PVC Waterproofing Membrane of Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

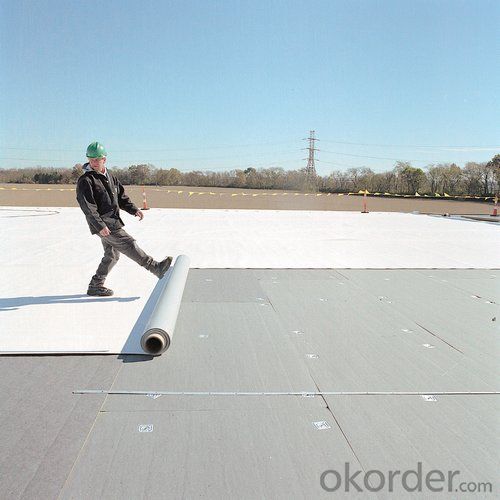

PVC Waterproofing Membrane is widely used to waterproof field as a new kind of membrane.

1.Technical data of PVC Membrane

No. | Item | Index | ||||||

H | L | P | G | GL | ||||

1 | resin thickness over the fabric mm,≥ | — | 0.4 | |||||

2 | tensile strength | max tension (N/CM),≥ | — | 120 | 250 | 120 | ||

tensile strength/Mpa,≥ | 10 | — | — | 10 | — | |||

elongation at max tension/%,≥ | — | — | 15 | — | — | |||

break elongation/%,≥ | 200 | 150 | — | 200 | 100 | |||

3 | thermal size change/%,≤ | 2 | 1 | 0.5 | 0.1 | 0.1 | ||

4 | low temperature flexibility/℃ | —25 no crack | ||||||

5 | impermeability | 0.3MPa,2h impermeable | ||||||

6 | anti-impact | 0.5kg.impermeable | ||||||

7 | static load | 20kg impermeable | ||||||

8 | cut strength/(N/mm),≥ | |||||||

joint peeling strength/(N/mm),≥ | 4 | 3 | ||||||

9 | vertical tearing strength/(N/mm),≥ | 50 | — | — | 50 | — | ||

10 | trapezoid tearing strength/(N/mm),≥ | 150 | 250 | 220 | ||||

11 | water absorption(70℃,160h)% | after saturation≤ | 4 | |||||

after dry≤ | —0.4 | |||||||

12 | heating aging | hour/h | 672 | |||||

appearance | no bubble,crack,seperation | |||||||

tensile strength retention/% | ≥85 | |||||||

elongation retention/% | ≥80 | |||||||

low temperature flexibility retention/℃ | —20 no crack | |||||||

13 | anti chemical property | appearance | no bubble,crack,seperation | |||||

tensile strength retention/% | ≥85 | |||||||

elongation retention/% | ≥80 | |||||||

low temperature flexibility retention/℃ | —20 no crack | |||||||

14 | artificial | hour/h | 1500 | |||||

appearance | no bubble,crack,seperation | |||||||

tensile strength retention/% | ≥85 | |||||||

elongation retention/% | ≥80 | |||||||

low temperature flexibility retention/℃ | —20 no crack | |||||||

2.Characteristic of PVC Membrane

1.Strong tensile strength, high elongation, can fit big deformation of substrates.

2.Excellent anti-extreme weather property, can adapt to various environment temperature difference.

3.Suitable for exposed projects with long lifetime and good anti-aging property.

4.Can be welded firmly and reliably.

5.Outstanding root penetration resistance, best choice for planted roofs.

6.Simple and fast construction without pollution.

7.Great plasticity and fast treatment with corners and details.

3.Applicable scope of PVC Membrane

PVC sheet forms an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway& tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

4. FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for exterior foundation walls?

- Yes, a waterproofing membrane can be used for exterior foundation walls. Waterproofing membranes are designed to provide a protective barrier against water infiltration, and they are commonly used in construction to prevent moisture from entering below-grade structures such as foundation walls. These membranes are typically made of durable materials like rubber, asphalt, or polymer-based compounds that are resistant to water penetration. By installing a waterproofing membrane on the exterior side of foundation walls, it creates a barrier that prevents water from seeping into the foundation, which can help to prevent issues such as water damage, mold growth, and structural deterioration. Additionally, waterproofing membranes can also help to reduce the potential for cracks and leaks in the foundation, enhancing the overall durability and longevity of the structure.

- Q: Can a waterproofing membrane be used for train platforms?

- Yes, a waterproofing membrane can be used for train platforms. Train platforms are exposed to various weather conditions, including rain and snow, which can cause water damage and deterioration over time. By installing a waterproofing membrane on the surface of the train platform, it creates a protective barrier that prevents water from seeping through and causing damage to the underlying structure. This helps to extend the lifespan of the platform, reduce maintenance costs, and ensure the safety of passengers and personnel. Additionally, a waterproofing membrane can also help to prevent the growth of mold and mildew, which can be detrimental to the health of individuals using the train platform. Overall, using a waterproofing membrane on train platforms is a practical and effective solution to protect against water damage and maintain the longevity of the infrastructure.

- Q: Can a waterproofing membrane be used on brass surfaces?

- A waterproofing membrane is typically used to protect surfaces from water penetration and damage. While brass surfaces are not typically prone to water damage, a waterproofing membrane can still be used as an additional protective layer. It can help prevent moisture build-up on the brass surface, which can eventually lead to tarnishing or corrosion. However, it is important to note that brass surfaces are often desired for their natural patina and aesthetic appeal. Applying a waterproofing membrane may alter the appearance of the brass, potentially creating a glossy or artificial finish. Therefore, it is advisable to carefully consider the desired outcome before deciding to use a waterproofing membrane on brass surfaces.

- Q: Can a waterproofing membrane be used in boat decks or marinas?

- A waterproofing membrane is capable of being used in boat decks or marinas. Boat decks and marinas are subjected to constant water exposure, which makes them vulnerable to deterioration and damage over time. To protect these surfaces from water intrusion, a waterproofing membrane offers an effective solution. This prevents issues like rotting, warping, and the growth of mold. Acting as a barrier, the membrane prevents water from seeping into the underlying structure and causing harm. Moreover, it helps maintain the structural integrity of boat decks or marinas, thus extending their lifespan. Furthermore, the use of a waterproofing membrane enhances safety by reducing the risk of slip and fall accidents through the provision of a slip-resistant surface. All in all, opting for a waterproofing membrane for boat decks or marinas is a smart decision to ensure durability, longevity, and safety.

- Q: How does a waterproofing membrane adhere to the surface?

- A waterproofing membrane adheres to the surface through various methods such as mechanical attachment, adhesive bonding, or heat welding. Mechanical attachment involves physically securing the membrane to the surface using fasteners, nails, or screws. Adhesive bonding utilizes a waterproofing adhesive to create a strong bond between the membrane and the surface. Heat welding involves melting the membrane's surface and fusing it with the substrate, creating a watertight seal. The specific method used depends on the type of membrane and the surface to which it is being applied.

- Q: Are there any specific considerations for installing a waterproofing membrane on wood surfaces?

- Installing a waterproofing membrane on wood surfaces requires careful consideration of several factors. The cleanliness and dryness of the wood surface are of utmost importance to establish a strong bond with the membrane. It is essential to choose a membrane specifically designed for wood, considering options like liquid-applied or sheet membranes. Priming the wood surface with a suitable primer is advisable to enhance adhesion and ensure long-lasting waterproofing. Climate and weather conditions should be taken into account to select a membrane that can withstand extreme temperatures and heavy rainfall. Correct installation techniques, such as rolling or brushing the membrane onto the wood surface, must be followed, paying attention to seams, corners, and edges for a secure seal. Regular maintenance and inspection are crucial to detect and address any damage promptly to prevent water infiltration and protect the wood. In conclusion, proper preparation, membrane selection, climate consideration, installation techniques, and maintenance are essential for effective waterproofing and the longevity of wood surfaces.

- Q: How does a waterproofing membrane handle soil movement and settlement?

- Soil movement and settlement are effectively managed by a waterproofing membrane through various mechanisms. Initially, it functions as a barrier between the structure and the soil, thereby preventing water intrusion and minimizing the impact of soil movement on the building. To address soil movement, the membrane exhibits flexibility and elasticity. This enables it to adapt to minor soil shifts and settlements without experiencing cracks or tears. By flexing in conjunction with the movements, the membrane preserves its integrity and sustains its waterproof seal. Moreover, the waterproofing membrane frequently incorporates reinforcements like polyester or fiberglass to enhance its strength and resistance to soil movement. These reinforcements assist in distributing the stress caused by soil settlement across a larger area, thereby reducing the risk of membrane damage. Another crucial consideration is the proper installation and anchoring of the membrane to the structure. This ensures that it remains securely in place even when the surrounding soil moves. Consequently, the membrane avoids shifting or detaching, which may compromise its effectiveness and result in water infiltration. Furthermore, some waterproofing membranes possess self-healing properties. This means that if the membrane sustains punctures or damage due to soil movement, it can automatically seal the breach to prevent water from entering. This self-repairing capability provides an additional layer of protection against damage induced by soil. Overall, a correctly installed and well-maintained waterproofing membrane is specifically designed to withstand soil movement and settlement. Its flexible nature, reinforcements, secure anchoring, and potential self-healing ability enable it to effectively manage these challenges and maintain its waterproofing capabilities over an extended period of time.

- Q: Is a waterproofing membrane resistant to saltwater or other corrosive substances?

- Yes, a waterproofing membrane is typically resistant to saltwater and other corrosive substances. The membrane is designed to provide a protective barrier against moisture and chemicals, ensuring durability and preventing damage caused by corrosive elements.

- Q: Can waterproofing membranes be used on buried pipelines?

- Buried pipelines can benefit from the use of waterproofing membranes. These membranes are specifically designed to shield against water and moisture, and can be applied to a variety of surfaces, including buried pipelines. Typically, these membranes are constructed from materials like bitumen or synthetic polymers, which possess resistance to water penetration. When employed on buried pipelines, waterproofing membranes serve to prevent water infiltration, a process that can lead to corrosion and material deterioration. Acting as a barrier, they effectively halt water from reaching the surface of the pipeline, safeguarding it from potential moisture-induced harm. Furthermore, waterproofing membranes also offer protection against external elements like soil chemicals or gases, which may pose threats to the pipeline. By establishing a waterproof barrier, these membranes effectively extend the lifespan of buried pipelines, diminish maintenance expenses, and enhance overall performance. It is important to emphasize that the selection and application of waterproofing membranes should be entrusted to professionals who possess extensive knowledge in pipeline construction and waterproofing systems. Ensuring the effectiveness of these membranes requires proper installation techniques and compatibility with the pipeline material.

- Q: Can waterproofing membranes be used on precast concrete panels?

- Yes, waterproofing membranes can be used on precast concrete panels. Precast concrete panels can be susceptible to water penetration, which can lead to moisture damage and deterioration of the concrete. Waterproofing membranes are effective in preventing water infiltration by creating a barrier between the concrete surface and the external environment. These membranes are typically applied to the exterior surface of the precast panels, forming a protective layer that prevents water from seeping through the concrete. By using waterproofing membranes, precast concrete panels can be made more durable, longer-lasting, and resistant to moisture-related issues.

Send your message to us

PVC Waterproofing Membrane of Best Quality

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords