PVC Roofing Waterproof Plastic Membrane Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

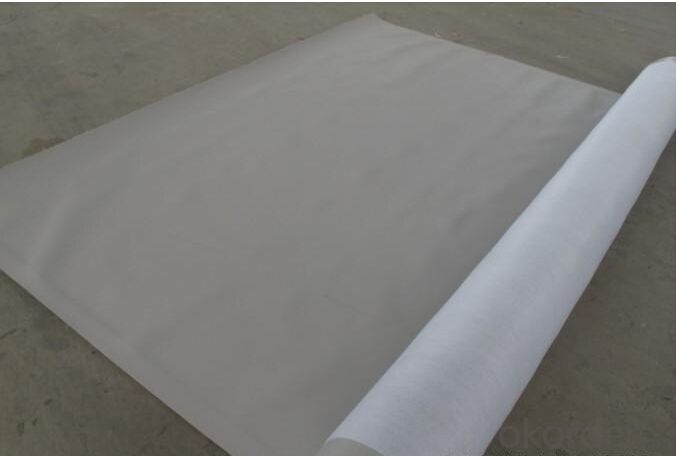

Introduction of PVC Waterproof Membrane

It is an excellent high quality polymer waterproof sheet, made of PVC resin by adding plasticizer, anti-UV agent, anti-aging agent, and stabilizer and other processing aids through extrusion and molding.

As the highly recommended product by the Ministry of Consturction, it is featured by high tensile strength, great elongation, good stability, small shrinkage, low temperature performances, good resistance to weathering and root penetration and long service life.

.

Features of PVC Waterproof Membrane

1)Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2)Root resistant penetration, specially used on planting roofings.

3)Welding installation. Joints are solid and environment friendly, no pollution.

4)High tensile strength, good elongation and dimensional stability.

5)Good plasticity, easy and suitable for details installation.

6)Fireproof. Fire extinguished out of the ignition resource.

7)Surface is smooth, no fading and dirty resistant.

8)Width is over 2m. Construction wastage is small, more economical.

Classification and Specification of PVC Waterproof Membrane

N: Homogeneous PVC membrane

L: PVC membrane with fabric backing

W: Reinforced PVC membrane

Thickness: 1.2mm/1.5mm/2.0mm

Size: 2.05mx20m

Color: white/grey, or any other colors.

Advantage of PVC Waterproof Membrane

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Application of PVC Waterproof Membrane

PVC membrane applies special formula and its service life is much longer than other general waterproof membranes. Its excellent performance makes it be widely used in every field.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be recycled or disposed of in an environmentally friendly manner?

- Indeed, a waterproofing membrane has the potential to be recycled or disposed of in an environmentally conscious manner. Numerous waterproofing membranes are crafted from recyclable materials like polyethylene or polypropylene, which can be repurposed into new products. The act of recycling these membranes not only diminishes waste, but it also conserves resources and lessens the environmental impact associated with manufacturing fresh materials. In order to recycle a waterproofing membrane, it is crucial to consult local recycling facilities or waste management centers to determine if they accept this specific type of material. Some facilities might have specific guidelines or procedures for recycling membranes, thus adhering to their instructions is of utmost importance. In instances where recycling is not feasible, it is still possible to dispose of the waterproofing membrane in an environmentally friendly manner. Numerous waste management facilities allocate designated areas for construction and demolition waste, providing a proper means of disposing the membrane. These facilities employ methods that minimize the environmental impact of the waste, such as containment and controlled disposal techniques. It is of utmost importance to refrain from tossing the membrane in regular trash or illegally dumping it, as this could harm the environment and contribute to pollution. Proper disposal ensures that any potential pollutants or contaminants within the membrane are appropriately managed, thereby preventing harm to ecosystems and human health. In conclusion, by actively engaging in the recycling or environmentally friendly disposal of a waterproofing membrane, we can contribute to a future that is more sustainable and cleaner.

- Q: Can a waterproofing membrane be used in coastal areas?

- Yes, a waterproofing membrane can be used in coastal areas. Coastal areas are prone to high levels of moisture and water exposure, making it essential to have effective waterproofing measures in place. A waterproofing membrane, when properly installed and maintained, can provide a protective barrier against water intrusion, preventing damage to structures and ensuring their durability. However, it is important to select a membrane that is specifically designed for coastal environments, as these membranes are typically more resistant to saltwater and have enhanced durability to withstand the harsh coastal conditions. Additionally, regular inspection and maintenance should be carried out to ensure the effectiveness of the waterproofing membrane in coastal areas.

- Q: Can a waterproofing membrane be used for wastewater treatment plants?

- Yes, a waterproofing membrane can be used for wastewater treatment plants. Waterproofing membranes are commonly used in various construction projects, including wastewater treatment plants, to provide a protective barrier against water infiltration. These membranes are designed to prevent water from seeping into the structure, which is crucial for wastewater treatment plants as they deal with large volumes of water. Wastewater treatment plants are exposed to constant water exposure and high humidity levels, which can lead to moisture damage and structural deterioration. By installing a waterproofing membrane, the facility can effectively prevent water penetration, ensuring the integrity and longevity of the structure. Furthermore, wastewater treatment plants often contain various corrosive chemicals and substances that can cause damage to the structure over time. Waterproofing membranes can act as a protective layer, preventing these chemicals from corroding the building materials and causing structural issues. There are different types of waterproofing membranes available, including sheet membranes, liquid membranes, and cementitious membranes. The choice of membrane depends on the specific requirements, budget, and conditions of the wastewater treatment plant. It is essential to select a membrane that is compatible with the chemicals present in the wastewater and can withstand the harsh conditions of the facility. In conclusion, a waterproofing membrane is a suitable solution for wastewater treatment plants as it effectively protects the structure from water infiltration and chemical damage. By implementing a proper waterproofing system, the facility can ensure the long-term durability and functionality of the plant.

- Q: Can waterproofing membranes be used on wood surfaces?

- Yes, waterproofing membranes can be used on wood surfaces. Waterproofing membranes are versatile products that can be applied to a variety of materials, including wood. They are designed to create a protective barrier that prevents water from penetrating the surface, thereby preventing damage caused by moisture, such as rotting, warping, or mold growth. When applied correctly, waterproofing membranes can effectively seal wood surfaces, making them resistant to water absorption and increasing their durability and lifespan. It is important to choose a waterproofing membrane that is specifically formulated for wood applications and follow the manufacturer's instructions for proper application and maintenance.

- Q: How does a waterproofing membrane handle water pressure from adjacent structures?

- A waterproofing membrane is designed to handle water pressure from adjacent structures by creating a barrier that prevents water from penetrating through it. The membrane is typically installed on the exterior side of the structure, such as the foundation walls, and acts as a protective layer against water infiltration. The membrane itself is usually made of a durable and flexible material, such as rubber, PVC, or bitumen, that is resistant to water and can withstand the pressure exerted by water. It is installed in such a way that it forms a continuous and seamless barrier that covers the entire surface of the structure. When water pressure from adjacent structures, such as soil or groundwater, is exerted on the membrane, it resists the pressure and prevents water from seeping through. This is achieved through the combination of the membrane's material properties and the way it is installed. The waterproofing membrane is typically installed with proper surface preparation, ensuring that the surface is clean, smooth, and free from any debris or sharp objects that could potentially damage the membrane. It is then applied using adhesives, heat fusion, or mechanical fastening techniques to create a secure and watertight seal. In addition to the membrane itself, other components, such as drainage systems and protection boards, may be incorporated into the waterproofing system to further enhance its performance and manage water pressure effectively. These additional components help to divert water away from the structure and relieve any excess water pressure that may build up. Overall, a properly installed and maintained waterproofing membrane is designed to handle water pressure from adjacent structures by creating a reliable and durable barrier that prevents water infiltration and protects the structure from potential water damage.

- Q: Can a waterproofing membrane be used on adobe block surfaces?

- Yes, a waterproofing membrane can be used on adobe block surfaces. Adobe blocks are made from a mixture of clay, sand, and straw, which can be susceptible to water damage. Applying a waterproofing membrane can help prevent water penetration and protect the adobe blocks from moisture-related issues such as cracking, erosion, or mold growth. It is important to ensure that the waterproofing membrane is compatible with adobe surfaces and follows the manufacturer's guidelines for application. Additionally, proper surface preparation and repair of any existing damage is crucial before applying the membrane to ensure its effectiveness.

- Q: What is the recommended temperature range for applying a waterproofing membrane?

- The recommended temperature range for applying a waterproofing membrane is typically between 40°F (4°C) and 90°F (32°C).

- Q: Can a waterproofing membrane be used on brick surfaces?

- Yes, a waterproofing membrane can be used on brick surfaces. The membrane can be applied to protect the brick from moisture, water infiltration, and potential damage caused by water absorption.

- Q: Are there any specific building code requirements for waterproofing membranes?

- Yes, there are specific building code requirements for waterproofing membranes. Building codes vary by jurisdiction, but most codes require that waterproofing membranes meet certain standards and specifications. These requirements are put in place to ensure that buildings are adequately protected from water damage and to maintain the safety and integrity of the structure. Some common building code requirements for waterproofing membranes include: 1. Material standards: The building code may specify the type of materials that can be used for waterproofing membranes. This can include specifications for the type of membrane, such as liquid-applied or sheet membranes, as well as the required thickness and composition. 2. Installation standards: The building code may outline specific installation methods and techniques for waterproofing membranes. This can include requirements for proper surface preparation, application procedures, and detailing around penetrations and transitions. 3. Testing and certification: Building codes may require that waterproofing membranes undergo certain tests and meet specific performance criteria. This can include tests for resistance to water penetration, durability, and compatibility with other building materials. In some cases, the code may require that the waterproofing membrane be certified by a recognized testing laboratory. 4. Code compliance documentation: Building codes often require that waterproofing membranes be installed in accordance with approved plans and specifications. This means that contractors may need to submit documentation to demonstrate compliance with the code, such as product data sheets, manufacturer's installation instructions, and details of the proposed waterproofing system. It is important to consult the local building code or regulatory authority to determine the specific requirements for waterproofing membranes in a particular jurisdiction. Compliance with these requirements is essential to ensure the proper functioning and longevity of the waterproofing system and to avoid potential issues such as water intrusion, mold growth, and structural damage.

- Q: Does a waterproofing membrane have any fire resistance properties?

- No, a waterproofing membrane typically does not have any fire resistance properties. The main purpose of a waterproofing membrane is to provide a barrier against water infiltration and protect the underlying structure from moisture damage. Fire resistance, on the other hand, refers to a material's ability to withstand fire or reduce the spread of flames. Fire resistance properties are typically found in specialized fireproofing materials or coatings, which are designed to prevent the spread of fire and protect the structure in case of a fire incident. It is important to consider both fire resistance and waterproofing requirements when selecting materials for construction projects, as they serve different purposes and may require separate measures to ensure safety.

Send your message to us

PVC Roofing Waterproof Plastic Membrane Best Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords