PVC Waterproof/waterproofing Membrane For Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

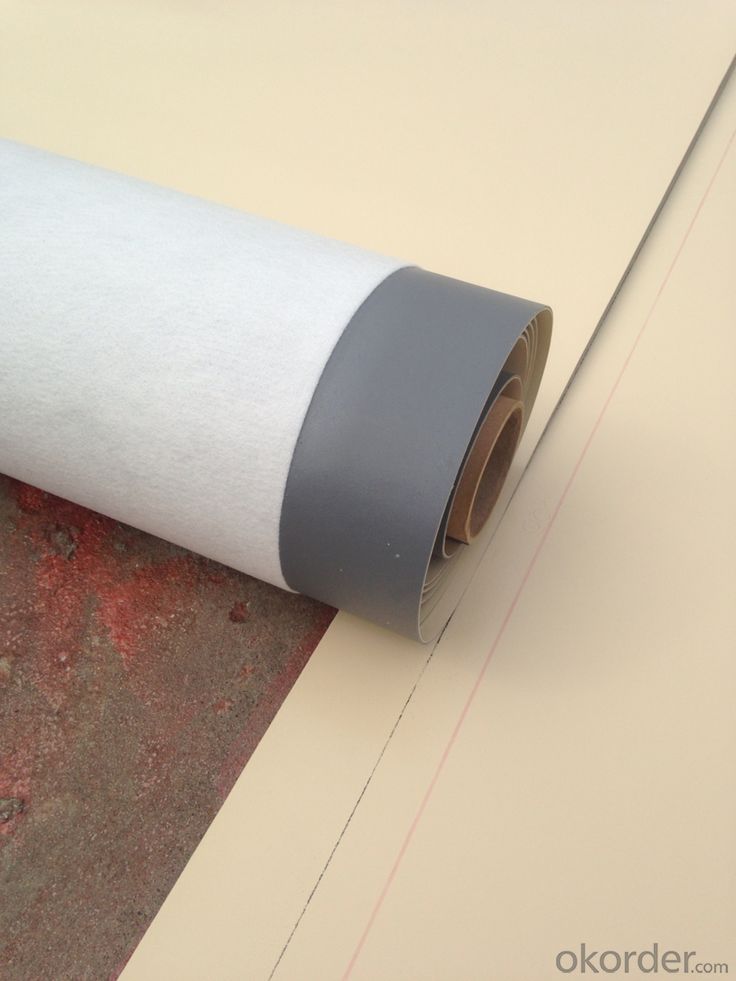

Polyvinyl chloride PVC waterproof membrane is a kind of excellent performance of polymer waterproof material,PVC resin as the main raw material,add all kinds of special additive and anti-aging composition,the use of advanced equipment and advanced technology extrusion rolling is made.The product has the tensile strength and elongation high shrinkage of small,low temperature soft good,long life and other advantages, the products wide 1.2m to 3.0m, the thickness of 0.8-2.0 mm(special specifications can be customized),stable performance,reliable quality,construction is convenient.

Application Scope

The products are widely used in all kinds of civil construction,subway,tunnel,water conservancy,landfill site,chemical industry,metallurgy and other areas of waterproof seepage control,corrosion engineering

Features:

Excellent anti-aging property.

Puncture- resistant.

Welding construction,

High tensile strength, good elongation, good dimensional stability.

Good plasticity.

It has self-extinguishing from fire property.

Materials surface is smooth, fast color, stain resistance.

More wide, Wastage become less when being used.

Type:

N1—Exposed PVC waterproof membrane.

(It is mainly used as details treatment for exposed roof waterproof project)

N2—Non-exposed PVC waterproof membrane.

(It is mainly used as details treatment for non-exposed roof waterproof project)

L1—Exposed PVC waterproof membrane with fabric

(It is mainly used for exposed roof waterproof project)

L2—Non-exposed PVC waterproof membrane with fabric.

(It is mainly used for non-exposed roof waterproof project)

W1—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof exposed waterproof project)

W2—Exposed reinforced PVC waterproof membrane .

(It is mainly used for steel structure roof non-exposed waterproof project)

Advantages

Technical Parameters

No. | Item | Index | |||||

| 1 | Thickness of resin layer of the middle fabric ,mm≥ | - | - | 0.40 | 0.40 | 0.40 | |

| 2 | Tensile performance | Max tensile strength,N/cm ≥ | - | 120 | 250 | - | 120 |

| Tensile strength,NPa ≥ | 10 | - | -10 | - | - | ||

| Max elongation% ≥ | - | - | 15 | - | - | ||

| Breaking elongation % ≥ | 200 | 150 | - | 200 | 100 | ||

| 3 | Heat treatment size change rate%≤ | 2.0 | 1.0 | 0.5 | 0.1 | 0.1 | |

| 4 | Cold bonding | -25°c No cracks | |||||

| 5 | Watertightness | 0.3mPa,2h waterproof | |||||

Packaging & Shipping

product show

FAQ

Q: What's the delivery time ?

A: 3-5 days for 1-600 rolls, 10-15 days for container.

Q: What's the payment terms ?

A: TT/LC

Q: How do you make replacement with quality problems ?

A: New replacement will be packed into your next order or send to you directly after receive video or photo about quality problems.

- Q: Can a waterproofing membrane be used on PVC roofs?

- PVC roofs, commonly found in commercial and residential buildings, are known for their durability and resistance to weathering. However, like all roofing materials, they can develop leaks and cracks over time. To combat this issue, a waterproofing membrane can be applied to PVC roofs. This membrane, such as EPDM or TPO, is flexible and can easily adhere to the PVC surface, forming a seamless and watertight barrier. It is crucial to ensure that the chosen waterproofing membrane is compatible with PVC roofs and to carefully follow the manufacturer's instructions for proper installation. Additionally, regular maintenance and inspections are highly recommended to promptly detect and address any potential problems before they worsen.

- Q: Are waterproofing membranes suitable for exterior use?

- Yes, waterproofing membranes are suitable for exterior use. They are designed to provide a protective barrier against water infiltration and can be applied to various exterior surfaces such as roofs, foundations, and walls. Waterproofing membranes are effective in preventing water damage and maintaining the integrity and longevity of the structure.

- Q: Is a waterproofing membrane resistant to gasoline or other petroleum-based substances?

- Waterproofing membranes are typically able to resist gasoline and other substances that are petroleum-based. These membranes are commonly manufactured from materials like polyurethane or PVC, which are recognized for their ability to withstand chemicals and petroleum products. This resistance guarantees that the membrane remains intact and effective at preventing water from infiltrating even when it is exposed to gasoline or other petroleum-based substances. However, it is crucial to mention that the actual level of resistance may vary depending on the type and quality of the waterproofing membrane being used. It is recommended to seek advice from a professional or review the product specifications to ensure that the selected membrane is suitable for the intended application involving gasoline or petroleum-based substances.

- Q: Can a waterproofing membrane be installed on a sloping surface?

- Yes, a waterproofing membrane can be installed on a sloping surface. In fact, it is often necessary to install a waterproofing membrane on sloping surfaces to ensure proper water drainage and prevent water seepage.

- Q: Can waterproofing membranes be used on utility manholes?

- Yes, waterproofing membranes can be used on utility manholes. Waterproofing membranes provide a protective layer that prevents water infiltration into the manhole, helping to maintain its structural integrity and prevent damages caused by water exposure.

- Q: Can a waterproofing membrane be used for a fountain basin?

- Indeed, a fountain basin can make use of a waterproofing membrane. The purpose of such a membrane is to create a shield against water infiltration, safeguarding the foundation from moisture-related harm. As a fountain basin is consistently subjected to water, implementing a waterproofing membrane aids in averting leaks and securing the basin's durability. It is essential to select a membrane explicitly crafted for water containment and capable of enduring perpetual water exposure and inclement weather conditions. Furthermore, correct installation and maintenance of the membrane are pivotal for its efficacy in preserving the waterproofness of the fountain basin.

- Q: Can a waterproofing membrane be used for zoos or aquariums?

- Yes, a waterproofing membrane can be used for zoos or aquariums. Waterproofing membranes are designed to prevent water penetration and provide a watertight barrier, making them suitable for use in areas that require high levels of water resistance such as zoos or aquariums where water containment is critical.

- Q: Can a waterproofing membrane be used for pond or pool applications?

- Yes, a waterproofing membrane can be used for pond or pool applications. These membranes are specifically designed to create a water-tight barrier, making them suitable for preventing leaks and ensuring the structural integrity of ponds and pools.

- Q: Can a waterproofing membrane be installed on curved surfaces?

- Yes, a waterproofing membrane can be installed on curved surfaces. The flexibility and stretchability of the membrane allow for easy installation and adaptation to different surface shapes, including curved surfaces.

- Q: Can a waterproofing membrane be used for a planter box wall?

- Yes, a waterproofing membrane can be used for a planter box wall. The membrane will help to prevent water from seeping into the wall, which can cause damage over time. Additionally, it will also help to protect the wall from moisture-related issues such as mold or mildew.

Send your message to us

PVC Waterproof/waterproofing Membrane For Roof

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords