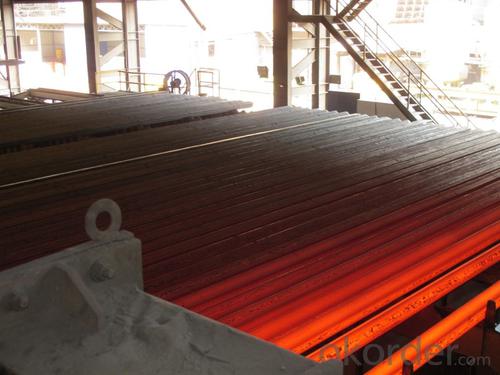

Q235/3SP 90MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 90MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 90MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 90MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 90MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 90MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different types of steel billet handling equipment?

- There are several different types of steel billet handling equipment used in various stages of the steel production process. These equipment are designed to efficiently move and transport steel billets, which are semi-finished metal products used for further processing. 1. Overhead Cranes: Overhead cranes are commonly used in steel mills and foundries for the handling and transportation of steel billets. These cranes have a high lifting capacity and can move billets from one location to another within the facility. 2. Mobile Cranes: Mobile cranes are versatile and can be used for handling steel billets in both indoor and outdoor environments. They are equipped with hydraulic systems for lifting and maneuvering heavy loads. 3. Forklifts: Forklifts are commonly used in warehouses and storage facilities to handle steel billets. They have forks at the front that can be raised and lowered to lift and move the billets. 4. Grab Buckets: Grab buckets are used for handling bulk materials, including steel billets. They have a bucket-like structure that can be opened and closed to grab and release the billets. These are often used in ports and shipping yards for loading and unloading billets from ships. 5. Conveyor Systems: Conveyor systems are used for continuous movement of steel billets along a predefined path. They can be used to transport billets between different stages of the production process or to load and unload them from trucks or trains. 6. Roller Tables: Roller tables are used for transferring steel billets from one conveyor or machine to another. They typically consist of a series of rollers that allow for smooth and controlled movement of the billets. 7. Magnetic Lifters: Magnetic lifters use an electromagnetic field to lift and transport steel billets. They are particularly useful when handling ferrous materials, as the magnetic force allows for secure gripping and easy movement. 8. Palletizers: Palletizers are used to stack and organize steel billets on pallets. They can automatically arrange the billets in a specific pattern, making them suitable for storage or transportation. Each type of equipment has its own advantages and is used in specific applications based on the requirements of the steel production process. The selection of the appropriate handling equipment depends on factors such as the size and weight of the billets, the distance they need to be transported, and the specific needs of the facility.

- Q: How are steel billets used in the production of marine vessels?

- Steel billets are used in the production of marine vessels as they serve as the raw material for various components and structures. These billets are typically shaped and processed to create different parts such as hulls, frames, decks, and superstructures. By being molded and welded together, steel billets provide the necessary strength, durability, and structural integrity required for marine vessels to withstand the harsh conditions of the sea.

- Q: What are the main factors affecting the electrical conductivity of steel billets?

- The electrical conductivity of steel billets is primarily influenced by several key factors. 1. Composition: The chemical composition of steel, particularly the presence of alloying elements, significantly affects its electrical conductivity. Elements such as carbon, manganese, silicon, and phosphorus can alter the conductivity properties of steel. 2. Impurities: The presence of impurities in steel, such as sulfur and oxygen, can lower its electrical conductivity. These impurities can create barriers to the flow of electric current within the material. 3. Grain structure: The grain structure of steel, which is influenced by factors like temperature and cooling rate during the manufacturing process, can impact its electrical conductivity. A fine-grained structure generally results in higher conductivity due to the presence of fewer barriers to electron flow. 4. Heat treatment: The heat treatment process applied to steel billets can affect their electrical conductivity. Specific heat treatments, such as annealing or quenching, can modify the microstructure of the material and consequently impact its conductivity. 5. Temperature: Temperature has a significant effect on the electrical conductivity of steel billets. Generally, as temperature increases, the conductivity decreases due to increased thermal vibrations that impede the flow of electrons. 6. Surface conditions: The surface condition of steel billets, including the presence of oxides, scale, or contaminants, can influence their electrical conductivity. A clean and smooth surface promotes better conductivity by reducing any barriers to electron flow. 7. Mechanical stress: The presence of mechanical stress or strain in steel billets can affect their electrical conductivity. Deformation caused by processes such as rolling, forging, or bending can alter the material's crystal structure and introduce dislocations, which can impact conductivity. Overall, the electrical conductivity of steel billets is a complex property that is influenced by various factors such as composition, impurities, grain structure, heat treatment, temperature, surface conditions, and mechanical stress. Understanding and controlling these factors is crucial for ensuring the desired electrical conductivity in steel billets for various applications.

- Q: What types of steel are commonly used for billets?

- There are several types of steel that are commonly used for billets, depending on the specific application and desired properties. One common type is carbon steel, which is an alloy of iron and carbon. Carbon steel billets are widely used because of their high strength, durability, and affordability. They are suitable for a variety of applications, including construction, automotive, and machinery industries. Another type of steel used for billets is alloy steel. Alloy steel billets are made by adding various alloying elements such as chromium, nickel, and molybdenum to carbon steel. These alloying elements enhance the strength, toughness, and corrosion resistance of the steel, making it suitable for more demanding applications like aerospace, oil and gas, and power generation. Stainless steel is also commonly used for billets, especially in applications where corrosion resistance is critical, such as in marine environments or food processing industries. Stainless steel billets are made by adding chromium and sometimes other elements like nickel or molybdenum to carbon steel. This combination of elements provides excellent resistance to corrosion, high temperatures, and chemicals. Finally, tool steel is another type of steel used for billets, primarily in the manufacturing of tools and dies. Tool steel billets are made with specific alloying elements like tungsten, vanadium, or cobalt, which give them exceptional hardness, wear resistance, and heat resistance properties. These billets are essential for producing precision tools and components used in industries such as automotive, aerospace, and manufacturing. In summary, the types of steel commonly used for billets include carbon steel, alloy steel, stainless steel, and tool steel. The choice of steel depends on the specific application requirements, such as strength, corrosion resistance, or hardness.

- Q: What is the typical composition of steel billets?

- The typical composition of steel billets can vary depending on the specific requirements and intended use. However, in general, steel billets are primarily composed of iron and carbon, with other elements added to enhance certain properties. The carbon content in steel billets is typically around 0.1-0.3%. In addition to iron and carbon, steel billets often contain small amounts of other elements such as manganese, silicon, sulfur, and phosphorus. Manganese helps improve the strength and hardness of the steel while also promoting better heat treatment response. Silicon is commonly added to enhance the steel's fluidity during casting. Sulfur and phosphorus are impurities that need to be minimized as they can negatively affect the steel's machinability and mechanical properties. Furthermore, alloying elements such as chromium, nickel, molybdenum, and vanadium may also be present in steel billets to impart specific properties. For instance, chromium improves corrosion resistance, nickel enhances toughness and ductility, molybdenum increases high-temperature strength, and vanadium improves wear resistance. Overall, the composition of steel billets is carefully controlled to achieve the desired mechanical, physical, and chemical properties required for the subsequent processing and final applications of the steel.

- Q: How are steel billets used in the manufacturing of consumer goods?

- Steel billets are a crucial raw material used in the manufacturing of consumer goods. These billets are primarily utilized as feedstock in various metalworking processes such as hot rolling, forging, and extrusion. By shaping and forming the steel billets into desired shapes, manufacturers are able to produce a wide range of consumer goods like automobiles, appliances, construction materials, and machinery components. The high strength and durability of steel make it an ideal choice for consumer goods, ensuring reliability and longevity in the final products.

- Q: What are the different types of steel billet inspection equipment?

- The manufacturing industry utilizes various types of steel billet inspection equipment to guarantee the quality and integrity of the billets before further processing. These equipment are specifically designed for this purpose. 1. High-frequency sound waves are employed by Ultrasonic Testing (UT) Equipment to detect internal flaws or defects in the steel billets. It can identify cracks, voids, and other imperfections that may impact the final product's strength and performance. 2. Magnetic Particle Inspection (MPI) Equipment utilizes a magnetic field and specially formulated particles to identify surface and near-surface defects in the steel billets. It can uncover cracks, seams, and other imperfections that may not be visible to the naked eye. 3. Eddy Current Testing (ECT) Equipment uses electromagnetic induction to identify surface cracks and defects in the steel billets. It can detect variations in electrical conductivity caused by localized defects or changes in material properties. 4. Visual Inspection Equipment makes use of magnifying glasses, microscopes, and cameras to visually examine the steel billets for surface defects, irregularities, or other visual abnormalities. This equipment is often used together with other inspection methods for a comprehensive analysis. 5. Dimensional Measurement Equipment is employed to measure the dimensional accuracy and consistency of the steel billets. It includes tools such as calipers, micrometers, and laser scanners to ensure that the billets meet the required specifications and tolerances. 6. Surface Roughness Measurement Equipment quantifies the surface finish of the steel billets. It utilizes a stylus or laser to measure surface irregularities, providing crucial information about the billet's suitability for further processing. 7. X-ray Testing Equipment uses electromagnetic radiation to penetrate the steel billets and detect internal defects such as cracks, voids, or inclusions. This method is particularly effective for larger billets or when a comprehensive assessment of the internal structure is necessary. These are some of the commonly utilized steel billet inspection equipment in the manufacturing industry. Each type of equipment plays a vital role in ensuring that the steel billets meet the required quality standards and are appropriate for further processing into various end products.

- Q: How are steel billets used in the production of gear blanks?

- Gear blanks are made from steel billets, which are essential for their production. Steel billets are long bars of steel that possess the necessary characteristics for gear manufacturing. These billets are made from high-quality steel and provide the material needed for creating gear blanks. To shape the gear blanks, the steel billets are heated to a specific temperature, making them easier to work with. Various forming processes, such as forging or extrusion, are then used to transform the billets into the desired shape of the gear blank. Once the gear blank is formed, it undergoes further machining processes to refine its shape, dimensions, and surface finish. This includes turning, milling, drilling, or grinding operations. Precise machining is necessary to meet the required specifications for the final gear product. The gear blanks produced from steel billets are the foundation for creating different types of gears, including spur gears, helical gears, bevel gears, or worm gears. These gear blanks undergo additional steps, such as heat treatment and surface hardening, to enhance their mechanical properties and increase their resistance to wear and fatigue. In conclusion, steel billets are crucial in the production of gear blanks as they provide the raw material for creating gears. Through heating, forming, and machining processes, the steel billets are transformed into gear blanks, which are then further processed to create the final gears used in various applications.

- Q: What are the different types of steel billet forging defects?

- During the forging process, various steel billet forging defects may arise, each with its own causes and potential impact on the final forged product's quality and integrity. The common defects encompass the following: 1. Surface cracks, resulting from excessive heating or cooling, improper forging techniques, or the presence of impurities in the steel, manifest as cracks on the billet's surface. 2. Internal voids, caused by incomplete mold filling, inadequate venting, or trapped gases within the steel, form cavities or voids within the billet. 3. Inclusions, consisting of foreign materials or impurities within the billet, like non-metallic particles (e.g., oxides or sulfides) or metallic impurities (e.g., slag), can weaken the steel structure and diminish overall quality. 4. Segregation, which occurs during the cooling process, refers to the uneven distribution of alloying elements within the billet, leading to different mechanical properties in distinct areas of the steel and resulting in inconsistencies in the final product. 5. Dimensional inaccuracies, arising from improper tooling or die design, inadequate heating or cooling processes, or improper handling during forging, refer to deviations from the desired shape or size of the billet. 6. Grain structure abnormalities, influenced by factors such as improper heating or cooling rates, can weaken the steel and reduce its mechanical properties by altering the grain structure. To ensure the quality and reliability of the final forged product, it is crucial to detect and address these defects during the production process. Quality control measures, including non-destructive testing and visual inspections, can aid in identifying and rectifying these defects before delivering the finished product to the customer.

- Q: How do steel billets compare to other types of raw materials in manufacturing?

- Steel billets are widely recognized as one of the most versatile and commonly used raw materials in manufacturing industries. When compared to other types of raw materials, steel billets offer several advantages that make them highly desirable. Firstly, steel billets have exceptional strength and durability. This characteristic makes them suitable for a wide range of applications, including construction, automotive, and machinery manufacturing. Steel billets are known for their high tensile strength, which ensures the structural integrity of the final product. Secondly, steel billets have excellent heat resistance properties. This makes them ideal for applications that involve exposure to extreme temperatures, such as in the aerospace and energy sectors. Steel billets can withstand high temperatures without compromising their mechanical properties, ensuring the longevity and reliability of the manufactured products. Additionally, steel billets are highly malleable and can be easily shaped into various forms through processes like rolling, forging, or extrusion. This versatility allows manufacturers to create complex and intricate parts, components, and structures, meeting the diverse needs of different industries. Moreover, steel billets are readily available in large quantities, making them a cost-effective choice for manufacturing. The abundance of steel billets in the market ensures a stable supply chain and helps manufacturers avoid potential disruptions caused by material shortages. Lastly, steel billets are known for their recyclability, making them an environmentally friendly choice. Steel is one of the most recycled materials globally, and the use of steel billets in manufacturing contributes to reducing the environmental impact of waste disposal and conserving natural resources. In summary, steel billets outshine other types of raw materials in manufacturing due to their exceptional strength, heat resistance, malleability, cost-effectiveness, and recyclability. These qualities make steel billets a preferred choice for a wide range of industries, offering reliability, versatility, and sustainability in the manufacturing process.

Send your message to us

Q235/3SP 90MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords