Products Description of TPO Waterproof Membrane for Roofing Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

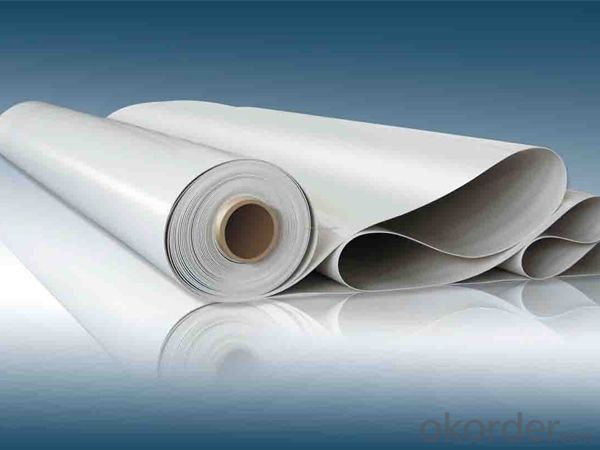

Products Description of TPO Waterproof Membrane for Roofing Construction:

The Thermoplastic Polyolefin (TPO) waterproof membranes are the most popular waterproof materials in the world at present. It’s thermoplastic elastomeric waterproof materials by adopting advanced polymerization together with squeeze technology,which perform well in mechanical properties, high tensile strength,oxidation-resistance and resistance to puncture.

Product Features of TPO Waterproof Membrane for Roofing Construction:

--High UV-resistance and high reflectivity

--Excellent weathering characteristics and long-term flexibility

--High tensile strength and puncture resistance

--Excellent resistance to harsh chemicals and industrial pollutas

--Heat or solventwelding effectively provides seamless roof covering

Data Sheet of TPO Waterproof Membrane for Roofing Construction:

Type | Thickness (mm) | Weight (kg/sqm) | Roll Size (m) | Colors | 20ft Container |

Homogeneous TPO waterproof membrane | 1.0 mm | 1.63kg/sqm | 2.05m x 20m | White/ Grey | 340 rolls/ 14000 sqm |

1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm | |

1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm | |

Reinforced TPO waterproof membrane | 1.2 mm | 1.83kg/sqm | 2.05m x 20m | White/ Grey | 285 rolls/ 12000 sqm |

1.5 mm | 2.24kg/sqm | 2.05m x 20m | White/ Grey | 240 rolls/ 10000 sqm | |

2.0 mm | 2.30kg/sqm | 2.05m x 20m | White/ Grey | 215 rolls/ 9000 sqm |

FRQ:

What is your main market?

Our Tpo Roofing Membrane with Superior Raw Material for Roofing Market sells very well in USA, United Kingdom, Austrilia, Canada, Japan, Pakistan, etc.

What is your advantage for Tpo Roofing Membrane?

With the most advanced production line, our good quality is based on superior material imported from America. We have different color available and could produce any color you want.

- Q: Can a waterproofing membrane be used on balconies and decks?

- Yes, a waterproofing membrane can be used on balconies and decks. In fact, it is highly recommended to install a waterproofing membrane to protect these areas from water damage. Balconies and decks are exposed to rain, snow, and other weather elements, which can cause water to seep into the structure and lead to issues such as rotting, mold growth, and structural damage. A waterproofing membrane provides a protective barrier that prevents water from penetrating the surface and directs it away from the structure. It is typically applied underneath the surface material, such as tiles or decking, and acts as a waterproof layer. This helps to extend the lifespan of the balcony or deck, ensuring its durability and maintaining its aesthetic appeal. Additionally, using a waterproofing membrane can also prevent water from dripping down to the areas below, which is particularly important for balconies located above living spaces. Overall, using a waterproofing membrane is an effective solution to ensure the longevity and functionality of balconies and decks.

- Q: Can a waterproofing membrane be used for a rooftop garden?

- Yes, a waterproofing membrane can be used for a rooftop garden. A waterproofing membrane provides an effective barrier against water penetration, preventing leaks and protecting the underlying structure. This is essential for rooftop gardens as they require proper drainage to ensure plants' health and prevent water damage to the building. Additionally, a waterproofing membrane helps retain moisture within the garden, minimizing water loss.

- Q: What is a waterproofing membrane?

- A waterproofing membrane is a thin layer or sheet made of materials like bitumen, rubber, or synthetic polymers that are applied to surfaces to prevent water penetration. It acts as a barrier, protecting structures such as roofs, basements, or foundations from water damage and leaks.

- Q: Can a waterproofing membrane be used in conjunction with soundproofing materials?

- Yes, a waterproofing membrane can be used in conjunction with soundproofing materials. While the primary function of a waterproofing membrane is to prevent water infiltration, it can also contribute to sound insulation to some extent. However, for optimal soundproofing, it is recommended to use dedicated soundproofing materials such as acoustic insulation or soundproof panels in addition to the waterproofing membrane.

- Q: Are waterproofing membranes suitable for underground parking garages?

- Yes, waterproofing membranes are suitable for underground parking garages. They provide an effective barrier against water infiltration, preventing damage to the structure and protecting against potential leaks and moisture-related issues. Waterproofing membranes are designed to withstand the high water pressure typically associated with underground environments, making them an ideal solution for ensuring the longevity and durability of underground parking garages.

- Q: Can a waterproofing membrane be used on precast iron surfaces?

- Yes, a waterproofing membrane can be used on precast iron surfaces. The membrane acts as a barrier to prevent water penetration, protecting the iron surface from corrosion and water damage.

- Q: Can waterproofing membranes be used on concrete pipes?

- Yes, waterproofing membranes can be used on concrete pipes. Waterproofing membranes are commonly used to prevent water penetration and protect concrete structures from moisture damage. Concrete pipes, like any other concrete structure, are susceptible to water infiltration, which can lead to deterioration and reduced lifespan. Applying a waterproofing membrane to concrete pipes can help to create a barrier against water and prevent potential issues such as leaks, cracks, and corrosion. The membrane is typically applied to the exterior of the pipe, forming a protective layer that prevents water from seeping into the concrete. This can help to extend the lifespan of the pipes and ensure their long-term durability.

- Q: Can waterproofing membranes be used on concrete surfaces?

- Yes, waterproofing membranes can be used on concrete surfaces. Waterproofing membranes are designed to create a barrier against water penetration, and they are commonly used on concrete surfaces to protect them from water damage. These membranes are typically made of materials such as rubber, PVC, or bitumen, and they are applied to the concrete surface in a liquid or sheet form. Once applied, the membrane forms a continuous and durable waterproof layer that prevents water from seeping into the concrete. This is particularly beneficial in areas that are prone to water exposure, such as basements, bathrooms, or exterior concrete structures. Waterproofing membranes can effectively extend the lifespan of concrete surfaces by preventing water-related issues such as cracking, spalling, or mold growth.

- Q: Can a waterproofing membrane be used on elevator pits?

- Indeed, elevator pits can benefit from the utilization of a waterproofing membrane. Given their subterranean position and susceptibility to water infiltration, elevator pits are prone to water damage. By implementing a waterproofing membrane within the elevator pit, the structure can be shielded from water damage, consequently averting issues like corrosion, mold proliferation, and deterioration. Acting as a barrier, the membrane obstructs water from permeating the pit, thereby preventing harm to the elevator apparatus or the surrounding edifice. It is vital to meticulously select a waterproofing membrane specifically engineered for subterranean applications and ensure the installation adheres to proper protocols to achieve effective waterproofing in elevator pits.

- Q: Can a waterproofing membrane be used for swimming pools?

- Yes, a waterproofing membrane can be used for swimming pools. Waterproofing membranes are commonly used in swimming pool construction and renovation projects to prevent water leakage and ensure the pool remains watertight. These membranes are specifically designed to withstand constant exposure to water and provide a durable and long-lasting solution for swimming pools.

Send your message to us

Products Description of TPO Waterproof Membrane for Roofing Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 600000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords