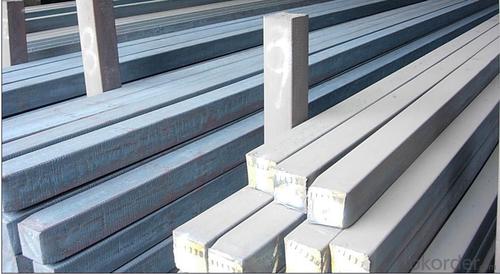

Prime quality square alloy steel billet 115mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime quality square alloy steel billet 115mm Q235

Description of Prime quality square alloy steel billet 115mm Q235

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime quality square alloy steel billet 115mm Q235

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime quality square alloy steel billet 115mm Q235

Construction

Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille

Light industries

Home appliance's case, civil chimney, kitchen utensils

Auto industry

Corrosion resistant parts of cars

Agriculture

Food storage, meat and aquatic products' freezing and processing equipment

Commerce

Equipments to store and transport materials, and packing implements

Specifications of Prime quality square alloy steel billet 115mm Q235

Product | Prime quality square alloy steel billet 115mm Q235 |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime quality square alloy steel billet 115mm Q235

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the safety precautions in handling steel billets?

- To prevent accidents and injuries, it is necessary to adhere to specific safety precautions when handling steel billets. Some of the essential precautions include: 1. Personal Protective Equipment (PPE): Always wear appropriate PPE, such as safety goggles, gloves, steel-toed boots, and protective clothing. This will safeguard against potential hazards like sharp edges, falling objects, and flying debris. 2. Lifting Techniques: Employ proper lifting techniques, such as bending the knees and using the legs to lift. This will help avoid strains or injuries to the back. If the billets are too heavy to lift manually, utilize mechanical lifting equipment like cranes or forklifts. 3. Secure Storage: Ensure that steel billets are stored securely and stably. This will prevent them from toppling or rolling, which can lead to injuries or damage to equipment and infrastructure. To keep the billets organized and secure, employ suitable storage racks, bins, or pallets. 4. Handling Tools: Safely handle steel billets using appropriate tools such as lifting hooks, clamps, or tongs. Avoid using your hands or body to move or reposition the billets, as this can result in pinching, crushing, or cutting injuries. 5. Clear and Well-Defined Work Area: Maintain a work area around the steel billets that is clear and well-defined. This will prevent tripping hazards. Remove any obstructions or debris that could cause slips, trips, or falls. 6. Communication and Training: Ensure that all personnel involved in handling steel billets receive sufficient training in safe handling procedures and are aware of potential hazards. Establish clear communication channels to coordinate movements and actions, especially when using machinery or working in teams. 7. Inspection and Maintenance: Regularly inspect the condition of the steel billets, lifting equipment, and storage racks to identify any potential safety issues. Promptly address any defects, damages, or signs of wear and tear to prevent accidents. 8. Emergency Procedures: Establish emergency procedures and ensure that all personnel are familiar with them. This includes procedures for handling accidents, injuries, spills, or other emergencies that may occur during the handling of steel billets. By adhering to these safety precautions, the risk of accidents and injuries can be minimized, creating a safer working environment for those involved in handling steel billets.

- Q: What is the difference between carbon three plants and carbon four plants?

- The mesophyll cells of carbon three plants are more dispersed, and there are no chloroplasts in bundle sheath cells. Photosynthesis is only carbon three cycle, and the utilization rate of carbon dioxide is low. It usually lives in temperate zone.Four carbon plant mesophyll cells arranged regularly, the formation of two circles of the "ring" and bundle sheath cells, bundle sheath cells have no chloroplast grana, photosynthesis has three carbon cycle and carbon cycle four, higher utilization rate of carbon dioxide, the general life in tropical and subtropical regions.The initial product of CO2 assimilation is not photosynthetic carbon cycle in three carbon compounds 3- phosphoglycerate, but four carbon compounds malic acid or aspartic acid plant.

- Q: What are the different testing methods used for steel billets?

- To ensure the quality and suitability of steel billets for various applications, multiple testing methods are employed. These methods encompass: 1. Visual Inspection: The most straightforward and widely used technique involves visually examining the billets for visible defects like cracks, surface irregularities, or foreign materials. 2. Dimensional Inspection: To meet specific dimensional requirements, the length, width, and height of the billets are measured using calibrated tools, ensuring they adhere to the specified tolerances. 3. Ultrasonic Testing: Detecting internal defects, this non-destructive method employs high-frequency sound waves. By transmitting sound waves into the material and analyzing the reflected waves, flaws or inconsistencies can be identified. 4. Magnetic Particle Inspection: Utilized primarily to detect surface and near-surface defects, this method applies a magnetic field to the billet, followed by the application of a magnetic particle solution. Any cracks or defects cause the particles to accumulate, creating visible indications. 5. Eddy Current Testing: This technique involves passing an alternating current through a probe, generating an electromagnetic field. Placing the probe near the billet's surface allows the detection of defects through changes in electrical conductivity or magnetic permeability, which induce eddy currents. 6. Chemical Analysis: The composition of steel billets, including the percentage of elements like carbon, manganese, and silicon, is determined through chemical analysis. This ensures compliance with the required chemical composition for their intended use. 7. Tensile Testing: By subjecting a sample taken from the billet to tension until it fractures, tensile testing measures mechanical properties such as strength, ductility, and elasticity. The applied force and resulting elongation or deformation provide insights into the billet's mechanical characteristics. These testing methods comprehensively assess steel billets for defects, dimensional accuracy, and material properties. By ensuring adherence to industry standards and meeting specific application requirements, the suitability and quality of the billets are guaranteed.

- Q: What is the role of steel billets in the construction of sports facilities?

- The construction of sports facilities heavily relies on steel billets. These semi-finished steel products serve as the primary raw materials for manufacturing various structural components and equipment needed for sports complexes. One crucial use of steel billets in sports facility construction is for producing steel beams and columns. These structural elements provide the necessary support and stability to ensure athlete and spectator safety. Steel billets are melted and shaped into beams and columns, which then form the framework of the sports facility. Furthermore, steel billets are also utilized in fabricating sports equipment such as goalposts, fencing, and handrails. These components require high strength and durability to withstand the physical demands of the sport and extensive use. By using steel billets, these equipment can be manufactured to meet strength standards while ensuring longevity and safety. Additionally, steel billets play a significant role in constructing seating areas and grandstands within sports facilities. The high load-bearing capacity and structural integrity of steel make it an ideal material for supporting large crowds. By using steel billets, seating areas can withstand heavy loads and provide a safe and comfortable environment for spectators. Moreover, steel billets are instrumental in constructing roofing and façade systems. Steel panels made from these billets offer excellent resistance to weathering, corrosion, and fire, making them suitable for outdoor sports facilities. These panels can be fabricated to provide insulation, protection, and aesthetic appeal, enhancing the overall functionality and appearance of the sports complex. In conclusion, steel billets are vital in sports facility construction. From manufacturing structural elements to producing sports equipment and creating seating and roofing systems, steel billets provide the necessary strength, durability, and safety required for such facilities. Their versatility and reliability make them an indispensable component in the construction process, ensuring that sports complexes meet the highest standards of quality and performance.

- Q: How are steel billets used in the manufacturing of chemical processing equipment?

- The manufacturing process of chemical processing equipment heavily relies on steel billets. These billets act as the primary material that undergoes various transformations to become the final products necessary for chemical processing plants. To begin with, steel billets are crucial for the production of high-quality steel plates. These plates form the structural framework of chemical processing equipment. They are meticulously cut, shaped, and welded together to create vessels, reactors, and storage tanks. The exceptional strength and durability of steel make it the ideal choice for containing corrosive chemicals and withstanding the extreme pressures and temperatures experienced in chemical processing. Not only that, but steel billets also play a vital role in the creation of pipes and fittings used in chemical processing plants. These billets are heated and passed through a series of rollers to form seamless or welded pipes. The resulting pipes are then subjected to further processing and fabrication to meet specific requirements such as corrosion resistance, heat resistance, and pressure ratings. Additionally, steel billets are instrumental in the manufacturing of various components of chemical processing equipment, including valves, flanges, and other fittings. These components are essential for controlling the flow of chemicals, regulating pressure, and connecting different parts of the processing system. Steel billets are machined, forged, or cast to create these components, ensuring their strength, reliability, and resistance against chemical corrosion. To sum up, steel billets are an indispensable part of the manufacturing process for chemical processing equipment. Their versatility, strength, and resistance to corrosion make them the preferred choice for constructing the structural framework, pipes, and fittings needed in chemical processing plants. By utilizing steel billets, manufacturers can guarantee the reliability, safety, and longevity of the equipment used in the chemical industry.

- Q: How are steel billets used in the production of construction components?

- Steel billets are an essential raw material in the production of construction components. They are primarily used in the manufacturing of various structural elements such as beams, columns, and bars that form the framework of buildings and infrastructure projects. The process begins with steel billets, which are semi-finished products made from molten steel that has been cast into rectangular or square shapes. These billets are then further processed and transformed into specific construction components through various manufacturing techniques. One common application of steel billets is in the production of beams, which are essential for supporting the weight of floors, roofs, and walls in buildings. Billets are processed through rolling mills, where they are heated and passed through a series of rollers to shape them into the desired beam profile. This process allows for the production of beams of different sizes and lengths, catering to the unique requirements of each construction project. Steel billets are also used in the production of columns, which provide vertical support to structures. Similarly to beams, billets are processed through rolling mills to obtain the required column shape. The columns are then joined to the beams to form the skeletal framework of the building, providing strength and stability. In addition to beams and columns, steel billets are employed in the production of bars used for reinforcing concrete. These reinforcing bars, commonly known as rebar, are crucial for enhancing the strength and durability of concrete structures. Billets are again processed through rolling mills to create rebar of various diameters and lengths. The rebar is then embedded within the concrete to provide tensile strength, preventing cracking and increasing the overall structural integrity. Overall, steel billets play a vital role in the production of construction components by serving as the starting point for the manufacturing process. They are transformed into beams, columns, and rebar, providing the necessary strength and stability required in the construction of buildings and infrastructure projects.

- Q: How are steel billets used in the production of turbine blades?

- Steel billets are used in the production of turbine blades as raw material. These billets are first forged into the desired shape and then undergo precision machining to achieve the required dimensions and finish. The steel billets provide the strength and durability necessary to withstand the high temperatures and forces experienced by turbine blades during operation.

- Q: How are steel billets used in the production of aerospace components?

- Steel billets play a crucial role in the aerospace industry by serving as the initial material for manufacturing aerospace components. These billets, which are semi-finished steel forms, are either hot-rolled or forged into specific shapes and sizes. Aerospace manufacturers commonly use steel billets to produce critical components like landing gear, engine parts, structural elements, and fasteners. These billets are chosen for their outstanding strength, durability, and resistance to high temperatures and corrosive environments, all of which are vital characteristics for aerospace applications. The production process of aerospace components using steel billets involves several steps. Initially, the billets are heated to a high temperature to make them malleable and easy to work with. Various forming techniques like forging, extrusion, or rolling then shape the billets into the desired forms. These processes guarantee precise shaping and dimensional accuracy, ensuring that the components meet the required specifications and tolerances. After the initial shaping, further processes such as heat treatment, machining, and surface finishing are applied to enhance the mechanical properties and surface quality of the aerospace components. Heat treatment methods like quenching and tempering strengthen the steel, improving its hardness, toughness, and resistance to wear and fatigue. Subsequently, machining processes are utilized to achieve the final shape, size, and surface finish of the components. Once the components are manufactured, they undergo rigorous quality control measures to ensure compliance with the strict standards and regulations of the aerospace industry. Thorough inspections, non-destructive testing, and material analysis are conducted to verify the integrity, performance, and safety of the components. In conclusion, steel billets are indispensable in the production of aerospace components, providing a reliable and robust starting material. The versatility and exceptional mechanical properties of steel make it the preferred choice in the aerospace industry, where reliability and safety are of utmost importance.

- Q: What is the role of steel billets in the manufacturing of storage systems?

- Steel billets play a crucial role in the manufacturing of storage systems as they serve as the raw material for the production of various steel components used in these systems. These billets are heated, rolled, and shaped to create beams, columns, and other structural elements that provide strength and stability to the storage systems. Additionally, steel billets can be further processed to create shelves, racks, and other storage components, ensuring durability and reliability in the overall design.

Send your message to us

Prime quality square alloy steel billet 115mm Q235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords