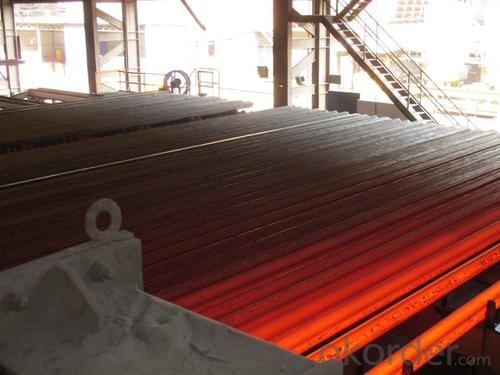

Prime square alloy steel billet 80mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime square alloy steel billet 80mm Q235

Description of Prime square alloy steel billet 80mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime square alloy steel billet 80mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime square alloy steel billet 80mm Q235

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime square alloy steel billet 80mm Q235

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime square alloy steel billet 80mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

we always fix steel produce in container well to make it safe arrive at destination port

we always provide best and professional forward service for our buyer

we always apply 14days free detention for our buyers container in destination

we provide one set After-sales service for our buyer

we provide China inland steel market price report

we help our buyer become number one in local market .

- Q: Can steel billets be used in marine environments?

- Yes, steel billets can be used in marine environments. Steel is a popular choice for various marine applications due to its strength, durability, and corrosion resistance properties. Steel billets, which are semi-finished products, can be further processed into various marine components such as ship hulls, offshore platforms, and marine structures. To withstand the harsh conditions of marine environments including exposure to saltwater, steel used in these applications is typically treated with anti-corrosion coatings or alloys. These protective measures help prevent the corrosion of steel and maintain its structural integrity, ensuring it can withstand the corrosive effects of seawater and other marine elements. Moreover, steel billets can undergo additional processes such as hot rolling, forging, or extrusion to shape them into the desired marine components. These processes further enhance the mechanical properties of the steel, making it suitable for marine applications where high strength and resistance to impact and fatigue are required. Overall, steel billets can be effectively used in marine environments, provided they are properly treated and processed to withstand the corrosive nature of seawater and meet the specific requirements of marine applications.

- Q: What are the potential applications of steel billets in the chemical aftermarket?

- The chemical aftermarket offers a multitude of possibilities for the utilization of steel billets. One significant application of these billets lies in their role in the production of various chemical processing equipment. Reactors, heat exchangers, columns, and other critical components utilized in chemical plants can all be manufactured using steel billets. Furthermore, steel billets are also employed in the construction of storage tanks designed for the safe containment of chemicals. These tanks must possess qualities such as strength, durability, and resistance to corrosion, which can be achieved through the use of steel billets. Moreover, steel billets find their purpose in the fabrication of pipelines and piping systems used for the transportation of chemicals. Their exceptional strength, as well as their ability to withstand extreme temperatures and pressures, make them an ideal choice for constructing pipelines capable of handling corrosive and hazardous chemicals. Additionally, steel billets can be shaped and formed into various fittings and flanges, which serve as essential components in chemical systems. These fittings and flanges play a vital role in connecting different sections of piping, valves, and other equipment, thereby ensuring a secure and leak-free operation. To summarize, the potential applications of steel billets in the chemical aftermarket are vast and varied. From the manufacturing of chemical processing equipment to the construction of storage tanks, pipelines, and fittings, steel billets play a crucial role in guaranteeing the safe and efficient operation of chemical facilities.

- Q: What are the different production methods for steel billets?

- There are several different production methods for steel billets, including continuous casting, ingot casting, and direct hot rolling. Continuous casting involves pouring molten steel into a water-cooled mold to form a continuous strand, which is then cut into desired lengths. Ingot casting involves pouring molten steel into individual molds to form solid blocks, which are later reheated and rolled into billets. Direct hot rolling involves passing a large steel ingot through a series of rolling mills to reduce its size and shape it into a billet.

- Q: How are steel billets heat-treated?

- Steel billets are heat-treated using a process called annealing or quenching and tempering. Annealing involves heating the steel billets to a specific temperature and then slowly cooling them down. This process helps to relieve any internal stresses and improve the overall ductility and toughness of the steel. Quenching and tempering, on the other hand, involves heating the steel billets to a high temperature and then rapidly cooling them by immersing them in a quenching medium, such as water or oil. This rapid cooling creates a hard and brittle structure in the steel, which is then tempered by reheating the billets to a lower temperature. This tempering process helps to reduce the brittleness and increase the toughness of the steel billets. The specific heat treatment process used depends on the desired properties and applications of the steel billets.

- Q: What are the common sizes of steel billets?

- The common sizes of steel billets can vary depending on the specific industry and application. However, there are several standard sizes that are commonly used. In the construction industry, the most common sizes of steel billets range from 100mm x 100mm to 200mm x 200mm. These sizes are often used for structural steel fabrication, such as beams, columns, and other load-bearing components. For the manufacturing of automotive parts, the common sizes of steel billets typically range from 150mm x 150mm to 250mm x 250mm. These sizes are commonly used for forging and machining processes to create components like crankshafts, connecting rods, and gears. In the oil and gas industry, larger steel billets are often required for the production of pipes and tubes. The common sizes for this application range from 350mm x 350mm to 500mm x 500mm. These larger billets allow for the production of seamless pipes that can withstand high-pressure environments. It's important to note that these are just general sizes and can vary depending on specific project requirements and regional standards. Additionally, custom sizes can also be produced based on the customer's needs.

- Q: How do steel billets contribute to the manufacturing of marine equipment?

- Steel billets play a crucial role in the manufacturing of marine equipment. These billets are semi-finished products that are used as raw materials in the production of various marine components such as ship hulls, propellers, shafts, and other structural parts. One of the primary reasons steel billets are preferred in the marine industry is their excellent strength and durability. Ships and other marine equipment are subjected to harsh conditions including extreme temperatures, corrosive saltwater, and heavy loads. Steel billets, being made of high-quality steel, possess the necessary strength to withstand these challenging environments, ensuring the long-term reliability and safety of the equipment. Moreover, steel billets provide the flexibility to create complex shapes and designs required in marine equipment manufacturing. The billets can be easily molded and forged into desired shapes, allowing for the creation of intricate components with precise specifications. This versatility enables the production of different marine equipment parts that are essential for the efficient operation of vessels. Another advantage of using steel billets in marine equipment manufacturing is their corrosion resistance. Steel billets can be treated with various protective coatings or alloys to enhance their resistance to corrosion caused by exposure to seawater. This corrosion resistance is vital in preserving the integrity and longevity of marine equipment, ensuring they can withstand the harsh marine environment for extended periods. Furthermore, steel billets offer excellent weldability, making them suitable for the construction and repair of marine equipment. The ability to weld steel billets together allows for the seamless joining of different components, ensuring structural integrity and reducing the risk of failure. This welding capability facilitates the assembly and maintenance of marine equipment, enabling efficient production processes and cost-effective repairs. In summary, steel billets are essential in the manufacturing of marine equipment due to their strength, durability, versatility, corrosion resistance, and weldability. These qualities make steel billets a preferred choice for producing various marine components, ensuring the reliability, safety, and longevity of the equipment in the demanding marine environment.

- Q: What are the properties of alloy steel billets?

- Alloy steel billets are highly sought after in various industries due to their numerous desirable properties. Chief among these is their exceptional strength and toughness, which is attributed to the presence of alloying elements like chromium, nickel, molybdenum, and vanadium. This heightened strength enables the billets to withstand heavy loads and high temperatures, making them ideal for applications that demand resistance to wear and tear. Furthermore, alloy steel billets possess excellent corrosion resistance, rendering them perfect for use in harsh environments or exposure to chemicals. This resistance to corrosion not only extends the lifespan of the billets but also ensures their durability over time. Moreover, alloy steel billets exhibit good machinability, allowing them to be easily shaped, formed, and fabricated into various products or components. This quality facilitates the creation of intricate and complex designs, making them versatile for use in automotive, construction, and manufacturing industries. Another noteworthy property of alloy steel billets is their ability to undergo heat treatment. This process enables the adjustment of their mechanical properties, such as hardness and ductility, to meet specific requirements. Heat treatment enhances the strength and toughness of the billets, making them even more suitable for heavy-duty applications. Lastly, alloy steel billets possess excellent weldability, enabling them to be easily joined together through various welding techniques. This characteristic adds to their versatility and allows for the construction of larger structures or the fabrication of complex assemblies. In conclusion, the properties of alloy steel billets, including strength, corrosion resistance, machinability, heat treatability, and weldability, make them extremely valuable in industries where high performance and durability are crucial.

- Q: What are the main factors that influence the strength of steel billets?

- The main factors that influence the strength of steel billets include the chemical composition of the steel, the heat treatment process, the presence of impurities and alloying elements, the cooling rate during the solidification process, and the mechanical processing and deformation of the billets.

- Q: Can steel billets be used for making jewelry?

- Yes, steel billets can be used for making jewelry, especially for creating unique and bold designs that incorporate an industrial or contemporary aesthetic. However, steel is not as commonly used for jewelry making compared to other materials like gold, silver, or platinum.

- Q: What is the typical composition of a steel billet?

- The specific grade and intended use of a steel billet can cause its typical composition to vary. Nevertheless, in general, a steel billet primarily consists of iron, carbon, and additional alloying elements. Steel's main constituent is iron, which typically accounts for about 98% of its composition. This element provides the material with structural strength and durability. Carbon, the second most significant element, usually ranges from 0.02% to 2.1% and plays a vital role in determining the steel's hardness and strength. Besides iron and carbon, steel billets often incorporate various alloying elements to enhance specific properties. These elements may include manganese, silicon, nickel, chromium, molybdenum, vanadium, and others. Each element contributes to different characteristics, such as corrosion resistance, heat resistance, toughness, or machinability. Moreover, steel billets are frequently produced through processes like continuous casting or hot rolling, which can introduce small amounts of impurities. These impurities, such as sulfur, phosphorus, and oxygen, are typically maintained at very low levels to preserve the desired quality of the steel. In conclusion, the typical composition of a steel billet comprises a combination of iron, carbon, alloying elements, and minor impurities. These components are carefully regulated to achieve the desired mechanical properties and performance for a wide range of applications in industries such as construction, automotive, aerospace, and manufacturing.

Send your message to us

Prime square alloy steel billet 80mm Q235

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords