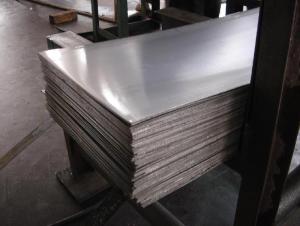

Low price aluzinc coated galvanized steel sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

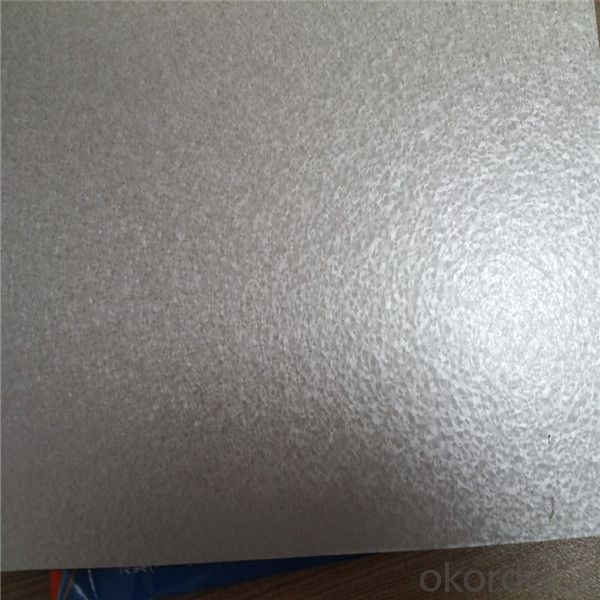

Galvalume should not be used on, in, or around concrete or mortar. Concrete and mortar are highly

alkaline environments. Bare Galvalume and painted Galvalume sheets suffer rapid corrosion when

in contact with mortar and concrete. Bare Galvanized and painted Galvanized perform better in this

type of environment.

The combination of zinc and aluminum in Galvalume enhances both the positive and negative effects

of aluminum. Galvalume has barrier corrosion resistance and heat resistance similar to aluminized

material and good bare edge galvanic protection and forming qualities like galvanized material. Consequently,

Galvalume and Galvalume Plus will resist rust, the elements and fire while providing a sturdy and protective covering.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

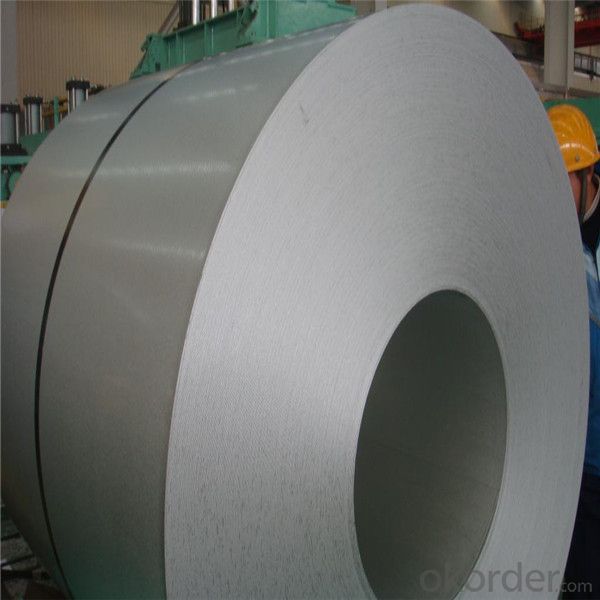

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

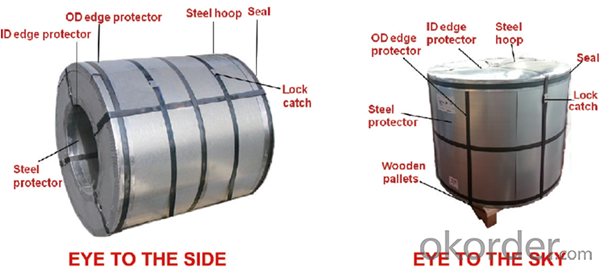

Packaging & Shipping

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: What is the process of galvanizing steel sheets?

- The process of galvanizing steel sheets involves immersing them in a bath of molten zinc. The sheets are first cleaned to remove any dirt or impurities. Then, they are dipped into a flux solution to remove any oxides and promote better adhesion of the zinc. Next, the sheets are fully immersed in the molten zinc bath, ensuring that all surfaces are coated. The zinc reacts with the steel, forming a protective layer that prevents corrosion. Finally, the sheets are cooled and inspected for quality before being ready for use.

- Q: Can steel sheets be used for fencing and gates?

- Yes, steel sheets can be used for fencing and gates. Steel sheets are strong, durable, and resistant to weathering, making them suitable for providing security and privacy. They can be easily installed and customized to fit various fencing and gate designs.

- Q: What is the typical composition of stainless steel sheets?

- Stainless steel sheets are primarily made up of iron, chromium, and nickel. These three elements are the main components that give stainless steel its unique properties. The amount of each element can vary depending on the specific grade of stainless steel being used, but generally, stainless steel sheets contain around 10-30% chromium and 8-20% nickel. Additionally, small amounts of other elements such as carbon, manganese, and molybdenum may be present to further enhance the strength, corrosion resistance, and other desired characteristics of the stainless steel. The composition of stainless steel sheets is carefully balanced to achieve the desired combination of strength, durability, and resistance to corrosion, making it a popular choice for various applications in industries such as construction, automotive, and manufacturing.

- Q: What is the impact resistance of galvanized steel sheets?

- Galvanized steel sheets have excellent impact resistance due to their strong and durable nature. The zinc coating on the steel provides an additional layer of protection, making it more resistant to dents and scratches. This makes galvanized steel sheets ideal for applications where impact resistance is important, such as construction, automotive, and industrial settings.

- Q: Can the steel sheets be bent or formed into different shapes?

- Steel sheets have the ability to be bent or shaped into various forms. Steel possesses exceptional malleability, enabling it to be effortlessly manipulated and molded without any risk of fracture. This advantageous characteristic facilitates a broad spectrum of applications requiring the bending or shaping of steel sheets, particularly in the construction sector, where beams, columns, and other structural elements necessitate specific configurations. Depending on the desired outcome and the steel's thickness, a range of techniques such as cold forming, hot forming, and press braking can be employed to accomplish the task of bending or shaping steel sheets.

- Q: Are steel sheets resistant to impact damage?

- Yes, steel sheets are highly resistant to impact damage due to their high strength and toughness. They can withstand significant force without fracturing or deforming, making them a reliable choice for applications where impact resistance is crucial.

- Q: Can steel sheets be used for automotive wheels?

- No, steel sheets are not typically used for automotive wheels. Instead, wheels are commonly made from aluminum alloy due to its lighter weight and better performance.

- Q: What are the different methods of protecting steel sheets from scratches?

- There are several methods of protecting steel sheets from scratches, including applying a protective coating such as paint or powder coating, using adhesive films or tapes, using protective sleeves or covers, and implementing proper handling and storage practices to minimize contact with abrasive surfaces.

- Q: Are the steel sheets suitable for architectural applications?

- Indeed, architectural applications can certainly make use of steel sheets. Steel, being a versatile material, presents numerous benefits for architectural purposes. It possesses strength, durability, and the ability to withstand harsh weather conditions, thus making it an excellent choice for various architectural elements like roofing, cladding, and facades. Furthermore, steel sheets provide architects with design flexibility, enabling the creation of unique and innovative structures. Moreover, steel is an environmentally sustainable material due to its recyclability and long lifespan, making it an eco-friendly option for architectural applications. All in all, steel sheets serve as a dependable and versatile choice for architects who desire to incorporate structural integrity, aesthetic allure, and sustainability into their designs.

- Q: What is the average cost of steel sheets compared to fiberglass?

- The average cost of steel sheets can vary compared to fiberglass sheets depending on a variety of factors. In general, fiberglass sheets tend to be less expensive than steel sheets. This is primarily because the raw materials used in steel sheet production are more costly, and the manufacturing process is more complex. Furthermore, steel sheets are renowned for their durability and strength, making them a popular choice for applications that require resilience and resistance to harsh weather conditions or impact. Conversely, fiberglass sheets are typically cheaper due to the lower cost of raw materials and the simpler manufacturing process involved. They are commonly employed in applications where weight and corrosion resistance are crucial factors, such as the construction of boats or aircraft. Nevertheless, it is important to acknowledge that market fluctuations, availability, and specific project requirements can also influence the cost comparison between steel and fiberglass sheets. Hence, it is advisable to obtain quotes from suppliers and compare prices to accurately determine the average cost within a given context.

Send your message to us

Low price aluzinc coated galvanized steel sheet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords