Prime Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prime Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel in Hot Sale

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel Prime Steel Billet

Specification (see below)

Standard: GB/JIS/ASTM

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

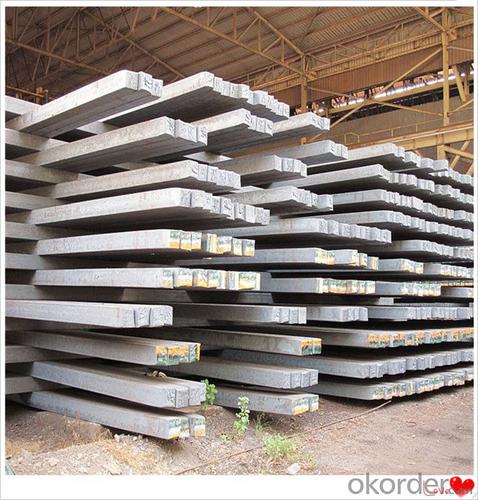

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

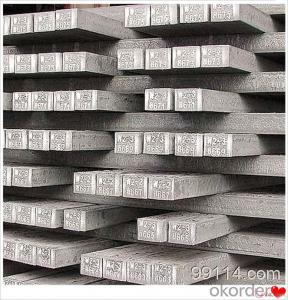

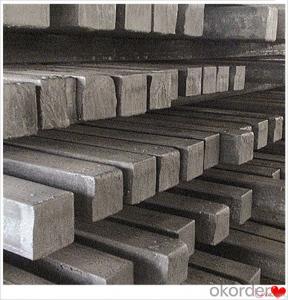

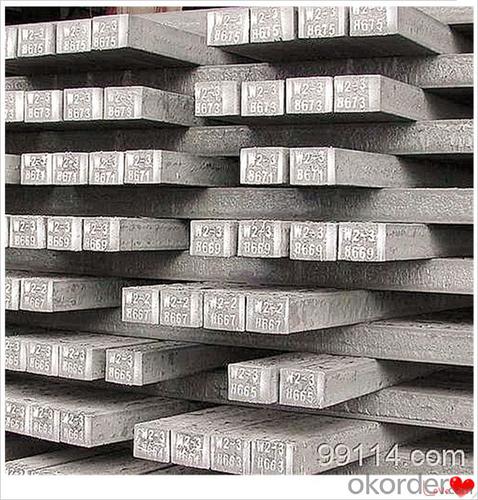

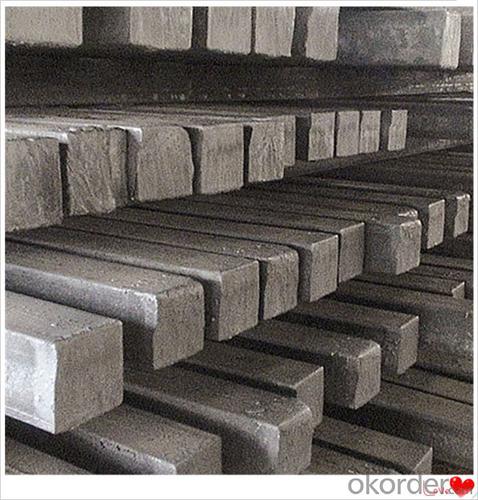

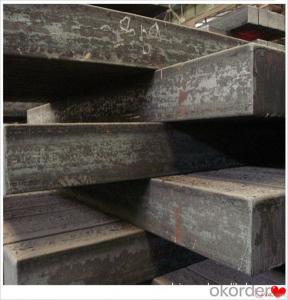

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What is the role of steel billets in the construction of stadiums and arenas?

- Steel billets play a crucial role in the construction of stadiums and arenas. These billets, which are essentially semi-finished steel products, serve as the raw material for various structural components used in the construction process. One of the primary applications of steel billets in stadium and arena construction is for the fabrication of steel beams and columns. These structural elements provide the necessary support and stability to the overall structure. Steel billets are first heated and then passed through rolling mills to acquire the desired shape and size required for these beams and columns. Moreover, steel billets are also used in the production of steel reinforcing bars, commonly known as rebars. These rebars are used to reinforce the concrete structures within stadiums and arenas, such as foundations, walls, and floors. The combination of steel and concrete enhances the structural integrity and load-bearing capacity of these structures, making them capable of withstanding heavy loads, vibrations, and external forces. Additionally, steel billets are utilized in the construction of roof trusses and frames, which provide support for the stadium or arena's roofing system. These steel components offer the necessary strength and durability to withstand the weight of the roof, while also ensuring the overall stability of the structure. Furthermore, steel billets are employed in the production of seating structures, staircases, handrails, and other architectural elements within stadiums and arenas. These components not only contribute to the overall aesthetics of the venue but also provide safety and comfort to spectators. In summary, steel billets are indispensable in the construction of stadiums and arenas. They are transformed into various structural and architectural components that provide strength, stability, and durability to the overall structure. By utilizing steel billets, stadiums and arenas can be built to withstand the demands of large crowds, harsh weather conditions, and the test of time.

- Q: How are steel billets used in the production of electrical transmission towers?

- Steel billets play a crucial role in the manufacturing of electrical transmission towers. These billets are semi-finished steel products that are cast into a specific shape and size. When it comes to transmission towers, steel billets are used as raw material to create the tower structures. The process begins by carefully selecting high-quality steel billets and inspecting them for their chemical composition and physical properties. Once the billets meet the required specifications, they undergo heating and are passed through a series of rolling mills to achieve the desired shape and size of the tower sections. To make the steel billets malleable, they are heated to a specific temperature. This heating process reduces internal stresses and enhances the steel's ductility. The heated billets are then shaped into various sections such as angles, channels, and I-beams by passing them through multiple rolling stands. These sections are further cut into appropriate lengths and welded together to form the framework of the transmission tower. The steel billets provide the necessary strength and structural integrity to withstand the weight of the tower and environmental loads like wind and ice. In addition, the use of steel billets ensures excellent corrosion resistance, as steel is known for its durability and longevity. This is crucial for maintaining the reliability and safety of the power transmission infrastructure. In conclusion, steel billets are vital in the production of electrical transmission towers as they provide the raw material necessary for manufacturing the tower structures. Their strength, durability, and corrosion resistance make them an ideal choice for constructing towers that can support transmission lines and ensure efficient and reliable distribution of electricity.

- Q: Can steel billets be used in the production of energy-efficient appliances?

- Yes, steel billets can be used in the production of energy-efficient appliances. Steel is a versatile and durable material that can be formed into various components of appliances, such as shells, frames, and internal structures. When properly designed and manufactured, steel components can contribute to the overall energy efficiency of appliances by ensuring better insulation, heat distribution, and overall performance.

- Q: How are steel billets used in the production of seamless pipes?

- Seamless pipes, which are manufactured without welding or seams, require steel billets as a fundamental component in their production process. Steel billets are rectangular-shaped solid pieces of steel that serve as the raw material for seamless pipe manufacturing. To produce seamless pipes, the initial step is melting steel in a furnace to obtain molten metal. This molten steel is then poured into molds to shape steel billets. These billets are then heated to a specific temperature and pierced using a piercing mill. This mill exerts both axial and radial forces, pushing a pointed mandrel through the center of the billet, resulting in a hollow tube or shell. Following the piercing process, the hollow tube is further elongated and reduced in diameter by a series of rolling mills. These mills apply a combination of rotational and compressive forces to shape the billet into the desired seamless pipe size. The seamless pipe undergoes continuous stretching and rolling until it reaches the desired length and diameter. The utilization of steel billets in the production of seamless pipes holds significant importance for several reasons. Firstly, the billets are crafted from high-quality steel, guaranteeing the strength and durability of the final product. Secondly, the uniformity and consistency of the billets allow for precise shaping and seamless pipe dimensions. Lastly, the solid structure of the billets enables them to withstand the intense forces and temperatures involved in the pipe manufacturing process. In conclusion, steel billets assume a crucial role in the production of seamless pipes. From being melted and molded into billets to being pierced, elongated, and rolled, these billets undergo a series of processes that transform them into high-quality seamless pipes. The use of steel billets ensures the integrity and reliability of seamless pipes, making them suitable for various industrial applications.

- Q: How do steel billets contribute to the manufacturing of consumer goods?

- Steel billets play a crucial role in the manufacturing of consumer goods by serving as the raw material for a wide range of products. These billets are essentially semi-finished steel products that are created through the casting process. They are solid blocks of steel that are heated and then shaped into a specific form, which can vary depending on the intended application. One of the primary ways steel billets contribute to the manufacturing of consumer goods is through their use in the production of various metal parts. These parts can be found in a multitude of products, such as automobiles, appliances, machinery, and furniture. By using steel billets as the starting material, manufacturers can create components that are strong, durable, and resistant to wear and tear. This ensures that the final consumer goods have a long lifespan and can withstand the demands of everyday use. Furthermore, steel billets are often used in the construction industry for the production of structural steel beams, columns, and other building materials. These components are crucial for the construction of infrastructure, residential buildings, commercial complexes, and other structures. Steel's high strength-to-weight ratio makes it an ideal material for these applications, providing the necessary structural support while minimizing the overall weight and cost. In addition to their strength and durability, steel billets also offer versatility in terms of their formability and machinability. This means that they can be easily shaped, welded, and cut into various sizes and designs, allowing manufacturers to tailor the steel components to meet specific consumer needs. This flexibility enables the production of a wide range of consumer goods, from small intricate parts to large complex structures. The use of steel billets in the manufacturing of consumer goods also contributes to sustainability. Steel is a highly recyclable material, and the production of steel products using recycled steel requires significantly less energy and resources compared to using virgin materials. This helps reduce the environmental impact associated with consumer goods production and promotes a more circular economy. Overall, steel billets are a crucial ingredient in the manufacturing of consumer goods. Their strength, durability, versatility, and recyclability make them an ideal material choice for producing a wide range of products that meet the needs and expectations of consumers.

- Q: Refinery carbon 3 is propane, then carbon four carbon five is what name ah?.What are they used for?

- Carbon four is butane, C4H10 carbon five is pentane C5H12

- Q: How are steel billets used in the manufacturing of hydraulic equipment?

- Steel billets are an essential component in the manufacturing process of hydraulic equipment. These billets, which are essentially semi-finished steel forms, play a crucial role in the production of hydraulic components such as cylinders, valves, and pumps. Firstly, steel billets are carefully selected based on their composition and quality. The properties of the steel, such as its strength, ductility, and resistance to corrosion, are important considerations in ensuring the durability and performance of hydraulic equipment. Once the suitable steel billets are obtained, they undergo a series of manufacturing processes to transform them into the desired hydraulic components. For example, the billets may be heated and then forged or extruded to shape them into cylinders or valve bodies. This shaping process helps to achieve the required dimensions, smooth surfaces, and structural integrity. In addition to shaping, steel billets may also undergo machining operations, such as drilling or milling, to create precise holes and intricate features on the hydraulic components. This ensures proper fluid flow and functionality of the equipment. Furthermore, steel billets can be heat-treated to enhance their mechanical properties. Annealing, quenching, or tempering processes may be applied to achieve specific hardness, toughness, or elasticity characteristics, depending on the requirements of the hydraulic equipment. Overall, steel billets serve as the raw material for the manufacturing of hydraulic equipment, providing the necessary strength, durability, and versatility required for these critical components. Their careful selection, shaping, machining, and heat treatment contribute to the production of high-quality hydraulic equipment that can withstand the demanding conditions and pressures of various industrial applications.

- Q: What are the common applications of stainless steel billets?

- Due to their exceptional properties and versatility, stainless steel billets find widespread use in various industries. Some common applications of stainless steel billets include: 1. Construction: Extensively used in the construction industry for structural purposes, stainless steel billets manufacture beams, columns, and other load-bearing components due to their high strength and corrosion resistance. 2. Automotive Industry: The automotive industry utilizes stainless steel billets to manufacture components like exhaust systems, engine parts, and suspension components. The high temperature and corrosion resistance of stainless steel make it an ideal choice for these applications. 3. Aerospace Industry: In the aerospace industry, stainless steel billets manufacture critical components such as aircraft frames, landing gear, and engine parts. Stainless steel's high strength-to-weight ratio and resistance to extreme temperatures make it a preferred material in this sector. 4. Oil and Gas Industry: The oil and gas industry widely employs stainless steel billets due to their excellent corrosion resistance. They manufacture pipes, fittings, valves, and other equipment that come in contact with corrosive fluids or gases. 5. Food Processing Industry: The hygienic properties and resistance to corrosion caused by food and cleaning agents make stainless steel billets extensively used in the food processing industry. Equipment like storage tanks, conveyors, and processing machinery are manufactured using stainless steel billets. 6. Medical and Pharmaceutical Industry: The medical and pharmaceutical industry utilizes stainless steel billets for manufacturing surgical instruments, implants, and equipment. Stainless steel's biocompatibility and sterilization capabilities make it suitable for these critical applications. 7. Marine Industry: In the marine industry, stainless steel billets are used to manufacture components such as ship hulls, propellers, and fittings. The corrosion resistance of stainless steel is crucial in the harsh saltwater environment. 8. Power Generation Industry: Power plants employ stainless steel billets for manufacturing boilers, heat exchangers, and turbine components. The high-temperature and corrosion resistance properties of stainless steel make it suitable for these demanding applications. In conclusion, stainless steel billets possess exceptional properties such as strength, corrosion resistance, and temperature resistance, allowing them to have a wide range of applications across industries. From construction and automotive to aerospace and medical sectors, stainless steel billets play a vital role in manufacturing critical components and equipment.

- Q: Can steel billets be used for making architectural structures?

- Yes, steel billets can be used for making architectural structures. Steel billets are commonly used as a raw material in the construction industry for various applications including the fabrication of beams, columns, and other structural components. The high strength and durability of steel make it an ideal choice for architectural structures, providing stability and structural integrity to buildings.

- Q: What is Alfa carbon? What is beta carbon?

- Alfa is directly connected with the functional groups of carbon atoms of carbon atoms, such as CH3CH2COOH CH2 in which methylene propionate is Alfa carbon carbon carbon atom is the beta carbon atom is directly connected with the functional groups and the connection of the carbon (around Kazakhstan), such as the CH3CH2COOH CH3 propionic acid methyl carbon is the beta carbon

Send your message to us

Prime Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords