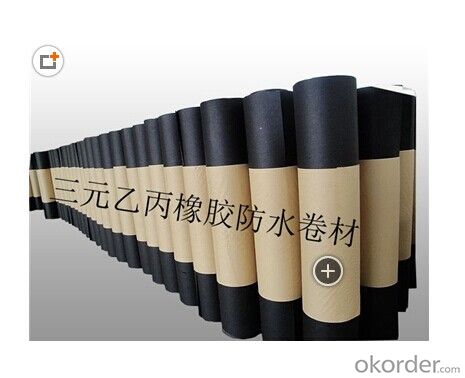

EPDM Rubber Waterproof Membrane with Virgin Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Waterproof Membrane--Top3 manufacturer in China

Detail Information for EPDM Waterproof Membrane

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Features for EPDM Waterproof Membrane

1.Excellent anti-aging performance, service life can reach 50 years;

2.High elongation, high tensile strength, heat treatment size change small;

3.Plant root penetration resistance is good

4.Good low temperature flexibility(-40degree to 150degree)

5.Application is convenient, overlapping is firm and reliable, no environmental pollution;

6. Resistance to chemical corrosion, can be applied to special places;

7.Maintenance is convenient, the cost is low

Application for EPDM Waterproof Membrane

Widely used in roofs, basement, toilet ,swimming pool, and all kinds of industry and civil building waterproofing, reservoir, vivicism, bridge, underground, tunnel and dam waterproofing ,especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation

Specification for EPDM Waterproof Membrane

Type | EPDM Waterproof Membrane | |||

Material | EPDM Rubber | |||

Thickness | 1.0mm; 1.2mm;1.5mm;2.0mm | |||

Weight(kg/m2) | 1.0mm | 1.2mm | 1.5mm | 2.0mm |

1.30-1.34 | 1.54-1.58 | 1.79-1.83 | 2.25-2.29 | |

Length | 20m/Roll | |||

Width | 1.2m/2.05m/4.0m | |||

Usage | basements, ponds, Lake, steel structure roofing, underground, tunnels | |||

Packing | 24/41/80 sqm/roll | |||

Loading in Container | Rolls | |||

Colors | Black | |||

Technical Data for EPDM Waterproof Membrane

Item | value | ||

JL1 | JF1 | ||

Tensile Strength (Mpa) | normal tamperature | 7.5 | 4.0 |

60°C ≥ | 2.3 | 0.8 | |

Elongation at break (%) | normal tamperature ≥ | 450 | 450 |

-20°C ≥ | 200 | 200 | |

Tear Resistance (N) | ≥ | 25 | 18 |

Water impermeability | 30mm | 0.3Mpa | 0.3Mpa |

Cold bending | (°C) ≤ | -40 | -30 |

Heating Shrinking rate | extand << span=""> | 2 | 2 |

shrink << span=""> | 4 | 4 | |

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Are waterproofing membranes resistant to saltwater?

- Yes, waterproofing membranes are generally resistant to saltwater. These membranes are designed to create a barrier that prevents water from penetrating through surfaces such as roofs, walls, or foundations. They are made from materials like rubber, polyethylene, or PVC, which are inherently resistant to the corrosive effects of saltwater. This resistance allows waterproofing membranes to effectively protect structures and surfaces from water damage, even in saltwater environments. However, it is essential to choose a waterproofing membrane specifically designed for saltwater applications to ensure optimal performance and longevity.

- Q: Can a waterproofing membrane be used for stadiums or arenas?

- Yes, a waterproofing membrane can be used for stadiums or arenas. Waterproofing membranes are commonly used in construction to prevent water infiltration, and they can be applied to the roofs, walls, or foundations of stadiums or arenas to protect them from water damage. These membranes are designed to withstand harsh weather conditions and provide long-lasting protection, making them suitable for large-scale structures like stadiums or arenas.

- Q: Can a waterproofing membrane be used on precast copper surfaces?

- Yes, a waterproofing membrane can be used on precast copper surfaces. Waterproofing membranes are versatile and can be applied on a variety of surfaces, including copper. These membranes are designed to create a barrier that prevents water penetration and protects the underlying structure from moisture damage. When applied correctly, a waterproofing membrane can effectively seal precast copper surfaces, providing long-lasting protection against water intrusion. However, it is important to ensure that the membrane is compatible with copper and that proper surface preparation is done before application to ensure optimal adhesion and performance.

- Q: Can a waterproofing membrane be applied on top of existing surfaces?

- Yes, a waterproofing membrane can be applied on top of existing surfaces. However, it is important to ensure that the existing surface is clean, dry, and free from any contaminants or loose materials before applying the membrane. Additionally, proper surface preparation and application techniques should be followed to ensure the effectiveness and longevity of the waterproofing system.

- Q: How does a waterproofing membrane handle movement joints or cracks?

- A waterproofing membrane is designed to accommodate movement joints or cracks by providing flexibility and elasticity. It can stretch and contract to accommodate the movement of the substrate, ensuring that water does not penetrate through the joints or cracks. Additionally, some waterproofing membranes have the ability to self-heal small cracks, further enhancing their effectiveness in handling movement joints or cracks.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures or tears. It is typically made from durable materials such as PVC, TPO, or EPDM, which are known for their strength and resistance to damage. These membranes undergo rigorous testing to ensure their ability to withstand various environmental conditions and potential sources of punctures or tears, such as sharp objects or heavy foot traffic. Additionally, some waterproofing membranes come with reinforcement layers or added protection to further enhance their puncture and tear resistance. However, it is important to note that while waterproofing membranes are highly resilient, they are not completely impervious to damage. Proper installation, regular maintenance, and avoiding unnecessary stress or impact on the membrane can help maximize its longevity and performance.

- Q: Can waterproofing membranes be used in swimming pools?

- Yes, waterproofing membranes can be used in swimming pools. They are commonly used to create a waterproof barrier that prevents water from seeping through the pool walls or floor, ensuring the pool remains watertight.

- Q: Does a waterproofing membrane require any specific surface preparation?

- Yes, a waterproofing membrane typically requires specific surface preparation before installation. This involves cleaning the surface, removing any loose debris, and ensuring it is smooth and dry. Additionally, some membranes may require priming or the use of specific adhesives depending on the type of surface they are being applied to. Proper surface preparation is crucial to ensure effective adhesion and long-lasting waterproofing performance.

- Q: Can a waterproofing membrane be used on copper surfaces?

- Indeed, copper surfaces can be prone to corrosion and moisture-related damage. In order to safeguard them, it is possible to utilize a waterproofing membrane. By implementing this measure, an extra level of protection is afforded. The membrane serves as a barrier, effectively preventing water and moisture from infiltrating the copper surface. Consequently, corrosion is impeded and the lifespan of the copper material is extended. It is crucial to exercise caution when selecting a compatible waterproofing membrane to ensure optimal adhesion and efficacy. Furthermore, it is imperative to diligently adhere to appropriate surface preparation and application techniques to guarantee a triumphant waterproofing solution for copper surfaces.

- Q: Can a waterproofing membrane be used for basements and crawl spaces?

- Basements and crawl spaces can benefit greatly from the use of a waterproofing membrane. To safeguard against water damage and moisture-related problems, it is highly advisable to employ a waterproofing membrane in these areas. The waterproofing membrane functions as a slim layer of material that is applied to the walls and floors of basements and crawl spaces, establishing a barrier against water and moisture infiltration. This technique effectively keeps the area dry and averts water seepage, which can lead to structural deterioration, mold growth, and various other complications. Waterproofing membranes are built to be resilient and enduring, offering a dependable solution for safeguarding basements and crawl spaces against water intrusion.

Send your message to us

EPDM Rubber Waterproof Membrane with Virgin Material

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords