Prime quality prepainted galvanized steel 715mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

Specifications

Commodity Name: Prepainted Galvanized Steel Coil

Standard: AISI, ASTM, DIN, GB, JIS

Grade: TDC52D+Z

Thickness 0.13-8.0mm

Width:600mm-1350mm

Zinc Coating:275g/m2

Polyester Coating Thickness:Top and Back coating thickness depend by Buyer Requirement.

Polyester Coating Type:2/2,1/2m,1/2.

Polyester Type: Polyester, silicone modified polyester, high durability polyester (HDP), polyvinylidene fluoride (PVDF)

Unit Roll Weight:5-20tons

Place of Origin Shanghai , China (Mainland)

Surface Treatment :Color Coated

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

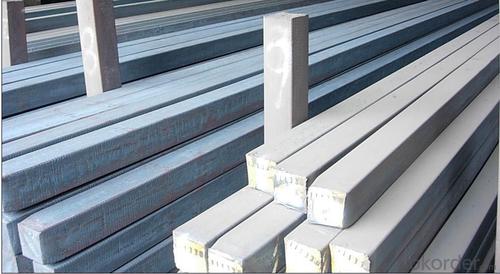

- Q: What are the common defects found in steel billets?

- There are several common defects that can be found in steel billets. These defects can occur during the manufacturing process or due to external factors. One common defect is surface cracks, which can occur due to improper cooling, handling, or excessive stress during rolling or forming. These cracks can weaken the billet and affect its overall strength and integrity. Another common defect is internal voids or inclusions, which can occur due to the presence of impurities or foreign particles in the steel. These voids can create weak spots in the billet and can lead to structural failures or reduced mechanical properties. Misalignment or misshaping is another defect that can occur during the cooling or forming process. This defect can result in uneven thickness or dimensions, which can compromise the billet's performance and suitability for its intended application. In addition, excessive segregation of alloying elements can occur, leading to uneven distribution of properties within the billet. This can result in inconsistent mechanical properties and reduced overall quality. Lastly, surface defects such as scale, pitting, or surface imperfections can also be found in steel billets. These defects can occur due to improper handling, storage, or exposure to harsh environments. While these defects may not affect the structural integrity of the billet, they can impact the surface finish and aesthetics of the final product. Overall, it is essential to identify and address these common defects in steel billets to ensure the production of high-quality and reliable steel products. Regular inspections, quality control measures, and proper handling and storage techniques can help minimize and prevent these defects.

- Q: How has the demand for steel billets changed over time?

- The demand for steel billets has experienced fluctuations over time, influenced by various factors. Historically, there has been a steady growth in the demand for steel billets due to the increasing industrialization and urbanization worldwide. As construction and infrastructure projects expanded, the demand for steel billets, which serve as the raw material for various steel products, also increased. However, the demand for steel billets has not been immune to economic cycles. During periods of economic downturns, such as the global financial crisis in 2008, the demand for steel billets declined as construction and manufacturing activities slowed down. This led to a surplus of steel billets in the market, resulting in decreased prices and reduced demand from steel mills. In recent years, the demand for steel billets has been influenced by global trends and geopolitical factors. The increasing focus on sustainable development and environmental concerns has led to a growing demand for green construction materials, including steel produced from recycled sources. This has prompted steel manufacturers to adapt their production processes to meet these demands and ensure the availability of environmentally friendly steel billets. Moreover, geopolitical factors such as trade disputes and tariffs have also impacted the demand for steel billets. The imposition of tariffs on steel imports by certain countries has led to a decrease in demand for imported steel billets, while simultaneously increasing demand for domestically produced steel billets. Furthermore, the COVID-19 pandemic had a significant impact on the demand for steel billets. Lockdowns, travel restrictions, and disrupted supply chains caused a decline in construction activities and manufacturing output, leading to a decrease in demand for steel billets. However, as economies recover and governments implement stimulus measures to boost infrastructure projects, the demand for steel billets is expected to gradually rebound. In summary, the demand for steel billets has experienced fluctuations over time, influenced by economic cycles, global trends towards sustainability, geopolitical factors, and the COVID-19 pandemic. The long-term growth in demand for steel billets remains closely tied to construction and infrastructure development, making it vital for steel manufacturers to adapt to changing demands and market conditions.

- Q: How are steel billets unloaded at the destination?

- Steel billets are typically offloaded at the destination using different techniques depending on the available infrastructure and equipment. One commonly used approach involves the utilization of cranes or forklifts that are equipped with lifting attachments. These machines have the capability to lift and move the heavy steel billets from the transport vehicle to the designated storage area or processing facility. In certain situations, a specialized unloading facility like a rail yard or port may be utilized. In these cases, cranes or gantry systems are often employed to efficiently transfer the steel billets from rail cars or shipping containers onto trucks or storage areas. This method allows for a more streamlined unloading process, especially when dealing with large quantities of steel billets. Another method that is sometimes employed involves the use of conveyor belts or rollers. This method proves particularly effective when unloading steel billets from a container or truck where they are arranged in a row. The conveyor belt or roller system permits a continuous unloading process, with the billets being moved along the conveyor to the desired location. Irrespective of the method employed, safety precautions are always implemented during the unloading process to ensure the well-being of workers and the prevention of any damage to the steel billets. These precautions may encompass the use of proper lifting techniques, securing the billets during transportation, and the wearing of appropriate personal protective equipment. In summary, the unloading of steel billets at the destination necessitates meticulous planning, efficient machinery, and adherence to safety protocols to ensure a smooth and successful operation.

- Q: How are steel billets used in the manufacturing of fasteners?

- Steel billets are an essential component in the manufacturing of fasteners. Fasteners are devices used to join or secure two or more objects together. They are commonly found in various industries such as automotive, construction, and manufacturing. In the production of fasteners, steel billets serve as the raw material. A steel billet is a semi-finished product that typically has a square or rectangle cross-section. It is created through a process called casting, where molten steel is poured into a mold and allowed to cool and solidify. Once the steel billets are obtained, they undergo a series of manufacturing processes to transform them into fasteners. These processes include hot rolling, cold drawing, and machining. Hot rolling is the initial step, where the steel billets are heated to high temperatures and passed through a set of rollers. This process helps shape the billets into long, cylindrical bars or rods of the desired diameter. Next, the hot-rolled bars are subjected to a process called cold drawing. In this process, the bars are pulled through a series of dies to reduce their diameter and improve their surface finish. Cold drawing also helps enhance the mechanical properties of the steel, making it stronger and more durable. Finally, the steel bars are machined to create the specific fastener design. This involves cutting, threading, and forming the bars to produce bolts, screws, nuts, or other types of fasteners. The machined fasteners are then subjected to heat treatment processes such as quenching and tempering to further enhance their strength and hardness. In summary, steel billets are crucial in the manufacturing of fasteners as they provide the raw material that undergoes various transformation processes. Through hot rolling, cold drawing, and machining, steel billets are shaped into the desired form, resulting in high-quality fasteners that meet industry standards.

- Q: What is the average lifespan of a steel billet in a structural application?

- Several factors can greatly affect the average lifespan of a steel billet in a structural application. These factors encompass the quality of the steel utilized, the specific structural application, the environmental conditions, and the level of maintenance and care given to the structure. Steel is generally acknowledged for its durability and longevity, making it a popular choice for structural applications. When designed, constructed, and maintained properly, a steel billet can have a lifespan ranging from several decades to over a century. However, it is important to acknowledge that certain factors can significantly impact the lifespan of a steel billet. For instance, exposure to harsh environmental conditions like extreme temperatures, corrosive substances, or high levels of humidity can expedite the steel's deterioration and decrease its lifespan. Similarly, the structural application itself plays a vital role in determining the lifespan of a steel billet. Structures subjected to heavy loads, frequent vibrations, or dynamic stresses may experience accelerated deterioration and necessitate more frequent maintenance or replacement. Finally, the quality of the steel used also affects the lifespan of a steel billet. Higher quality steels, such as those with exceptional corrosion resistance or higher tensile strength, generally have longer lifespans compared to lower grade steels. To accurately ascertain the average lifespan of a steel billet in a specific structural application, it is advisable to consult with structural engineers, manufacturers, or industry experts. These professionals can evaluate the specific conditions and provide a more precise estimate based on their expertise and knowledge of the particular project.

- Q: What are the main factors affecting the microstructure of steel billets?

- The main factors affecting the microstructure of steel billets include the composition of the steel, the cooling rate during solidification, the presence of impurities or alloying elements, and the heat treatment processes applied.

- Q: What is the role of steel billets in the manufacturing of fasteners?

- Fasteners, which are crucial components used to connect objects and provide stability and strength, rely heavily on steel billets in their manufacturing process. Acting as semi-finished products, steel billets serve as the starting point for fastener production. To make the steel billets malleable, the first step in the manufacturing process involves heating them to a specific temperature of approximately 1200-1300 degrees Celsius. This heating process facilitates easier shaping and manipulation during subsequent stages. Once the billets are heated, they undergo shaping by passing through a series of dies. These dies exert significant pressure to mold the billets into the desired form of the fastener. Designed with precise dimensions and shapes for each type of fastener, such as bolts, screws, or nuts, the dies play a key role in the shaping process. The deformation and compression experienced by the steel billets during shaping result in the basic structure and form of the fastener. The pressure applied by the dies ensures that the fasteners possess the necessary strength and durability to withstand the forces they will encounter in their intended applications. Moreover, steel billets are selected for fastener manufacturing due to their inherent properties. Steel exhibits exceptional strength, toughness, and corrosion resistance, making it an ideal material for fasteners. By starting with high-quality steel billets, the resulting fasteners will inherit these desirable attributes, guaranteeing reliability and longevity after installation. In conclusion, the significance of steel billets in fastener production cannot be overstated. Serving as the raw material, they undergo shaping and deformation to ultimately acquire the desired fastener shape. The use of steel billets ensures that the resulting fasteners possess the required strength, durability, and corrosion resistance for their intended applications.

- Q: What are the different types of steel billet surface treatment defects?

- Some common types of steel billet surface treatment defects include pitting, scaling, decarburization, scratches, and cracks.

- Q: What are the potential risks associated with steel billet production?

- There are several potential risks associated with steel billet production. Firstly, the production process involves the use of high temperatures and molten metal, which can pose a risk of burns and fire hazards. Operators and workers must exercise caution while handling the equipment and ensure proper safety protocols are followed to prevent accidents. Secondly, the raw materials used in steel billet production, such as iron ore and coal, can contain impurities that may release harmful gases and particulate matter during the production process. These emissions can pose health risks to workers and nearby communities if not properly controlled and mitigated. Additionally, the machinery and equipment used in steel billet production, including furnaces and rolling mills, can pose mechanical hazards if not properly maintained or operated. Accidents such as equipment malfunctions or material failures can result in injuries to workers and damage to the production facility. Furthermore, the steel industry is energy-intensive, requiring significant amounts of electricity and fossil fuels for the production process. This reliance on non-renewable energy sources contributes to greenhouse gas emissions and climate change. Efforts should be made to minimize the environmental impact through energy-efficient practices and the adoption of cleaner technologies. Lastly, the transportation of steel billets from the production facility to the next stage in the supply chain can present risks. Handling and moving heavy steel billets require proper lifting and securing techniques to prevent accidents and injuries during loading, unloading, and transportation. To mitigate these risks, it is crucial for steel billet producers to prioritize safety measures, including regular equipment inspections, proper training for workers, implementation of environmental controls, adherence to safety regulations, and continuous improvement in operational practices.

- Q: What are the potential applications of steel billets in the oil and gas sector?

- Steel billets have numerous potential applications in the oil and gas sector. They can be used to manufacture various critical components such as pipes, valves, and fittings, which are essential for the transportation, processing, and storage of oil and gas. Steel billets also find use in the construction of offshore platforms and drilling equipment due to their high strength and durability. Additionally, they can be utilized in the fabrication of pressure vessels, heat exchangers, and other infrastructure required for oil refining and petrochemical processes. Overall, steel billets play a crucial role in ensuring the safety, reliability, and efficiency of operations in the oil and gas industry.

Send your message to us

Prime quality prepainted galvanized steel 715mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords