PVC Waterproof Membrane in 1.2mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproof Membrane in 1.2mm Thickness

Product Description of PVC Waterproof Membrane in 1.2mm Thickness:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproof Membrane in 1.2mm Thickness:

1. Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2. Root resistant penetration, specially used on planting roofings.

3. Welding installation. Joints are solid and environment friendly, no pollution.

4. High tensile strength, good elongation and dimensional stability.

5. Good plasticity, easy and suitable for details installation.

6. Fireproof. Fire extinguished out of the ignition resource.

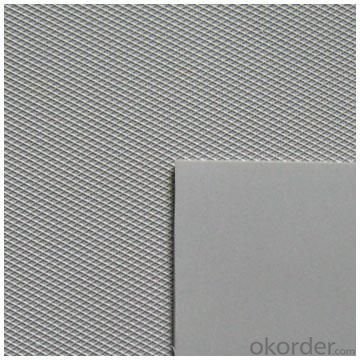

7. Surface is smooth, no fading and dirty resistant.

8. Width is over 2m. Construction wastage is small, more economical.

Classification of PVC Waterproof Membrane in 1.2mm Thickness:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproof Membrane in 1.2mm Thickness:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproof Membrane in 1.2mm Thickness:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproof Membrane in 1.2mm Thickness:

PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, bridges , tunnel, water pools, shelter, grain depot, land filling and subwayProducts display.

Images of PVC Waterproof Membrane in 1.2mm Thickness:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- Waterproofing membranes can vary in their resistance to chlorine exposure. Some membranes are specifically designed to be resistant to chlorine and are commonly used in applications where chlorine exposure is expected, such as pool decks or water treatment facilities. These membranes are typically made with materials like PVC or TPO that have inherent resistance to chlorine and can withstand prolonged exposure without significant degradation. However, it is important to note that not all waterproofing membranes are chlorine-resistant. Some membranes, particularly those made with materials like EPDM or bitumen, may not be as resistant to chlorine and may experience deterioration or damage when exposed to chlorine for extended periods. To ensure the longevity and effectiveness of a waterproofing membrane in a chlorine-rich environment, it is crucial to select a membrane that is specifically designed and tested for chlorine resistance. Consulting with a waterproofing professional or manufacturer can help determine the most suitable membrane for the specific chlorine exposure conditions.

- Q: Can a waterproofing membrane be used for a basement floor moisture barrier?

- Yes, a waterproofing membrane can be used as a basement floor moisture barrier. A waterproofing membrane is designed to prevent water from seeping through surfaces, making it an effective solution for keeping basements dry and free from moisture issues.

- Q: How does a waterproofing membrane handle differential settlement?

- The purpose of a waterproofing membrane is to prevent water infiltration and protect the underlying structure from moisture damage. However, the performance of the membrane can be affected when dealing with differential settlement. Differential settlement refers to uneven settling of the ground or building foundation, which can result in variations in height or level within the structure. This can cause stress and movement in the building, potentially impacting the waterproofing membrane. To address differential settlement, waterproofing membranes are designed to be flexible and capable of accommodating minor movements without compromising their effectiveness. They are often made from materials like modified bitumen, polyurethane, or rubberized asphalt, which have inherent elasticity and can stretch or contract to a certain degree. In cases of minor differential settlement within the membrane's tolerances, it can adjust and remain intact, maintaining its waterproofing capabilities. However, significant settlement or movement beyond the membrane's flexibility may cause cracks or tears, leading to potential water leakage. To minimize the impact of differential settlement, additional measures can be taken during membrane installation. This may involve incorporating stress-relieving elements like expansion joints or utilizing specialized installation techniques that allow for movement. These measures help distribute the stress caused by settlement and reduce strain on the waterproofing membrane. It is important to note that while waterproofing membranes can handle some level of differential settlement, they are not a solution for structural issues or significant settlement problems. In cases of severe settlement, it is crucial to address the underlying cause and potentially involve a structural engineer to determine appropriate remediation measures. In conclusion, a waterproofing membrane can accommodate minor movements caused by differential settlement through its flexibility. However, considering the severity of settlement and implementing additional measures during installation is crucial for ensuring the long-term effectiveness of the waterproofing system.

- Q: Can a waterproofing membrane be used for loading docks and warehouses?

- Yes, a waterproofing membrane can be used for loading docks and warehouses. Waterproofing membranes are commonly used in these areas to prevent water infiltration and protect the building's structure and contents from moisture damage. They create a watertight barrier that helps to maintain a dry and safe environment for the storage and movement of goods.

- Q: Does a waterproofing membrane prevent mold and mildew growth?

- Yes, a waterproofing membrane can help prevent mold and mildew growth. Mold and mildew thrive in damp and moist environments, and a waterproofing membrane helps to create a barrier that prevents water from seeping into the surfaces it is applied to. By keeping moisture out, it reduces the conditions that promote mold and mildew growth. However, it is important to note that while a waterproofing membrane can be effective in preventing mold and mildew, it does not guarantee complete protection. Proper ventilation and regular maintenance are also essential in preventing mold and mildew growth.

- Q: Are waterproofing membranes suitable for residential applications?

- Yes, waterproofing membranes are suitable for residential applications. They can effectively prevent water intrusion and protect homes from moisture damage, making them an ideal solution for basements, foundations, roofs, and other areas prone to water leakage.

- Q: Can waterproofing membranes be used on underground tunnels?

- Yes, waterproofing membranes can be used on underground tunnels. Waterproofing membranes are specially designed to provide a barrier against water penetration and are commonly used in various construction applications, including underground structures such as tunnels. These membranes are typically made of materials like bitumen, asphalt, or synthetic rubber, which have excellent waterproofing properties. When applied to the tunnel walls and floors, waterproofing membranes create a protective layer that prevents water from seeping into the tunnel. This is particularly important in underground tunnels as they are susceptible to water intrusion from surrounding soil or groundwater. By using waterproofing membranes, the integrity and durability of the tunnel structure are maintained, reducing the risk of water damage, corrosion, and deterioration. Furthermore, waterproofing membranes can also offer additional benefits such as providing resistance against chemical attacks, preventing the growth of mold and mildew, and improving the overall insulation of the tunnel. These membranes can be applied during the construction phase of the tunnel or as a retrofit solution to existing tunnels. It is important to note that the selection of the appropriate waterproofing membrane should be based on factors such as the type of tunnel, the expected water pressure, and the overall design requirements. Consulting with a professional engineer or waterproofing specialist is highly recommended to ensure the selection and installation of the most suitable waterproofing membrane for underground tunnels.

- Q: How does a waterproofing membrane handle exposure to chemicals or solvents?

- Protection against water and moisture is the primary purpose of a waterproofing membrane. However, the membrane's ability to resist chemicals or solvents varies based on the type used. Various waterproofing membranes are available on the market, each possessing its own unique properties and capabilities. Certain membranes are specifically designed to withstand exposure to chemicals or solvents. These membranes are typically constructed using materials like PVC, TPO, or CPE. These materials offer exceptional chemical resistance, making them highly effective in environments where contact with chemicals or solvents is anticipated. In contrast, some waterproofing membranes may not possess the same level of resistance to chemicals or solvents. For example, membranes composed of bitumen or asphalt may experience degradation or damage when exposed to certain chemicals or solvents. In such cases, additional protective measures may be necessary, such as applying a chemical-resistant coating or implementing a secondary barrier to prevent direct contact between the membrane and the chemicals or solvents. When selecting a waterproofing membrane, it is crucial to consider the specific requirements of the project and the potential exposure to chemicals or solvents. Seeking guidance from a professional waterproofing contractor or manufacturer can help determine the most suitable membrane for the intended application. Regular inspections, maintenance, and proper cleaning of the membrane are also essential to ensure its longevity and performance when faced with chemicals or solvents.

- Q: Can a waterproofing membrane be applied to vertical surfaces?

- Yes, a waterproofing membrane can be applied to vertical surfaces. Waterproofing membranes are designed to create a barrier against water penetration and can be applied to various surfaces, including vertical ones such as walls or pillars.

- Q: Can a waterproofing membrane be used in geotechnical applications?

- Indeed, geotechnical applications can make effective use of waterproofing membranes. These membranes are commonly employed to safeguard structures against water infiltration and are applied to various surfaces such as roofs, basements, and foundations. In geotechnical applications, these membranes serve the purpose of preventing water from seeping into the soil, thus averting erosion and stabilizing slopes. They can be positioned either horizontally or vertically to establish a barrier that hinders water penetration, which proves particularly advantageous in retaining walls, embankments, and dams. Furthermore, waterproofing membranes can be used to regulate water flow and enhance drainage in geotechnical projects. All in all, incorporating a waterproofing membrane into geotechnical applications can significantly enhance the longevity and performance of structures while effectively safeguarding them against water-related issues.

Send your message to us

PVC Waterproof Membrane in 1.2mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords