Textured Used In Underground PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

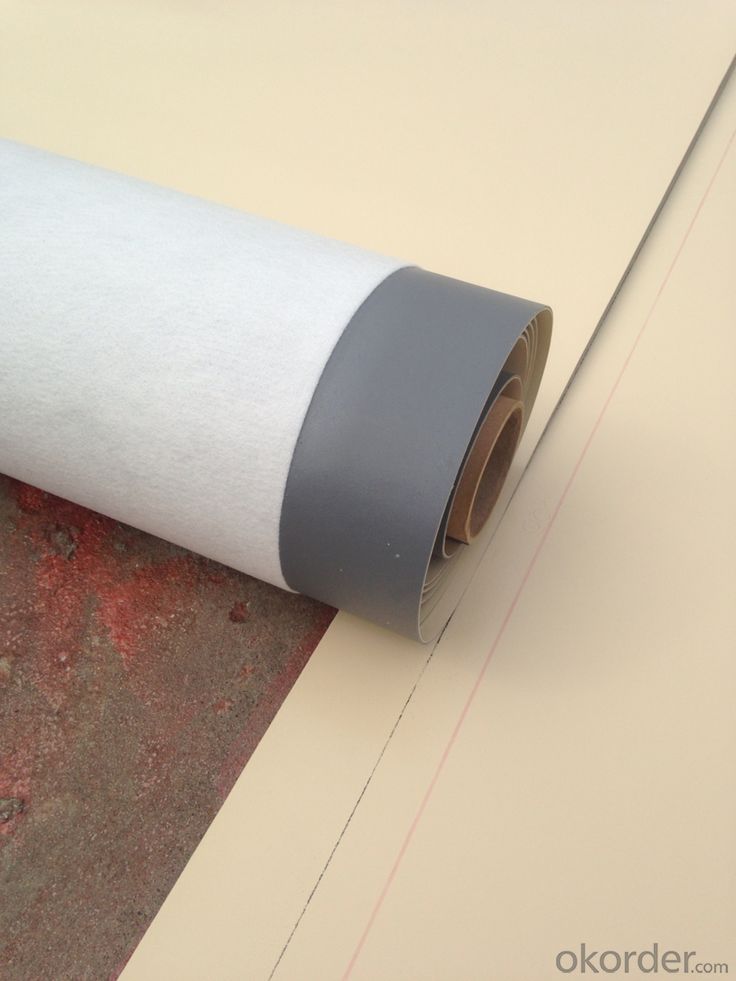

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

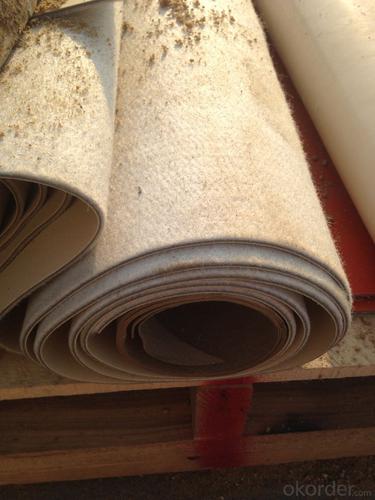

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used on plastic surfaces?

- Yes, a waterproofing membrane can be used on plastic surfaces.

- Q: Can a waterproofing membrane be used in basements and foundations?

- Basements and foundations can benefit greatly from the use of a waterproofing membrane. It is highly recommended to apply this protective layer in order to safeguard against water infiltration and moisture-related problems. Typically, the membrane is applied on the outer side of the foundation walls and basement floors, effectively creating a barrier that prevents water from permeating through the concrete. This essential measure ensures that the basement and foundation remain dry, minimizing the risk of water damage, mold growth, and structural complications. There are several types of waterproofing membranes available, including bituminous, rubberized asphalt, and liquid-applied options. This variety allows for flexibility when selecting the most suitable option according to the specific project requirements. Ultimately, installing a waterproofing membrane is a reliable means of improving the overall resilience and longevity of basements and foundations.

- Q: What is the preferred level of waterproofing?

- 3, roof 3 waterproof: Application: general building; Waterproof layer of reasonable use of life: 10 years; Waterproof layer selection of materials: should choose three asphalt four oil asphalt waterproofing membrane, polymer modified asphalt waterproofing membrane, synthetic polymer waterproofing membrane, metal sheet, polymer modified asphalt waterproof coating, synthetic polymer waterproof coating , Fine stone concrete, flat tile, felt tile and other materials;

- Q: Can a waterproofing membrane be used in coastal areas?

- Indeed, the utilization of a waterproofing membrane is viable in coastal regions. Given their susceptibility to copious amounts of moisture and water exposure, it becomes imperative to implement efficient waterproofing measures. By appropriately installing and upkeeping a waterproofing membrane, one can establish a protective barrier, effectively thwarting water infiltration and averting structural damage while ensuring their longevity. Nevertheless, it is crucial to opt for a membrane specifically tailored for coastal environments as they exhibit heightened resistance to saltwater and possess superior durability to withstand the harsh coastal conditions. Moreover, routine inspection and maintenance are imperative to guarantee the continued efficacy of the waterproofing membrane in coastal areas.

- Q: Can a waterproofing membrane be used on tunnels with railway systems?

- Yes, a waterproofing membrane can be used on tunnels with railway systems. The membrane helps to prevent water ingress and moisture damage to the tunnel structure, ensuring the safety and longevity of the railway system.

- Q: Does a waterproofing membrane prevent water vapor transmission?

- Yes, a waterproofing membrane is designed to prevent both liquid water and water vapor from penetrating through a surface. It acts as a barrier that blocks the movement of moisture, including water vapor, thus preventing water intrusion and potential damage to the underlying structure. Waterproofing membranes are commonly used in various applications such as roofs, basements, and bathrooms to ensure the integrity and durability of the building envelope.

- Q: Can a waterproofing membrane be used for zoos or aquariums?

- Yes, a waterproofing membrane can be used for zoos or aquariums. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can be an effective solution for preventing water damage and leakage in these types of environments. They can be applied to various surfaces, such as concrete or steel, to create a watertight seal and prevent water from seeping into the structure or habitat. Waterproofing membranes are often used in aquariums to ensure that the tanks remain water-tight and do not leak, which is crucial for the well-being of the aquatic animals. Similarly, in zoos, waterproofing membranes can be used in animal enclosures or exhibit areas to prevent water damage to the structures and maintain a safe and healthy environment for the animals. Additionally, the membranes can also protect against potential chemical spills, as they are often resistant to various chemicals and can withstand harsh conditions. Overall, waterproofing membranes are a suitable option for zoos or aquariums as they provide an effective solution for maintaining the integrity of the structures and habitats, preventing water damage, and ensuring the safety and well-being of the animals.

- Q: Can a waterproofing membrane be used for an industrial facility floor?

- Yes, a waterproofing membrane can be used for an industrial facility floor. Waterproofing membranes are commonly used in industrial settings to protect floors from water damage and to prevent moisture from seeping into the concrete or substrate. These membranes are designed to create a seamless and impermeable barrier that can withstand heavy foot traffic, industrial equipment, and chemical spills. They can also provide additional benefits such as resistance to mold and mildew growth, increased durability, and easier maintenance. However, it is important to choose a waterproofing membrane that is specifically designed for industrial applications and to follow the manufacturer's instructions for proper installation and maintenance.

- Q: Can a waterproofing membrane be used for plant rooms or mechanical spaces?

- Yes, a waterproofing membrane can be used for plant rooms or mechanical spaces. Plant rooms and mechanical spaces are areas where equipment, machinery, or systems are installed, and they often contain pipes, tanks, or other components that require protection from water damage. A waterproofing membrane is a durable, flexible, and watertight barrier that can be applied to surfaces such as walls, floors, or ceilings to prevent water infiltration. By using a waterproofing membrane in plant rooms or mechanical spaces, you can ensure the longevity and functionality of the equipment and systems by protecting them from water leaks or moisture damage. Additionally, a waterproofing membrane can also provide a vapor barrier, preventing the buildup of condensation or humidity, which can be detrimental to sensitive equipment.

- Q: Are there any environmental considerations when using a waterproofing membrane?

- When using a waterproofing membrane, there are several environmental factors to consider. One major concern is the possibility of harmful chemicals or materials being used during production. Some membranes may contain toxic substances like volatile organic compounds (VOCs) or heavy metals, which can negatively impact both human health and the environment. Another consideration is how to properly dispose of the membrane at the end of its lifespan. Many waterproofing membranes are not biodegradable and can contribute to landfill waste. Incorrect disposal methods can lead to environmental pollution and harm ecosystems. Furthermore, the production of waterproofing membranes often involves energy-intensive processes and the extraction of non-renewable resources. This can result in greenhouse gas emissions and the depletion of natural resources. To address these environmental concerns, it is crucial to select waterproofing membranes that have been made using eco-friendly materials and processes. Look for products labeled as low VOC or free from hazardous substances. Additionally, consider using recyclable membranes or those made from recycled materials to decrease waste generation. Proper disposal of the membrane at the end of its life cycle is also vital, and options such as recycling or repurposing should be explored. In conclusion, it is essential to take the environmental impact of waterproofing membranes into account and choose products and practices that minimize harm to the environment and promote sustainability.

Send your message to us

Textured Used In Underground PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords