PVC Polyester Reinforced Waterproof Membrane with 1.0mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Polyester Reinforced Waterproof Membrane with 1.0mm Thickness

Product Description of PVC Polyester Reinforced Waterproof Membrane with 1.0mm Thickness:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Polyester Reinforced Waterproof Membrane with 1.0mm Thickness:

1. Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2. Root resistant penetration, specially used on planting roofings.

3. Welding installation. Joints are solid and environment friendly, no pollution.

4. High tensile strength, good elongation and dimensional stability.

5. Good plasticity, easy and suitable for details installation.

6. Fireproof. Fire extinguished out of the ignition resource.

7. Surface is smooth, no fading and dirty resistant.

8. Width is over 2m. Construction wastage is small, more economical.

Classification of PVC Polyester Reinforced Waterproof Membrane with 1.0mm Thickness:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Polyester Reinforced Waterproof Membrane with 1.0mm Thickness:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Polyester Reinforced Waterproof Membrane with 1.0mm Thickness:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Polyester Reinforced Waterproof Membrane with 1.0mm Thickness:

PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, bridges , tunnel, water pools, shelter, grain depot, land filling and subwayProducts display.

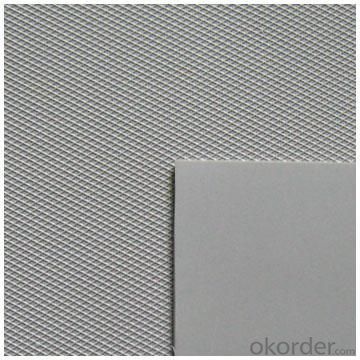

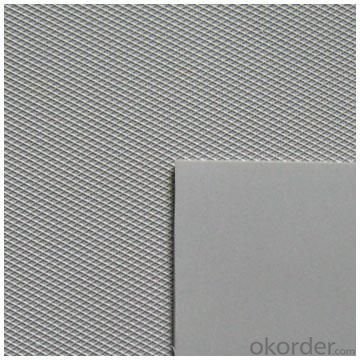

Images of PVC Polyester Reinforced Waterproof Membrane with 1.0mm Thickness:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for HVAC systems?

- Using a waterproofing membrane directly for HVAC systems is not possible. Waterproofing membranes are designed to prevent water from penetrating surfaces like roofs, foundations, or walls. They are typically made of materials such as bitumen, rubber, or polyurethane and are intended to protect against water damage. In contrast, HVAC systems are responsible for regulating temperature, humidity, and air quality in a building. They consist of various components like ductwork, air handlers, and condensing units that are specially designed for conditioning and circulating air. While there may be some overlap in terms of protecting certain HVAC system components from moisture, such as ductwork insulation, relying solely on a waterproofing membrane is insufficient and inappropriate for HVAC systems. HVAC systems require specialized materials and equipment that are tailored to meet the specific needs and requirements of air conditioning and ventilation. Therefore, it is crucial to use the appropriate materials and equipment specifically designed for HVAC systems to ensure their efficient and effective operation.

- Q: Does a waterproofing membrane require any specific safety precautions during installation?

- Specific safety precautions are necessary when installing a waterproofing membrane. Consider the following key precautions: 1. Personal Protective Equipment (PPE): Installers must wear appropriate PPE, such as gloves, safety glasses, and protective clothing, to avoid skin contact with the membrane and potential chemical hazards. 2. Adequate Ventilation: Ensure that the installation area has proper ventilation to prevent the accumulation of fumes or vapors. If working in a confined space, use ventilation systems to eliminate any potentially harmful gases or odors. 3. Hazardous Chemicals: Some waterproofing membranes contain hazardous chemicals or solvents. Installers should carefully read and adhere to the manufacturer's instructions for handling and using these products. Proper storage, handling, and disposal of chemicals are crucial to prevent accidents or environmental contamination. 4. Slips and Falls: The surface can become slippery during installation, particularly when applying the membrane on wet surfaces. Installers should take precautions to maintain stability and utilize safety equipment like harnesses or guardrails when working at heights to prevent falls. 5. Heat Hazards: Proper installation of certain waterproofing membranes requires the use of heat. Installers should exercise caution when working with heat sources such as torches or heat guns to prevent burns or fire hazards. Keep fire extinguishers readily available and ensure that personnel receive adequate training on fire safety protocols. 6. Electrical Safety: Waterproofing membranes might be installed in areas where electrical systems are present. Installers should exercise caution when working near live electrical wires or outlets and adhere to proper electrical safety procedures to prevent electric shocks or fires. It is crucial for installers to undergo comprehensive training and diligently follow all safety guidelines provided by the manufacturer. This will help minimize the risk of accidents, injuries, or property damage during the installation process.

- Q: Can a waterproofing membrane be used for a roof deck?

- Certainly! A roof deck can indeed utilize a waterproofing membrane. Its purpose is to safeguard against water infiltration, rendering it a perfect resolution for roof decks that face rain, snow, and other atmospheric conditions. Typically, the membrane is administered atop the roof deck surface, constructing an impermeable and long-lasting barrier that thwarts water from permeating the underlying structure. Consequently, this elongates the lifespan of the roof deck while shielding it from possible water harm. Furthermore, certain waterproofing membranes present supplementary advantages, including UV resistance and thermal insulation, thereby amplifying their appropriateness for roof deck usage.

- Q: Can a waterproofing membrane be installed on any surface?

- A waterproofing membrane can generally be installed on a variety of surfaces, but there are some factors to consider. The suitability of the surface depends on its condition, composition, and the type of waterproofing membrane being used. Typically, waterproofing membranes are designed to adhere to various substrates such as concrete, wood, metal, and masonry. They can be applied to surfaces like roofs, foundations, basements, bathrooms, and balconies. However, it is crucial to ensure that the surface is clean, dry, and free from any contaminants, such as dirt, debris, or loose materials, before installing the membrane. Furthermore, certain surfaces may require additional preparatory work or primers to enhance adhesion and ensure a long-lasting waterproofing solution. For example, rough or uneven surfaces might need to be leveled or smoothed out before the membrane can be applied. It is also important to consider the specific requirements of the waterproofing system being used. Different membranes have different application methods and compatibility with different surfaces. Some membranes may be more suitable for horizontal surfaces like flat roofs, while others may be better suited for vertical surfaces such as walls or foundations. Ultimately, it is recommended to consult with a professional waterproofing contractor or refer to the manufacturer's guidelines to determine the compatibility of the waterproofing membrane with a specific surface and to ensure proper installation for optimal performance and longevity.

- Q: Does a waterproofing membrane require any special considerations for installation in high-humidity areas?

- Yes, a waterproofing membrane does require special considerations for installation in high-humidity areas. High humidity can increase the moisture levels in the air, which can affect the performance and effectiveness of the membrane if not properly addressed during installation. Here are some important considerations: 1. Moisture control: In high-humidity areas, it is crucial to control the moisture levels before installing the waterproofing membrane. The surface should be thoroughly dried, and any existing moisture issues or leaks should be addressed and fixed before installation. 2. Vapor barriers: Installing a vapor barrier beneath the waterproofing membrane can help prevent moisture from penetrating through the membrane. This is especially important in high-humidity areas where the moisture levels in the air are consistently high. 3. Proper ventilation: Adequate ventilation is key in high-humidity areas to reduce moisture buildup. Make sure there is proper airflow and ventilation systems in place to promote drying and prevent condensation, which can compromise the integrity of the waterproofing membrane. 4. Waterproofing membrane selection: Not all waterproofing membranes are suitable for high-humidity areas. It is important to choose a membrane that is specifically designed and recommended for such environments. Look for membranes with high moisture resistance and durability. 5. Professional installation: Proper installation is essential for the long-term performance of the waterproofing membrane. In high-humidity areas, it is recommended to hire professional contractors who have experience working in similar conditions and can ensure proper installation techniques are followed. By considering these factors, you can ensure that the waterproofing membrane performs effectively and provides reliable protection against moisture in high-humidity areas.

- Q: Can waterproofing membranes be used on elevator pits?

- Indeed, elevator pits can benefit from the utilization of waterproofing membranes. Given their underground location, elevator pits are susceptible to water infiltration, which can lead to detrimental water damage and leaks. To combat these moisture-related issues, waterproofing membranes offer a highly effective solution by preventing water penetration and safeguarding elevator pits. Typically composed of rubber, polyurethane, or bitumen, these membranes are specifically designed to create a watertight barrier. Through their application on the walls and floor of the elevator pit, they form a seamless and durable protective layer. As a result, this membrane system ensures the maintenance of a dry pit, consequently preventing water damage to the elevator components and ensuring the safe and reliable operation of the elevator.

- Q: Are there any specific installation techniques for corners and edges when using a waterproofing membrane?

- Using a waterproofing membrane requires specific techniques for installing corners and edges. These techniques are necessary to guarantee proper sealing and protection against water infiltration. For corners, it is advisable to utilize corner flashings or preformed corner pieces that are specially designed for waterproofing applications. These flashings or pieces are typically made of flexible materials like rubber or PVC. They should be placed over the membrane, securely fastened to the substrate, and overlapped with the membrane to create a continuous barrier against water. When dealing with edges, installing edge flashings is crucial to prevent water from seeping beneath the membrane. Edge flashings are installed along the perimeter of the waterproofing membrane and are usually made of the same material as the membrane itself. They should be firmly sealed and securely fastened to the substrate to ensure a tight and dependable seal. In addition, it is important to properly overlap the membrane at corners and edges to create a seamless and continuous barrier against water. It is necessary to carefully follow the manufacturer's instructions to determine the correct width and method of overlap. In general, a minimum overlap of at least 2 inches is recommended for corners and edges. Overall, the specific installation techniques for corners and edges when using a waterproofing membrane involve the use of corner and edge flashings, proper sealing and fastening, and correct overlap of the membrane. By adhering to these techniques, a reliable and effective waterproofing system can be achieved.

- Q: Can a waterproofing membrane be used for a shower enclosure?

- Yes, a waterproofing membrane can be used for a shower enclosure. These membranes are specifically designed to prevent water from seeping through the walls and floor, ensuring a watertight seal. They are commonly used in construction and renovation projects to protect areas prone to moisture, such as bathrooms and showers.

- Q: Can a waterproofing membrane be used for dams?

- Yes, a waterproofing membrane can be used for dams. These membranes are designed to prevent water leakage by creating a barrier that is resistant to water penetration. They can be applied to the surface of the dam to ensure its integrity and prevent seepage of water through the structure.

- Q: SBS waterproofing membrane sub-class I and II when to use what level to use a secondary level

- For the PE film (aluminum), color sand, shale, fine sand and other four categories; width: 1000mm, 10m long, 15m two specifications; thickness: polyester felt coil 3mm, 4mm, 5mm; fiberglass membrane 3mm, 4mm; glass fiber reinforced polyester felt 5mm Scope: Widely used in industrial and civil construction of the roof, basement, bathroom and other waterproofing works and roof gardens, roads, bridges, tunnels, parking lots, swimming pools and other projects waterproof and moisture. Deformation of the larger project recommended the use of excellent extension of the polyester tire products, other buildings should choose a relatively economical glass fiber products. So look at the temperature and then choose.

Send your message to us

PVC Polyester Reinforced Waterproof Membrane with 1.0mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords