PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness

Product Description of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

1. Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2. Root resistant penetration, specially used on planting roofings.

3. Welding installation. Joints are solid and environment friendly, no pollution.

4. High tensile strength, good elongation and dimensional stability.

5. Good plasticity, easy and suitable for details installation.

6. Fireproof. Fire extinguished out of the ignition resource.

7. Surface is smooth, no fading and dirty resistant.

8. Width is over 2m. Construction wastage is small, more economical.

Classification of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, bridges , tunnel, water pools, shelter, grain depot, land filling and subwayProducts display.

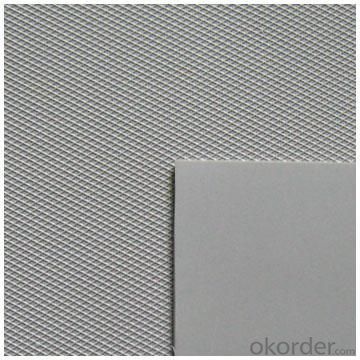

Images of PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used in permanent or long-term structures?

- Yes, a waterproofing membrane can be used in permanent or long-term structures. Waterproofing membranes are designed to provide durable and long-lasting protection against water intrusion. They are commonly used in various construction applications such as basements, roofs, foundations, and underground structures to prevent water damage and leakage. These membranes are engineered to withstand the test of time and can effectively extend the lifespan of a structure by ensuring its integrity and preventing moisture-related issues.

- Q: Can a waterproofing membrane be used on wood surfaces?

- Yes, a waterproofing membrane can be used on wood surfaces. Waterproofing membranes are designed to create a barrier that prevents water from penetrating the surface they are applied to. While they are commonly used on concrete or masonry surfaces, they can also be used on wood surfaces to protect them from moisture damage. Applying a waterproofing membrane on wood surfaces can help prevent water absorption, which can lead to rot, warping, or decay. It is important to choose a waterproofing membrane that is specifically designed for wood, as it will provide the necessary protection while allowing the wood to breathe and retain its natural characteristics.

- Q: Can a waterproofing membrane be used in boat decks or marinas?

- Yes, a waterproofing membrane can be used in boat decks or marinas. Boat decks and marinas are constantly exposed to water, making them prone to damage and deterioration over time. A waterproofing membrane can provide an effective solution to protect these surfaces from water intrusion, preventing issues such as rotting, warping, and mold growth. The membrane acts as a barrier, preventing water from seeping into the underlying structure and causing damage. It also helps to maintain the structural integrity of the boat deck or marina, prolonging its lifespan. Additionally, a waterproofing membrane can enhance the safety of these surfaces by reducing the risk of slip and fall accidents, as it can provide a slip-resistant surface. Overall, using a waterproofing membrane in boat decks or marinas is a wise choice to ensure their durability, longevity, and safety.

- Q: Can a waterproofing membrane be used in conjunction with paint or coatings?

- Using a waterproofing membrane alongside paint or coatings is a widely practiced technique in construction and renovation projects. This combination offers a dual-layer protection system, providing a barrier against moisture and preventing water infiltration. Additionally, the paint or coatings enhance the visual appeal and can offer extra defense against UV rays, weathering, and chemical exposure. To ensure the best outcome, it is crucial to confirm compatibility between the waterproofing membrane and the paint or coatings to avoid any negative reactions or loss of effectiveness. Seeking guidance from professionals or consulting the manufacturer's guidelines will help determine the most suitable combination and application process for your particular project.

- Q: Can a waterproofing membrane be used for a parking lot pavement?

- Indeed, a waterproofing membrane can be utilized to fortify the surface of a parking lot. Essentially, a waterproofing membrane is a substance that is applied to a surface to obstruct the entry of water. Generally employed in the realm of construction, it serves to safeguard walls, roofs, and foundations from water-related harm. Nevertheless, it can also be employed in parking lot pavements to heighten their sturdiness and longevity. Parking lots are constantly exposed to a multitude of meteorological conditions, including rainfall, snowfall, and icy conditions. Over time, these elements can infiltrate the pavement, resulting in deterioration, cracks, and potholes. By applying a waterproofing membrane to the pavement, the infiltration of water can be significantly minimized, effectively averting these issues from arising. The waterproofing membrane acts as a barricade, effectively barring water from permeating the pavement and infiltrating the underlying layers. This serves to keep the pavement dry, preventing problems associated with moisture, such as damage caused by freezing and thawing. Additionally, it offers protection to the pavement against substances like chemicals and oils, as well as any other spills that may occur on the surface. Employing a waterproofing membrane for a parking lot pavement can prolong its lifespan and reduce the need for frequent repairs and maintenance. Furthermore, it can enhance the overall appearance of the parking lot by preventing the formation of unsightly cracks and potholes. However, it is crucial to consider the specific requirements of the parking lot when selecting a waterproofing membrane. Factors such as the amount of traffic, the prevailing climate, and the type of pavement material must be taken into account to ensure the effectiveness and durability of the waterproofing system. In conclusion, a waterproofing membrane can serve as a suitable solution for augmenting the performance and longevity of a parking lot pavement. It can provide protection against water damage, prolong the lifespan of the pavement, and diminish the necessity for costly repairs.

- Q: Can a waterproofing membrane be used on roofs with rooftop gardens?

- Yes, a waterproofing membrane can be used on roofs with rooftop gardens. In fact, it is highly recommended to use a waterproofing membrane to protect the underlying structure from water damage. A rooftop garden adds additional weight and moisture to the roof, so a proper waterproofing system is essential to prevent leaks and ensure the longevity of the roof. The waterproofing membrane acts as a barrier against water infiltration and helps to keep the rooftop garden and the building below dry.

- Q: Can a waterproofing membrane be used on tunnels with railway systems?

- Tunnels with railway systems can indeed utilize waterproofing membranes. These membranes are widely employed in tunnel construction to prevent water ingress and safeguard the tunnel structure against deterioration. By effectively sealing the tunnel walls, ceilings, and floors, they successfully prevent water from seeping into the tunnel, thereby averting potential damage to the railway system or infrastructure. Specifically designed to withstand the high-pressure conditions and constant vibrations associated with railway operations, these membranes are typically composed of durable materials like PVC, HDPE, or modified bitumen. Such materials not only offer excellent waterproofing properties but also ensure long-term durability. Moreover, these membranes can be effortlessly installed during the tunnel's construction phase or retrofitted onto existing tunnels, causing minimal disruption to railway operations. In essence, the utilization of waterproofing membranes has proven to be a reliable and efficient technique for ensuring the structural integrity and longevity of tunnels with railway systems.

- Q: Can a waterproofing membrane be used in conjunction with insulation materials?

- Yes, a waterproofing membrane can be used in conjunction with insulation materials. The membrane acts as a barrier to prevent water infiltration, while insulation materials provide thermal resistance to control heat flow. This combination is commonly used in construction to ensure both waterproofing and insulation performance.

- Q: Does a waterproofing membrane require any specific surface preparation for tile installations?

- Yes, a waterproofing membrane typically requires specific surface preparation for tile installations. The surface needs to be clean, dry, and free of any dirt, dust, or debris. It is important to remove any loose or damaged tiles, repair any cracks or imperfections, and ensure the surface is smooth and level before applying the waterproofing membrane. This preparation ensures proper adhesion and a successful tile installation.

- Q: Can a waterproofing membrane be used in swimming pools?

- Yes, a waterproofing membrane can be used in swimming pools. In fact, it is a common practice to use waterproofing membranes in the construction or renovation of swimming pools to prevent water leakage. These membranes are specifically designed to create a barrier against water penetration, ensuring that the pool remains watertight and free from leaks. The membranes are typically made from durable materials such as PVC, EPDM, or polyurethane, which are resistant to water, chemicals, and UV rays. Additionally, the membranes are flexible and can easily adapt to the shape and contours of the pool, providing a seamless and long-lasting waterproofing solution.

Send your message to us

PVC Fiberglass Reinforced Waterproof Membrane with 1.5mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords