PVC Membrane Waterproof /Waterproofing Membrane For Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

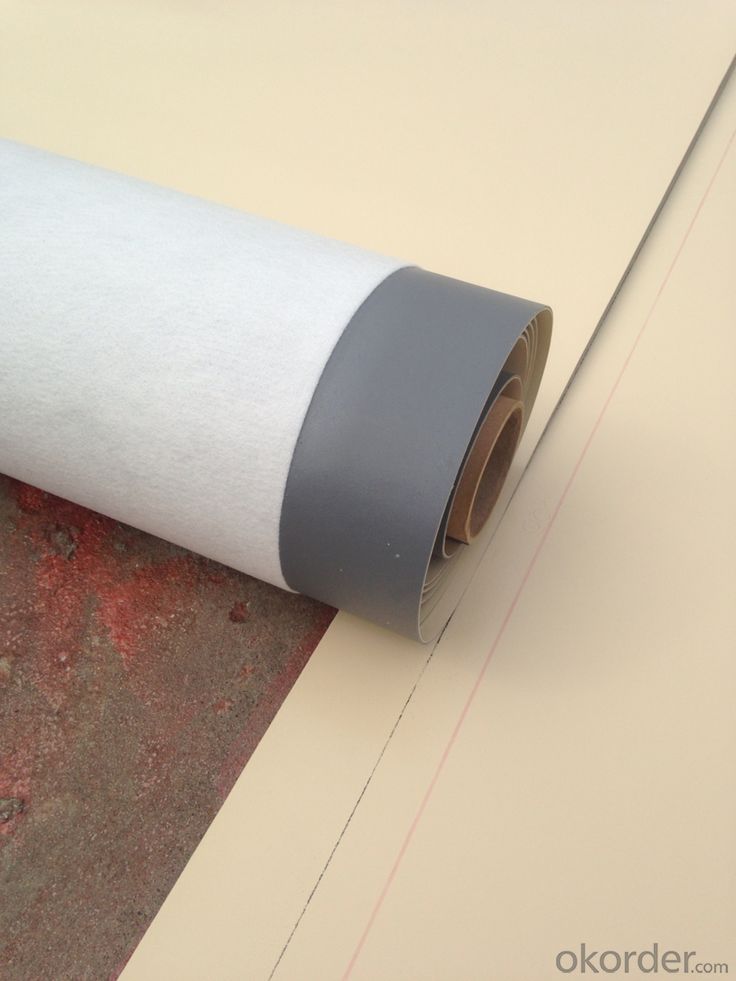

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters:

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Are waterproofing membranes suitable for crawl spaces?

- Yes, waterproofing membranes are suitable for crawl spaces. Crawl spaces are often prone to moisture and water intrusion due to their location and lack of ventilation. Waterproofing membranes provide an effective solution to prevent water damage and moisture-related problems in crawl spaces. These membranes are designed to create a barrier against water and moisture, preventing them from seeping into the crawl space and causing issues such as mold growth, rotting, and structural damage. Additionally, waterproofing membranes can also help to improve indoor air quality by reducing the levels of humidity in the crawl space. Overall, using waterproofing membranes in crawl spaces is highly recommended to ensure a dry, clean, and healthy environment.

- Q: Can waterproofing membranes be used on retaining walls?

- Yes, waterproofing membranes can be used on retaining walls. These membranes are designed to prevent water penetration and can help protect the retaining wall from moisture damage.

- Q: Can a waterproofing membrane be used on crawl spaces?

- Yes, a waterproofing membrane can be used on crawl spaces. It can effectively prevent moisture from seeping into the crawl space, protecting it from water damage and potential mold or mildew growth.

- Q: Can a waterproofing membrane be used in areas with high foot traffic?

- Yes, a waterproofing membrane can be used in areas with high foot traffic. Waterproofing membranes are designed to provide a protective barrier against water infiltration, and many are specifically engineered to withstand heavy use and foot traffic. It is important to choose a high-quality membrane that is durable and suitable for the specific application to ensure long-lasting waterproofing performance in high-traffic areas.

- Q: Does a waterproofing membrane require any special cleaning or maintenance procedures?

- Yes, a waterproofing membrane does require special cleaning and maintenance procedures. While it is designed to be resistant to water and other elements, regular maintenance is important to ensure its longevity and effectiveness. The specific cleaning and maintenance procedures may vary depending on the type of waterproofing membrane used, but generally, it is recommended to keep the membrane clean and free from debris, such as leaves, dirt, or other foreign objects. This can be done by regularly sweeping or gently washing the surface with water and a mild detergent if necessary. Additionally, it is important to inspect the membrane regularly for any signs of damage, such as tears, cracks, or loose seams. Any such issues should be addressed promptly to prevent water infiltration and further damage. In some cases, specialized cleaning products or treatments may be recommended by the manufacturer or installer of the waterproofing membrane. It is important to follow their guidelines and recommendations to ensure the best care and maintenance for the specific membrane used. Overall, regular cleaning and maintenance of a waterproofing membrane will help to extend its lifespan and ensure its continued effectiveness in protecting the underlying structure from water damage.

- Q: Can a waterproofing membrane be used on masonry surfaces?

- Indeed, masonry surfaces can benefit from the utilization of a waterproofing membrane. Employing a waterproofing membrane on masonry surfaces is a prevalent approach to thwart water infiltration and subsequent harm. Concrete, brick, or stone masonry surfaces are permeable and have the capacity to absorb water, resulting in potential structural deterioration, growth of mold, and overall degradation over time. The purpose of a waterproofing membrane is to serve as a barrier, preventing water from permeating the masonry and safeguarding it against moisture-related predicaments. It is crucial to select a waterproofing membrane that is specifically engineered for masonry surfaces and adhere to the instructions provided by the manufacturer for appropriate application.

- Q: Are waterproofing membranes resistant to mold and mildew?

- Waterproofing membranes exhibit resistance to mold and mildew in general. Their purpose is to establish a barrier against moisture, halting its infiltration into the structure and thwarting the growth of mold and mildew. These membranes are commonly crafted from materials like rubber, PVC, or bitumen, which do not foster the development of mold and mildew. Moreover, they are installed in a manner that guarantees effective drainage and ventilation, further diminishing the likelihood of mold and mildew formation. However, it is crucial to bear in mind that although waterproofing membranes significantly decrease the risk of mold and mildew, they are not infallible. It remains imperative to maintain adequate ventilation and promptly address any water leaks or damage to prevent the growth of mold and mildew.

- Q: Can a waterproofing membrane be used on precast cement board surfaces?

- Yes, a waterproofing membrane can be used on precast cement board surfaces. Precast cement board surfaces are commonly used in construction, especially for exterior applications. These surfaces are not inherently waterproof, so applying a waterproofing membrane can provide an extra layer of protection against water infiltration. A waterproofing membrane is a thin layer of material that is applied to the surface of the cement board. It forms a barrier that prevents water from penetrating the board and reaching the underlying structure. This is particularly important for areas that are exposed to moisture, such as bathrooms, kitchens, and outdoor installations. There are different types of waterproofing membranes available, including liquid-applied membranes and sheet membranes. Liquid-applied membranes are typically rolled or sprayed onto the surface, while sheet membranes are applied like a sticker. Both types provide an effective waterproofing solution for precast cement board surfaces. When choosing a waterproofing membrane for precast cement board surfaces, it is essential to consider the specific requirements and conditions of the project. Factors such as the level of water exposure, climate, and intended use of the surface should be taken into account. It is also important to follow the manufacturer's instructions for application, as proper installation is crucial for the effectiveness of the membrane. In conclusion, a waterproofing membrane can be used on precast cement board surfaces to provide additional protection against water infiltration. It is a wise choice for areas that are exposed to moisture and can help prolong the lifespan of the cement board and prevent damage to the underlying structure.

- Q: Can a waterproofing membrane be used for plant rooms or mechanical spaces?

- Yes, a waterproofing membrane can be used for plant rooms or mechanical spaces. Plant rooms and mechanical spaces are areas where equipment, machinery, or systems are installed, and they often contain pipes, tanks, or other components that require protection from water damage. A waterproofing membrane is a durable, flexible, and watertight barrier that can be applied to surfaces such as walls, floors, or ceilings to prevent water infiltration. By using a waterproofing membrane in plant rooms or mechanical spaces, you can ensure the longevity and functionality of the equipment and systems by protecting them from water leaks or moisture damage. Additionally, a waterproofing membrane can also provide a vapor barrier, preventing the buildup of condensation or humidity, which can be detrimental to sensitive equipment.

- Q: Are there any specific considerations for installing a waterproofing membrane on sloped surfaces?

- Yes, there are specific considerations for installing a waterproofing membrane on sloped surfaces. One important consideration is the slope gradient, as steeper slopes may require additional measures to ensure proper adhesion and prevent water pooling. Another consideration is the type of waterproofing membrane used, as some membranes may be better suited for sloped surfaces to provide adequate drainage and prevent water penetration. Additionally, proper surface preparation and installation techniques are crucial to ensure the membrane is properly applied and can withstand the stresses of a sloped surface.

Send your message to us

PVC Membrane Waterproof /Waterproofing Membrane For Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords