PVC Membrane Waterproof /Waterproofing Membrane for Roof

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Waterproof Membrane

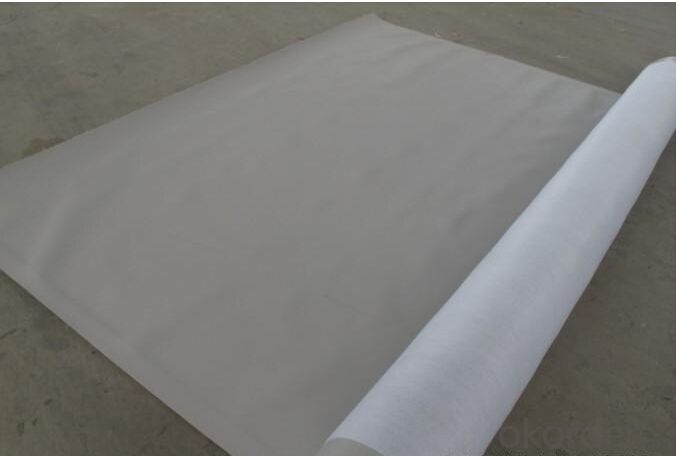

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproof Membrane

1.Excellent aging resistance. Service life of roofing material is over 30 years; service life of underground material is over 50 years.

2. High tensile strength, elongation rate is high, the heat treatment small size change.

3. Good low temperature flexibility, adapt to the environment temperature change.

4. Planting roof root resistance good permeability, can make it.

5. The perforation resistance and good resistance to impact.

6 Construction is convenient, wide width lap welding, solid object, and less reliable and pollution-free.

7. Resistance to chemical corrosion resistance, suitable for special occasions.

8. Have good plasticity, convenient edge details.

9. Convenient maintenance and low cost.

10. Light color of the surface reflection ultraviolet irradiation, coil surface west first fewer calories, low temperature.

11.Coil with good moisture diffusivity, condensate PaiShi easily, keep to the moisture, moisture easy eduction.

Classification of PVC Waterproof Membrane

N1...No composite layer exposed type waterproof material.(type is mainly used in the leakage of roofing waterproof details)

N2...No composite layer non exposed waterproof material.(mainly used in non exposed waterproof details)

L1...Fiber single compound exposed type waterproof material.(type is mainly used in the leakage of roofing waterproof layer of bedding face used)

L2...Fiber single compound non exposed waterproof material.(mainly used for the waterproof layer of bedding face exposed to use)

W1...To enhance the leakage type waterproof material within the fabric.(mainly used in exposed roof waterproof)

W2...To enhance non exposed waterproof material within the fabric.(mainly used in non exposed the waterproof layer)

Advantage of PVC Waterproof Membrane

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproof Membrane

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproof Membrane

PVC membrane applies special formula and its service life is much longer than other general waterproof membranes. Its excellent performance makes it be widely used in every field.

FAQ:

Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: Can a waterproofing membrane be used for temporary structures or tents?

- Yes, a waterproofing membrane can be used for temporary structures or tents. It provides an effective barrier against water infiltration, helping to keep the interior dry and protected from outside elements. This can be especially useful in temporary structures or tents where water resistance is crucial for comfort and safety.

- Q: Can a waterproofing membrane be used on cinder block surfaces?

- Indeed, cinder block surfaces can benefit from the utilization of a waterproofing membrane. Given that cinder blocks possess porosity which allows water absorption, the application of a waterproofing membrane proves advantageous as it obstructs moisture infiltration and averts surface damage. In essence, this membrane functions as a protective barrier, shielding the cinder blocks against moisture-induced concerns like mold, mildew, and deterioration. To ensure optimal adhesion and efficacy, it is crucial to adequately prepare the cinder block surface prior to membrane application. Moreover, selecting a waterproofing membrane specifically tailored for cinder block surfaces yields the most satisfactory outcomes.

- Q: Can a waterproofing membrane be used for underground communication vaults?

- Yes, a waterproofing membrane can be used for underground communication vaults. Waterproofing membranes are commonly used in construction to prevent water infiltration and provide protection against moisture. In the case of underground communication vaults, where moisture and potential water leakage can be a concern, a waterproofing membrane can help ensure the integrity and longevity of the structure by creating a barrier against water intrusion.

- Q: Can a waterproofing membrane be used on masonry surfaces?

- Yes, a waterproofing membrane can be used on masonry surfaces. In fact, applying a waterproofing membrane on masonry surfaces is a common solution to prevent water infiltration and damage. Masonry surfaces such as concrete, brick, or stone are porous and can absorb water, which can lead to structural damage, mold growth, and deterioration over time. A waterproofing membrane acts as a barrier, preventing water from seeping into the masonry and protecting it from moisture-related issues. It is important to choose a waterproofing membrane that is specifically designed for masonry surfaces and follow the manufacturer's instructions for proper application.

- Q: Can a waterproofing membrane be used in areas with high foot traffic or heavy loads?

- Yes, a waterproofing membrane can be used in areas with high foot traffic or heavy loads. Waterproofing membranes are designed to provide a protective barrier against water infiltration and can withstand various types of stress, including foot traffic and heavy loads. However, it is important to choose a waterproofing membrane that is specifically designed for these conditions. There are different types of membranes available, each with varying levels of durability and strength. It is crucial to consult with a professional waterproofing expert or manufacturer to ensure that the chosen membrane is suitable for the specific requirements of the area with high foot traffic or heavy loads. Proper installation and maintenance of the membrane are also essential for its long-term effectiveness in these conditions.

- Q: Are waterproofing membranes suitable for stadium structures?

- Waterproofing membranes are well-suited for stadium structures. Stadiums are exposed to different weather conditions, such as rain, snow, and humidity, which can potentially harm the structure if proper waterproofing measures are not taken. By providing a protective layer that prevents water infiltration, waterproofing membranes safeguard the stadium from moisture-related problems like leaks, mold, and corrosion. Water accumulation on large roof areas and expansive seating areas is common in stadium structures, making waterproofing essential. Membranes can be applied on various surfaces, such as concrete, metal, and wood, offering a versatile and effective waterproofing solution for stadiums. Furthermore, waterproofing membranes offer durability and longevity, which is crucial for stadiums that experience heavy usage and constant exposure to the elements. They are designed to withstand thermal expansion and contraction, as well as UV radiation, ensuring long-term protection for the structure. Moreover, architects and engineers can customize waterproofing membranes to meet specific design requirements, seamlessly integrating them into the stadium's overall aesthetic. These membranes come in various colors, textures, and finishes, allowing them to blend with the surrounding materials and enhance the stadium's visual appeal. In conclusion, waterproofing membranes are a reliable and effective solution for protecting stadium structures from water damage. They provide durability, versatility, and customization options, making them suitable for any stadium construction or renovation project.

- Q: Can a waterproofing membrane be used in conjunction with insulation materials?

- Yes, a waterproofing membrane can be used in conjunction with insulation materials. The membrane acts as a barrier to prevent water infiltration, while insulation materials provide thermal resistance to control heat flow. This combination is commonly used in construction to ensure both waterproofing and insulation performance.

- Q: Can waterproofing membranes be used on concrete slabs?

- Yes, waterproofing membranes can be used on concrete slabs. In fact, it is a common practice to apply waterproofing membranes to concrete slabs to protect them from water damage. Waterproofing membranes are designed to create a barrier that prevents water from penetrating the concrete surface. This is especially important for areas that are exposed to moisture, such as basements, balconies, or swimming pools. By applying a waterproofing membrane, the concrete slab is protected from water infiltration, which can lead to cracks, erosion, or mold growth. Additionally, waterproofing membranes can also enhance the overall durability and lifespan of the concrete slab.

- Q: Can a waterproofing membrane be used on precast cement board surfaces?

- Precast cement board surfaces, commonly utilized in construction, particularly for exterior applications, can benefit from the application of a waterproofing membrane. These surfaces are not inherently waterproof, making it necessary to add an extra layer of protection against water infiltration. The waterproofing membrane, a thin material layer, serves as a barrier on the cement board surface. Its primary function is to prevent water from penetrating the board and reaching the underlying structure. This becomes particularly crucial in areas exposed to moisture, such as bathrooms, kitchens, and outdoor installations. Various types of waterproofing membranes are available, including liquid-applied membranes and sheet membranes. Liquid-applied membranes can be rolled or sprayed onto the surface, while sheet membranes are applied similarly to stickers. Both options effectively waterproof precast cement board surfaces. When selecting a waterproofing membrane for precast cement board surfaces, it is vital to consider the specific requirements and conditions of the project. Factors such as water exposure level, climate, and intended use of the surface should be taken into account. Following the manufacturer's instructions for application is also crucial, as proper installation significantly impacts the membrane's effectiveness. To summarize, the utilization of a waterproofing membrane on precast cement board surfaces provides an additional safeguard against water infiltration. This wise choice is especially beneficial in moisture-prone areas, ultimately extending the lifespan of the cement board and preventing harm to the underlying structure.

- Q: Can a waterproofing membrane be used on plaster surfaces?

- Yes, a waterproofing membrane can be used on plaster surfaces. It provides a protective barrier that prevents water penetration and helps to enhance the durability and longevity of the plaster surface.

Send your message to us

PVC Membrane Waterproof /Waterproofing Membrane for Roof

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords