Reinforced PVC Waterproof Membrane 2mm Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

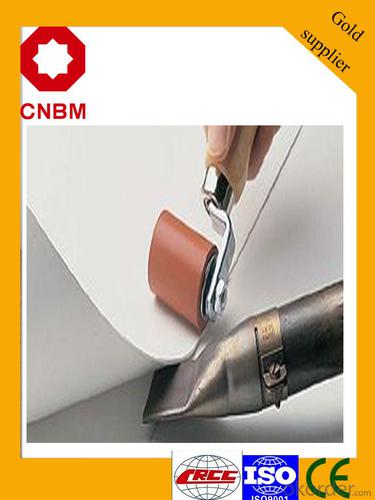

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used on rubber surfaces?

- Yes, a waterproofing membrane can be used on rubber surfaces.

- Q: Can a waterproofing membrane be used on storage tanks?

- Yes, a waterproofing membrane can be used on storage tanks. Waterproofing membranes are designed to create a barrier that prevents water or other liquids from penetrating through the surface they are applied to. When applied to storage tanks, these membranes can provide protection against leaks, corrosion, and damage caused by moisture. They are commonly used in various industries, including oil and gas, chemical, and water treatment, to ensure the integrity and longevity of storage tanks. Additionally, waterproofing membranes can be tailored to meet specific requirements, such as resistance to chemicals, UV exposure, or high temperatures, making them suitable for a wide range of storage tank applications.

- Q: Can waterproofing membranes be used on balconies?

- Yes, waterproofing membranes can be used on balconies. Waterproofing membranes are specifically designed to provide a protective barrier against water penetration, making them an ideal solution for balconies that are exposed to weather elements such as rain, snow, and moisture. These membranes are typically applied to the surface of the balcony to create a seamless, watertight seal, preventing water from seeping through and causing damage to the underlying structure. The use of waterproofing membranes on balconies helps to extend their lifespan, reduce maintenance costs, and ensure the overall durability and functionality of the balcony.

- Q: Can a waterproofing membrane be used in elevator pits or sump pits?

- Yes, a waterproofing membrane can be used in elevator pits or sump pits to prevent water infiltration and protect the structure from potential damage caused by moisture.

- Q: What is a waterproofing membrane?

- A waterproofing membrane is a thin layer or sheet made of materials like bitumen, rubber, or synthetic polymers that are applied to surfaces to prevent water penetration. It acts as a barrier, protecting structures such as roofs, basements, or foundations from water damage and leaks.

- Q: Can a waterproofing membrane be used on aerated concrete block surfaces?

- Indeed, the application of a waterproofing membrane is viable for aerated concrete block surfaces. The permeable nature of aerated concrete blocks renders them susceptible to water infiltration. Employing a waterproofing membrane on the blocks' surface can effectively impede water penetration and avoid harm. The membrane establishes a barrier that obstructs water passage while still enabling the blocks to respire and eliminate any trapped moisture. This facilitates the preservation and longevity of the aerated concrete block structures. However, it is imperative to ensure that the waterproofing membrane selected is explicitly engineered for aerated concrete blocks, as diverse materials necessitate distinct types of membranes for optimal performance.

- Q: Can waterproofing membranes be used on concrete block walls?

- Yes, waterproofing membranes can be used on concrete block walls. In fact, it is often recommended to use waterproofing membranes on concrete block walls to prevent water infiltration and moisture damage. Waterproofing membranes are designed to create a barrier against water and can be applied to the exterior or interior surface of the concrete block walls. These membranes provide an additional layer of protection, preventing moisture from seeping into the walls and causing issues such as mold growth, efflorescence, and deterioration of the concrete blocks. By using waterproofing membranes, you can ensure the longevity and durability of your concrete block walls.

- Q: Can waterproofing membranes be used on bridge decks?

- Bridge decks can benefit greatly from the application of waterproofing membranes. Due to the constant exposure to harsh weather conditions like rain, snow, and freeze-thaw cycles, the concrete and steel reinforcement of bridge decks can deteriorate. Waterproofing membranes are specifically designed to counter water infiltration and safeguard the bridge deck against damage caused by moisture. Typically composed of flexible materials like bitumen, PVC, or EPDM rubber, these membranes are directly applied to the surface of the bridge deck. Acting as a barrier, they prevent water from seeping into the concrete and causing corrosion of the reinforcement. They also help minimize crack formation and extend the lifespan of the bridge deck. Furthermore, the effectiveness and durability of waterproofing membranes can be enhanced by combining them with other protective coatings or systems. All in all, the utilization of waterproofing membranes on bridge decks is a widely employed and successful approach to ensure the long-term integrity and functionality of the structure.

- Q: Can a waterproofing membrane be used on roofs?

- Yes, a waterproofing membrane can be used on roofs. Waterproofing membranes are often applied to roofs to provide a protective barrier against water penetration and ensure the roof remains watertight.

- Q: Can a waterproofing membrane be installed in areas with high humidity?

- Installing a waterproofing membrane is possible in areas with high humidity. In fact, high humidity can contribute to the necessity of waterproofing due to the possibility of moisture accumulation and potential water damage. Regardless of the humidity levels, waterproofing membranes are designed to establish a barrier against water infiltration. Nonetheless, it is crucial to guarantee the correct installation and sealing of the membrane to prevent any moisture seepage. Moreover, in areas with high humidity, it might be essential to adopt additional measures like utilizing moisture barriers or dehumidifiers to provide further protection against potential water damage.

Send your message to us

Reinforced PVC Waterproof Membrane 2mm Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords