materials.

- Q: I had a damascus steel katana made for me and was wondering if I could put gun blue on it to make the steel black and it still work right

- There okorder , the true Damascus is a region of spain, which is similar to getting swords made in Pakistan

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2010 |

| Annual Output Value | |

| Main Markets | 33.03% Southeast Asia 33.03% South America 20.18% Africa 13.76% Mid East |

| Company Certifications | ISO9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port, China |

| Export Percentage | 61% - 70% |

| No.of Employees in Trade Department | Above 100 People |

| Language Spoken: | Chinese, English |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Low |

Send your message to us

High Quality-Hot Dip Galvanized Steel Coil-Regular Spangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords