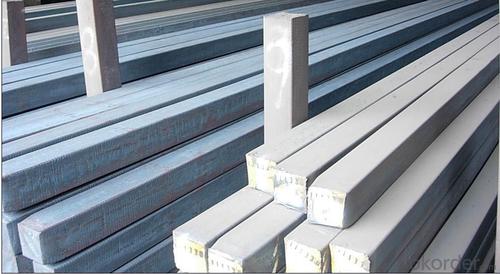

Q235/3SP 120MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Q235/3SP 120MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels consist of a steel substrate with a metallic zinc coating applied by means of a continuous hot dip galvanising process. Metallic zinc coatings are available in steel grades ranging from steel for bending and deep drawing applications, to structural steels and high yield strength steels.

A glossy surface finish obtained under specific skin-pass conditions (either non-skin-passed or skin- passed with smooth cylinders to obtain low roughness) can be provided if required at time of enquiry.

Advantage of Q235/3SP 120MM Blast Furnace Hot Rolled Steel Billet

Uncoated CR steel sheet With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Q235/3SP 120MM Blast Furnace Hot Rolled Steel Billet

Our hot dip galvanised steels can be used in a very wide range of applications for industrial markets, both indoors and outdoors. Some of the most common applications are:

Building: wide sections for roofing and cladding, doors, door frames, metallic ceilings, partitions, structural members etc

Domestic appliances: all appliances for this sector (both white and brown goods) are manufactured with hot dip galvanised steels

Miscellaneous: electrical cabinets, aeraulic components, air conditioners, road signs etc

Zinc hot dip galvanised steel is suitable for contact with foodstuffs under certain conditions, as specified in European directive 89/109/EEC and French standard NF A 36-712-1. Please contact us for further information on this subject.

Specifications of Q235/3SP 120MM Blast Furnace Hot Rolled Steel Billet

Quality | Q/BQB 440-2003 | JIS G3312-1994 JIS G3321 | EN 10326-2004 | ASTM A653-02a |

EN 10327-2004 | (BASE PLATE) | |||

(BASE PLATE) | ||||

Commercial Steel | DC51D | SGCC SGLCC | DX51D+Z DX51D+AZ | CS Type A/B/C |

Forming Steel | St01,St02,St03 | SGCD1 SGLCD1 | FS Type A, Type B | |

Drawing | DC52D /DC53D | - | DX52D+Z DX52D+AZ | DDS TYPE A/C |

Steel | DX53D+Z DX53D+AZ | |||

Structural | S280GD (StE28) | SGC400 SGLC400 | S280D+Z DX54D+AZ | SS275 |

Steel | S350GD (StE34) | SGC440 SGLC440 | S350D+Z S350D+AZ | SS340 Class1 |

FAQ of Q235/3SP 120MM Blast Furnace Hot Rolled Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Are steel billets used in the manufacturing of oil and gas pipelines?

- Yes, steel billets are commonly used in the manufacturing of oil and gas pipelines. Steel billets are semi-finished products that are typically produced through a process called continuous casting, where molten steel is solidified into a rectangular shape. These billets serve as the starting material for various steel products, including pipes used in the oil and gas industry. The manufacturing process of oil and gas pipelines involves several steps, one of which is the production of seamless or welded steel pipes. Steel billets are heated and then rolled into tubes or pipes through a process called pipe making. For seamless pipes, the heated billet is pierced to form a hollow shell, which is then elongated and shaped into a pipe. Welded pipes are created by rolling and welding a flat plate of steel to form a tube. The use of steel billets in pipeline manufacturing is preferred due to the excellent mechanical properties of steel, including its strength, durability, and resistance to corrosion. These properties make steel an ideal material for pipelines that need to withstand high-pressure environments and harsh conditions. Additionally, steel billets can be customized in terms of size, shape, and composition to meet the specific requirements of each pipeline project. In conclusion, steel billets play a crucial role in the manufacturing of oil and gas pipelines. They serve as the raw material that is transformed into seamless or welded pipes, which are then used to transport oil and gas across long distances. The use of steel ensures the reliability and integrity of these pipelines, making them essential components of the oil and gas industry.

- Q: How do steel billets differ from steel ingots?

- Steel billets and steel ingots differ in terms of their shape and size. Steel billets are typically long and narrow, resembling a thick bar or rod, while steel ingots are larger and have a rectangular or square shape. Additionally, steel billets are usually smaller in size compared to steel ingots. Moreover, steel billets are often produced through continuous casting, while steel ingots are typically made through the traditional method of pouring molten steel into molds.

- Q: How are steel billets used in the production of construction machinery?

- Steel billets are used in the production of construction machinery as they serve as the raw material for forging and casting processes. These billets are heated, shaped, and molded into various components such as gears, axles, and frames, which are then assembled to create the construction machinery. The high strength and durability of steel make it an ideal material for construction machinery, ensuring the equipment can withstand heavy loads and harsh working conditions.

- Q: What are the different welding techniques used for steel billets?

- Some of the different welding techniques used for steel billets include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), submerged arc welding (SAW), and laser welding. Each technique has its own advantages and is chosen based on factors such as the thickness of the billet, desired weld quality, and production requirements.

- Q: How are steel billets stored to prevent corrosion?

- In order to prevent corrosion, steel billets are typically stored in a manner that avoids direct contact with moisture and oxygen, which are the primary culprits. One common approach involves keeping the billets indoors in a controlled environment, such as a warehouse or storage facility. These facilities are specially designed to maintain low levels of humidity and often feature climate control systems for temperature and moisture regulation. To provide further protection against corrosion, steel billets can be placed on wooden pallets or racks. This ensures that they are kept away from the ground and any potential sources of moisture. Additionally, it is customary to apply a protective coating or oil film on the surface of the billets before storing them. This coating acts as a barrier, preventing moisture and oxygen from directly contacting the steel and reducing the risk of corrosion. Regular inspections and maintenance are crucial to promptly identify and address any signs of corrosion. This may involve periodic cleaning, applying additional protective coatings, or implementing other preventive measures as needed. By storing steel billets in a controlled environment, applying protective coatings, and conducting regular inspections, the risk of corrosion can be significantly minimized. This ensures that the billets remain in optimal condition for future use.

- Q: Can steel billets be used in the production of utensils and cutlery?

- Utensils and cutlery can indeed be produced using steel billets. These semi-finished products have the potential to be transformed into a variety of shapes and forms, including utensils and cutlery. The remarkable properties of steel, such as its strength, durability, and resistance to corrosion, make it an ideal choice for manufacturing these items. In the production process, steel billets are often melted and cast into specific shapes. They are then further processed through techniques like forging, stamping, or machining to create the desired utensils and cutlery items. The range of final products is extensive, encompassing not only spoons, forks, and knives but also more intricate items like serving spoons, ladles, and cheese slicers. Steel utensils and cutlery are highly regarded and widely used due to their long-lasting nature and hygienic qualities.

- Q: How are steel billets used in the manufacturing of power transmission equipment?

- Steel billets are an essential component in the manufacturing of power transmission equipment. These billets, which are solid blocks of steel, serve as the raw material for various parts and components of power transmission equipment. One of the primary uses of steel billets is in the production of gears and shafts. Gears are crucial in power transmission equipment as they help transfer rotational motion from one component to another. Steel billets are forged and machined into the desired shape and size to create strong and durable gears that can withstand the high forces and speeds associated with power transmission. Similarly, steel billets are also used in the manufacturing of shafts. Shafts are responsible for transmitting rotational motion and torque between different parts of the power transmission system. The strength and reliability of the shafts are crucial for the efficient functioning of power transmission equipment. Steel billets are shaped and machined to create robust and precise shafts that can endure the loads and stresses involved in power transmission. Furthermore, steel billets are used in the production of various structural components of power transmission equipment, such as housings and frames. These components provide support and protection to the internal mechanisms and ensure the equipment operates smoothly. Steel billets are forged, cut, and welded to fabricate sturdy and rigid structures that can accommodate the complex arrangements and dynamic forces of power transmission systems. In summary, steel billets play a crucial role in the manufacturing of power transmission equipment. They are used to create gears, shafts, and structural components that are essential for the efficient and reliable operation of power transmission systems. The strength, durability, and precision of steel billets contribute to the overall performance and longevity of power transmission equipment.

- Q: How do steel billets contribute to the manufacturing of electrical appliances?

- The manufacturing of electrical appliances heavily relies on steel billets, as they offer a strong and long-lasting material for different components. Robust structures are crucial for electrical appliances like refrigerators, washing machines, and air conditioners, as they need to withstand continuous usage and external forces. To create these sturdy structures, semi-finished metal products called steel billets are employed as raw materials in the manufacturing process. To begin with, steel billets are shaped and sized through forging or rolling to produce the frames, chassis, and housing of electrical appliances. These components provide vital support and protection for the internal parts of the appliances. Due to its strength and stability, steel is an ideal choice to endure the weight and vibrations generated during the operation of electrical appliances. Moreover, steel billets are utilized for fabricating the motor cores and transformer cores in electrical appliances. Motor cores play a crucial role in converting electrical energy into mechanical energy, whereas transformer cores regulate voltage in electrical circuits. Steel's magnetic properties, such as high electrical conductivity and low hysteresis loss, make it an excellent option for these applications, ensuring efficient energy conversion and transmission. Furthermore, steel billets are employed in the manufacturing of heating elements and electrical contacts in appliances like stoves, ovens, and switches. These components demand materials that can withstand high temperatures, resist corrosion, and exhibit excellent electrical conductivity. Steel billets are often alloyed with other metals like nickel or chromium to enhance these properties, making them highly suitable for such applications. In conclusion, steel billets make a significant contribution to the manufacturing of electrical appliances by providing a durable and versatile material for various components. The strength, stability, and magnetic properties of steel make it an essential raw material for creating the frames, motor cores, transformer cores, heating elements, and electrical contacts used in these appliances. Thanks to steel billets, electrical appliances can perform reliably and efficiently, meeting the needs and expectations of consumers.

- Q: What are the different types of steel billet welding processes?

- There are several different types of steel billet welding processes that are commonly used in various industries. These processes include: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, SMAW involves a flux-coated electrode that is manually fed into the welding pool. It is a versatile and widely used process for welding steel billets. 2. Gas Metal Arc Welding (GMAW): This process, commonly known as MIG welding, uses a continuously fed wire electrode and a shielding gas to protect the weld pool. It is a popular method for welding steel billets due to its efficiency and ease of use. 3. Flux-Cored Arc Welding (FCAW): FCAW is similar to GMAW, but it uses a tubular electrode filled with flux instead of a solid wire. This process is often preferred for outdoor or windy conditions as the flux provides better protection against atmospheric contamination. 4. Submerged Arc Welding (SAW): SAW involves feeding a consumable electrode and a granular flux into the weld zone, while the arc remains submerged beneath a layer of flux. It is commonly used for welding large steel billets due to its high deposition rates and deep penetration capabilities. 5. Gas Tungsten Arc Welding (GTAW): Also known as TIG welding, GTAW uses a non-consumable tungsten electrode and a shielding gas to protect the weld pool. It is a precise and high-quality welding process suitable for thin steel billets or applications that require exceptional weld aesthetics. 6. Electroslag Welding (ESW): ESW is a highly efficient process used for welding thick steel billets. It involves melting a consumable electrode and the base metal in a molten slag pool, which provides protection and acts as a filler material. 7. Laser Beam Welding (LBW): LBW utilizes a high-energy laser beam to melt and join steel billets together. It is a precise and fast welding process commonly used in industries such as automotive and aerospace. Each of these welding processes has its own advantages and limitations, and the choice of process depends on factors such as the type and thickness of the steel billet, desired weld quality, production requirements, and cost considerations.

- Q: What are the different methods of steel billet surface shot blasting?

- Different industries commonly utilize various methods for shot blasting the surface of steel billets. These methods include the following: 1. Wheel blasting: By using a wheel mechanism, abrasive particles are propelled onto the steel billet's surface. The high-speed rotation of the wheel generates centrifugal force, effectively removing impurities and contaminants. 2. Air blasting: Compressed air is employed to propel abrasive particles onto the steel billet's surface. This high-pressure stream effectively cleans and prepares the surface. 3. Wet blasting: Water is combined with abrasive particles before propelling them onto the steel billet's surface. The addition of water reduces dust and controls heat during the blasting process. Wet blasting is ideal for delicate or controlled surface cleaning. 4. Shot peening: This specialized method enhances the fatigue life and strength of the steel billet's surface. Small steel shots are propelled onto the surface with controlled intensity, creating compressive stresses that prevent crack initiation and propagation. 5. Vacuum blasting: A blast nozzle and vacuum system are utilized in this method. Abrasive particles are propelled onto the steel billet's surface while the vacuum system simultaneously removes spent abrasive particles and loose debris. This ensures a clean and dust-free environment during the blasting process. It's important to consider factors such as the type and condition of the steel billet, desired surface finish, level of contamination, and industry-specific requirements when selecting a method. Each method has its own advantages and limitations, so choosing the appropriate one is crucial for achieving the desired surface quality and cleanliness.

Send your message to us

Q235/3SP 120MM Blast Furnace Hot Rolled Steel Billet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords