Prime Steel Billet Q275, 20MnSi, 5SP,Q235 for good sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STEEL BILLET

1.Brief description

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

2.Features

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

3.Processing

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

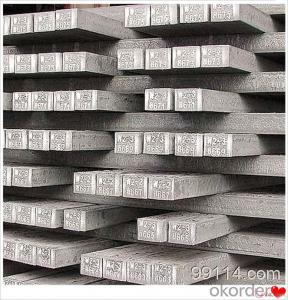

4.Pictures

5.Usage

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

6.Detailed specification

Hot rolled billet steel

Size: 50x50mm-180x180mm

Steel Grade: 3SP, 5SP,Q195,Q235,Q255,Q275 Length:3m-12m

MOQ: 1000MT/size

Payment term: TT or LC

Packing: in bulk , bundle

Shipment: by container , bulk vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: 15-30 days after the deposit

Loading port:Tianjin, or other port China

Origin : China

Inspection:Third party inspection before loading.

- Q: What are the main factors that affect the availability of steel billets?

- There are several main factors that affect the availability of steel billets. Firstly, the availability of raw materials plays a crucial role. Steel billets are produced by melting iron ore, along with other materials such as coal and limestone, in a blast furnace. The availability and cost of these raw materials can greatly impact the production of steel billets. Any disruptions in the supply chain, such as a shortage of iron ore or a spike in prices, can lead to a decrease in the availability of steel billets. Secondly, the demand for steel billets also influences their availability. The construction and manufacturing industries are the primary consumers of steel billets, using them to produce various steel products such as bars, rods, and beams. If there is a surge in demand for steel products, it can strain the availability of steel billets, especially if the production capacity is not able to keep up with the increased demand. Furthermore, market dynamics and economic conditions can impact the availability of steel billets. Factors such as fluctuations in steel prices, changes in government policies, and trade barriers can affect the overall supply and demand balance. For example, the implementation of tariffs or restrictions on steel imports can reduce the availability of steel billets in a particular region, as domestic production may not be able to meet the demand. Additionally, technological advancements and production capabilities also play a role in determining the availability of steel billets. Improvements in manufacturing processes, such as the use of electric arc furnaces or continuous casting, can increase production efficiency and output. On the other hand, any technical issues or maintenance problems in steel plants can lead to disruptions in production and subsequently reduce the availability of steel billets. In conclusion, the availability of steel billets is influenced by factors such as the availability and cost of raw materials, the demand for steel products, market dynamics, economic conditions, and technological advancements. These factors can individually or collectively impact the availability of steel billets, and it is important for stakeholders in the steel industry to monitor and address these factors to ensure a stable supply of steel billets.

- Q: What are the specifications for stainless steel billets used in the marine industry?

- The specifications for stainless steel billets used in the marine industry typically include a specific grade of stainless steel, such as 316 or 316L, which offers excellent corrosion resistance in marine environments. These billets are often required to meet certain standards, such as ASTM A276 or ASTM A484, which outline the chemical composition, mechanical properties, and dimensional tolerances for stainless steel products. Additionally, the billets may need to undergo specific heat treatment processes, such as annealing or solution treatment, to ensure optimal strength and corrosion resistance.

- Q: How do steel billets contribute to the overall recyclability of a structure?

- Steel billets play a significant role in enhancing the overall recyclability of a structure. These billets, which are semi-finished steel products, are produced by melting iron ore and other raw materials in a blast furnace. Due to their composition and manufacturing process, steel billets possess several characteristics that contribute to the recyclability of a structure. First and foremost, steel is one of the most recycled materials on the planet. Steel billets can be recycled indefinitely without losing their quality or integrity. This means that at the end of a structure's lifespan, the steel components can be easily dismantled and the steel billets can be melted down to produce new steel products. The ability to recycle steel billets reduces the need for extracting and refining new iron ore, which in turn conserves natural resources and minimizes the environmental impact associated with mining activities. Furthermore, the recycling process of steel billets requires significantly less energy compared to the production of steel from raw materials. Recycling steel billets consumes around 75% less energy compared to producing steel from scratch. This energy efficiency not only reduces greenhouse gas emissions but also contributes to cost savings during the manufacturing process. By using recycled steel billets in the construction of structures, we can reduce the carbon footprint and promote sustainable practices in the construction industry. In addition to the environmental benefits, the use of steel billets in structures also offers practical advantages. Steel is known for its strength, durability, and resilience, making it an ideal material for constructing robust and long-lasting structures. By incorporating steel billets, structures can be designed to withstand various environmental conditions, such as earthquakes and hurricanes, ensuring the safety and longevity of the building. This longevity aspect is crucial in terms of recyclability, as it allows the structure to serve its purpose for an extended period before being recycled. In conclusion, steel billets contribute significantly to the overall recyclability of a structure. Their ability to be recycled indefinitely, reduced energy consumption during the recycling process, and practical advantages such as strength and durability make steel billets an excellent choice for constructing sustainable and recyclable structures. By incorporating steel billets, we can promote a circular economy, conserve natural resources, reduce emissions, and create a more sustainable future for construction.

- Q: What are the potential defects or flaws in steel billets?

- There are several potential defects or flaws that can occur in steel billets, which can affect the quality and performance of the final product. Some of these defects include: 1. Surface defects: Steel billets can develop surface cracks, scales, or scratches during the manufacturing process. These defects can weaken the material and reduce its structural integrity. 2. Internal defects: Inclusions, such as non-metallic impurities or gas bubbles, can be present within the steel billets. These internal defects can cause localized weaknesses and reduce the overall strength of the material. 3. Segregation: Uneven distribution of alloying elements or impurities can lead to segregation, where certain areas of the billet have different chemical compositions. Segregation can result in inconsistent mechanical properties across the material and decrease its uniformity. 4. Central segregation: This defect occurs when there is a concentration of impurities or alloying elements in the central region of the billet, leading to a weaker core. Central segregation can cause structural failures and reduce the overall reliability of the steel billet. 5. Shrinkage cavities: During the solidification process, shrinkage cavities can form in the steel billet due to the contraction of the molten metal. These cavities can weaken the material and compromise its structural integrity. 6. Surface decarburization: Exposure to high temperatures or improper heat treatment can cause the surface of the steel billet to lose carbon content, resulting in surface decarburization. This defect can reduce the hardness and strength of the material. 7. Laminations: Laminations are thin, elongated voids or layers that can form parallel to the surface of the billet. These defects can weaken the material and make it prone to cracking or failure under stress. 8. Internal cracks: Internal cracks can occur due to improper cooling or handling of the billet during the manufacturing process. These cracks can compromise the structural integrity of the steel billet and potentially lead to catastrophic failure. It is important to detect and address these defects early on to ensure the quality and reliability of the steel billets. Various non-destructive testing techniques, such as ultrasonic testing or magnetic particle inspection, can be utilized to identify and mitigate these potential flaws.

- Q: Are steel billets used in the aerospace industry?

- Yes, steel billets are indeed used in the aerospace industry. Steel is a crucial material in the aerospace sector due to its high strength, durability, and resistance to corrosion. Steel billets, which are semi-finished steel products in a solid form, are used as raw materials for manufacturing various components in aircraft and spacecraft construction. These billets are often further processed through forging, rolling, or extrusion to create specific shapes and sizes required for aerospace applications. These components include structural parts like frames, wings, landing gears, and engine components, where the strength and reliability of steel are essential to ensure the safety and performance of the aircraft. Additionally, steel billets are also used in the manufacturing of tools, fixtures, and machinery used in the aerospace industry. Overall, steel billets play a significant role in the aerospace industry, contributing to the production of robust, reliable, and high-performance aerospace equipment.

- Q: Can steel billets be used in the production of jewelry?

- No, steel billets cannot be used in the production of jewelry. Jewelry is typically made from precious metals such as gold, silver, or platinum, which offer a higher level of aesthetic appeal and value. Steel, being an alloy primarily used in construction and manufacturing industries, lacks the desired characteristics and appearance required for jewelry production.

- Q: How do steel billets contribute to the manufacturing of HVAC equipment?

- Steel billets are an essential raw material in the manufacturing of HVAC equipment because they serve as the base material for various components such as ductwork, frames, and structural supports. The high strength and durability of steel billets make them suitable for withstanding the demanding operating conditions of HVAC systems. Additionally, steel billets can be easily shaped and formed into intricate designs, allowing manufacturers to create complex components that optimize the efficiency and performance of HVAC equipment.

- Q: What is the role of steel billets in the construction of bridges?

- Steel billets play a critical role in the construction of bridges. These long, rectangular bars of steel are often used as raw material to produce various structural components of a bridge. One of the primary uses of steel billets in bridge construction is for the fabrication of beams and girders. These components provide the necessary support and load-bearing capacity to ensure the bridge can withstand the weight of vehicles, pedestrians, and other loads. Steel billets are heated and then rolled into the desired shape to create these structural elements, which are subsequently welded or bolted together to form the bridge's framework. Additionally, steel billets are also used to produce reinforcement bars, commonly known as rebar. Rebar is essential in providing tensile strength to concrete structures, including bridge foundations, piers, and abutments. By reinforcing the concrete with steel billets in the form of rebar, bridges can withstand the forces caused by heavy traffic, wind, and other external factors. The use of steel billets in bridge construction offers several advantages. Firstly, steel is incredibly strong and has a high strength-to-weight ratio, making it an ideal material for bridges. Steel billets can withstand heavy loads and provide the necessary structural integrity, ensuring the longevity and durability of the bridge. Moreover, steel is highly resistant to corrosion, which is crucial for bridges exposed to harsh weather conditions and environmental factors. Corrosion can weaken the structure of a bridge, compromising its safety and longevity. However, by using steel billets, which can be coated or galvanized to enhance corrosion resistance, bridges can maintain their structural integrity over an extended period. In conclusion, steel billets play a vital role in the construction of bridges. They are used to fabricate beams, girders, and rebar, providing the necessary strength, support, and durability to withstand heavy loads and external forces. Steel billets contribute to the overall safety, longevity, and functionality of bridges, making them a critical component in bridge construction.

- Q: How are steel billets used in the manufacturing of pressure vessel components?

- Steel billets are used in the manufacturing of pressure vessel components by being melted and formed into the desired shape through processes like casting, forging, or extrusion. These billets serve as the raw material for creating various components such as shells, heads, and nozzles, which are then further processed, machined, and assembled to construct the pressure vessel.

- Q: How do steel billets contribute to the infrastructure development sector?

- Steel billets play a crucial role in the infrastructure development sector by serving as the foundation for various construction projects. These billets are used to produce structural steel products, such as beams, columns, and reinforcement bars, which are essential components in building bridges, highways, buildings, and other infrastructure projects. The strength and durability of steel billets make them ideal for withstanding heavy loads and adverse weather conditions, ensuring the long-term stability and safety of structures. Moreover, their versatility allows for easy fabrication and customization, enabling engineers and architects to design innovative and efficient solutions for infrastructure development. Overall, steel billets provide the necessary strength, reliability, and flexibility to support the growth and sustainability of the infrastructure development sector.

Send your message to us

Prime Steel Billet Q275, 20MnSi, 5SP,Q235 for good sale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords