Heat-resistant Polyvinyl Chloride PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

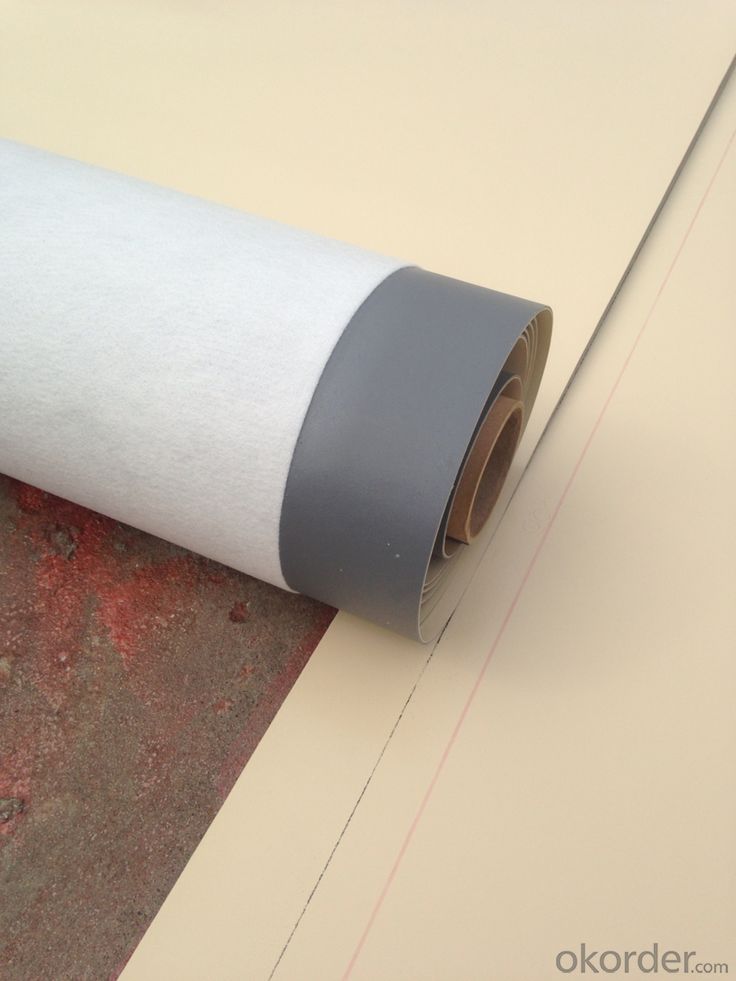

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used on exterior walls?

- Yes, a waterproofing membrane can be used on exterior walls. A waterproofing membrane is designed to provide a barrier against water infiltration and can be applied to various surfaces, including exterior walls. It helps prevent water from seeping into the walls and causing damage such as mold, mildew, or structural issues. By creating a protective layer, a waterproofing membrane can enhance the durability and longevity of the exterior walls, especially in areas prone to heavy rainfall or high humidity. However, it is important to choose the appropriate type of waterproofing membrane that is suitable for exterior wall applications and follow the manufacturer's instructions for proper installation to ensure optimal effectiveness.

- Q: Can a waterproofing membrane be used on roofs with slope?

- Yes, a waterproofing membrane can be used on roofs with slope. In fact, it is often recommended to use a waterproofing membrane on sloped roofs to prevent water infiltration and to ensure proper drainage. The membrane is installed beneath the roofing material and acts as a barrier against moisture, helping to protect the roof and the underlying structure from water damage.

- Q: Can a waterproofing membrane be removed or replaced if necessary?

- Yes, a waterproofing membrane can be removed or replaced if necessary. Over time, waterproofing membranes can deteriorate or be damaged, leading to leaks or moisture penetration. In such cases, it is necessary to remove the existing membrane and replace it with a new one to ensure proper waterproofing. The process of removal and replacement involves carefully stripping off the old membrane, cleaning the surface, and applying a new membrane system. It is important to consult with a professional waterproofing contractor who can assess the condition of the existing membrane and provide appropriate recommendations for removal and replacement.

- Q: Does a waterproofing membrane prevent water damage to building materials?

- Yes, a waterproofing membrane is designed to create a barrier that prevents water from seeping into building materials, thus effectively preventing water damage.

- Q: Are there any specific safety precautions to consider when installing a waterproofing membrane?

- Yes, there are several safety precautions to consider when installing a waterproofing membrane. Firstly, it is important to wear proper personal protective equipment (PPE) such as gloves, goggles, and a respirator to protect against potential chemical exposure and inhalation of fumes. Additionally, ensure adequate ventilation in the work area to prevent the buildup of fumes. It is also crucial to follow the manufacturer's instructions and guidelines for installation to minimize the risk of accidents or improper application. Lastly, be cautious of potential hazards such as slippery surfaces, sharp edges, or working at heights, and take necessary precautions to prevent falls or injuries.

- Q: Can a waterproofing membrane be used on retaining walls?

- Yes, a waterproofing membrane can be used on retaining walls. Retaining walls are often exposed to moisture and hydrostatic pressure, which can lead to water infiltration and deterioration of the structure. Applying a waterproofing membrane on the retaining wall can help prevent water penetration, protect the wall from moisture-related damage, and prolong its lifespan. The membrane acts as a barrier, preventing water from seeping into the wall and causing potential issues such as efflorescence, cracks, or erosion. It is important to choose a waterproofing membrane that is specifically designed for below-grade applications and is capable of withstanding the pressure exerted by the retained soil. Additionally, proper installation techniques and appropriate drainage systems should be considered to ensure the effectiveness of the waterproofing membrane on retaining walls.

- Q: Can a waterproofing membrane be used on tunnels with railway systems?

- Yes, a waterproofing membrane can be used on tunnels with railway systems. Waterproofing membranes are commonly used in tunnel construction to prevent water ingress and protect the tunnel structure from deterioration. These membranes can effectively seal the tunnel walls, ceilings, and floors, preventing water from seeping into the tunnel and potentially causing damage to the railway system or infrastructure. Waterproofing membranes are specifically designed to withstand the high-pressure conditions and constant vibrations associated with railway operations. They are typically made of durable materials such as PVC, HDPE, or modified bitumen, which provide excellent waterproofing properties and long-term durability. Furthermore, these membranes can be installed during the construction phase of the tunnel or retrofitted onto existing tunnels with minimal disruption to the railway operations. Overall, the use of waterproofing membranes is a proven and effective method to ensure the structural integrity and longevity of tunnels with railway systems.

- Q: Can a waterproofing membrane be used on precast cement board surfaces?

- Yes, a waterproofing membrane can be used on precast cement board surfaces. Precast cement board surfaces are commonly used in construction, especially for exterior applications. These surfaces are not inherently waterproof, so applying a waterproofing membrane can provide an extra layer of protection against water infiltration. A waterproofing membrane is a thin layer of material that is applied to the surface of the cement board. It forms a barrier that prevents water from penetrating the board and reaching the underlying structure. This is particularly important for areas that are exposed to moisture, such as bathrooms, kitchens, and outdoor installations. There are different types of waterproofing membranes available, including liquid-applied membranes and sheet membranes. Liquid-applied membranes are typically rolled or sprayed onto the surface, while sheet membranes are applied like a sticker. Both types provide an effective waterproofing solution for precast cement board surfaces. When choosing a waterproofing membrane for precast cement board surfaces, it is essential to consider the specific requirements and conditions of the project. Factors such as the level of water exposure, climate, and intended use of the surface should be taken into account. It is also important to follow the manufacturer's instructions for application, as proper installation is crucial for the effectiveness of the membrane. In conclusion, a waterproofing membrane can be used on precast cement board surfaces to provide additional protection against water infiltration. It is a wise choice for areas that are exposed to moisture and can help prolong the lifespan of the cement board and prevent damage to the underlying structure.

- Q: Can a waterproofing membrane be used in historic buildings?

- Indeed, it is possible to utilize a waterproofing membrane in historic buildings. Given their age and construction materials, historic buildings frequently encounter challenges associated with moisture infiltration and water damage. To address this, waterproofing membranes offer a prevalent solution that prevents water seepage and safeguards the structural integrity of the building. Nonetheless, it is crucial to select a waterproofing membrane that is compatible with the materials and construction methods employed in the historic building to guarantee its preservation and adherence to historical authenticity. Moreover, any waterproofing work undertaken on a historic building should be carried out by professionals possessing expertise in historic preservation. This ensures proper installation and minimizes any adverse impact on the building's historical value.

- Q: Can a waterproofing membrane be used on precast wood surfaces?

- Yes, a waterproofing membrane can be used on precast wood surfaces. Waterproofing membranes are commonly used to protect various types of surfaces, including wood, from water damage. These membranes are designed to create a barrier that prevents water from seeping through and causing structural issues or rot in the wood. By applying a waterproofing membrane to precast wood surfaces, you can effectively protect the wood from moisture and prolong its lifespan. However, it is important to ensure that the membrane is compatible with wood and follow the manufacturer's guidelines for application to achieve the best results.

Send your message to us

Heat-resistant Polyvinyl Chloride PVC Waterproof Membrane

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords