Prime quality prepainted galvanized steel 710mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

Specifications

Commodity Name: Prepainted Galvanized Steel Coil

Standard: AISI, ASTM, DIN, GB, JIS

Grade: TDC52D+Z

Thickness 0.13-8.0mm

Width:600mm-1350mm

Zinc Coating:275g/m2

Polyester Coating Thickness:Top and Back coating thickness depend by Buyer Requirement.

Polyester Coating Type:2/2,1/2m,1/2.

Polyester Type: Polyester, silicone modified polyester, high durability polyester (HDP), polyvinylidene fluoride (PVDF)

Unit Roll Weight:5-20tons

Place of Origin Shanghai , China (Mainland)

Surface Treatment :Color Coated

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

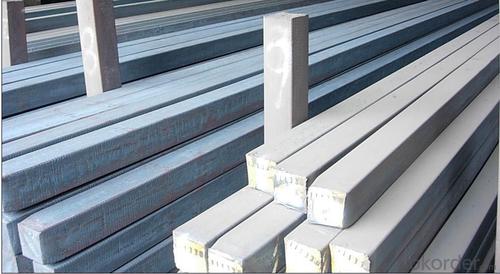

- Q: How are steel billets labeled for identification purposes?

- To identify steel billets, a combination of alphanumeric codes and markings are utilized. These labels contain vital data regarding the billet's composition, size, and other significant particulars. The most prevalent approach to label steel billets involves directly stamping or engraving the necessary information onto the billet's surface. This includes details like steel grade, heat number, lot number, and the manufacturer's symbol or logo. These markings are typically made using durable and legible industrial-grade ink or via electrochemical etching, ensuring their resilience even in harsh environments. Additionally, steel billets may also carry identification tags or labels that offer additional information which cannot be easily engraved or stamped. These tags or labels may feature barcodes, QR codes, or RFID tags, allowing for quick access to relevant information through specialized equipment. By employing these labeling methods, steel billets can be easily identified, tracked, and monitored throughout their lifespan. This ensures effective quality control, inventory management, and efficient production processes within the steel industry.

- Q: What are the main factors that affect the competitiveness of steel billets manufacturers?

- The main factors that affect the competitiveness of steel billet manufacturers include cost of production, quality of products, technological advancements, availability of raw materials, economies of scale, market demand, pricing strategies, and competitiveness of rival manufacturers.

- Q: What are the main factors affecting the metallurgical properties of steel billets?

- There are several main factors that affect the metallurgical properties of steel billets. These factors include the composition of the steel, the heat treatment applied, the presence of impurities, and the cooling rate. The composition of the steel plays a crucial role in determining its metallurgical properties. The amount of carbon, as well as the presence of other alloying elements such as manganese, chromium, and nickel, can significantly impact the steel's strength, hardness, and ductility. Different compositions can also affect the steel's ability to resist corrosion or exhibit magnetic properties. Heat treatment is another important factor that affects the metallurgical properties of steel billets. This process involves heating the steel to a specific temperature and then cooling it at a controlled rate. Heat treatment can alter the microstructure of the steel, which in turn affects its hardness, toughness, and overall mechanical properties. Different heat treatment methods, such as annealing, quenching, and tempering, can be applied to achieve desired metallurgical properties. Impurities present in the steel can also influence its metallurgical properties. Common impurities include sulfur, phosphorus, and oxygen. These impurities can negatively impact the steel's mechanical properties, such as reducing its strength and ductility. Therefore, the level of impurities needs to be minimized to ensure the desired metallurgical properties. Lastly, the cooling rate during the solidification process plays a crucial role in determining the microstructure and properties of the steel billets. Rapid cooling, such as in the case of quenching, can result in a fine-grained microstructure, which enhances the steel's strength and hardness. On the other hand, slow cooling, such as during annealing, can lead to a coarse-grained microstructure, which improves the steel's ductility and toughness. In conclusion, the main factors affecting the metallurgical properties of steel billets include the composition of the steel, the heat treatment applied, the presence of impurities, and the cooling rate. These factors are interrelated and need to be carefully controlled to achieve the desired properties for different applications.

- Q: What are the common sizes of steel billets used in construction?

- The common sizes of steel billets used in construction can vary depending on the specific project and requirements. However, there are several standard sizes that are commonly used in the construction industry. These sizes typically range from 100 mm (4 inches) to 200 mm (8 inches) in width and 100 mm (4 inches) to 300 mm (12 inches) in height. The length of the billets can also vary, but they are often around 6 meters (20 feet) long. These standard sizes are widely available and easily accessible, making them a popular choice for construction projects. However, it is important to note that the actual sizes of steel billets used in construction can be customized based on the specific needs and engineering requirements of a particular project.

- Q: What are the properties of alloy steel billets?

- Alloy steel billets are highly sought after in various industries due to their numerous desirable properties. Chief among these is their exceptional strength and toughness, which is attributed to the presence of alloying elements like chromium, nickel, molybdenum, and vanadium. This heightened strength enables the billets to withstand heavy loads and high temperatures, making them ideal for applications that demand resistance to wear and tear. Furthermore, alloy steel billets possess excellent corrosion resistance, rendering them perfect for use in harsh environments or exposure to chemicals. This resistance to corrosion not only extends the lifespan of the billets but also ensures their durability over time. Moreover, alloy steel billets exhibit good machinability, allowing them to be easily shaped, formed, and fabricated into various products or components. This quality facilitates the creation of intricate and complex designs, making them versatile for use in automotive, construction, and manufacturing industries. Another noteworthy property of alloy steel billets is their ability to undergo heat treatment. This process enables the adjustment of their mechanical properties, such as hardness and ductility, to meet specific requirements. Heat treatment enhances the strength and toughness of the billets, making them even more suitable for heavy-duty applications. Lastly, alloy steel billets possess excellent weldability, enabling them to be easily joined together through various welding techniques. This characteristic adds to their versatility and allows for the construction of larger structures or the fabrication of complex assemblies. In conclusion, the properties of alloy steel billets, including strength, corrosion resistance, machinability, heat treatability, and weldability, make them extremely valuable in industries where high performance and durability are crucial.

- Q: What are the main challenges in the marketing of steel billets?

- There are several factors that contribute to the main challenges faced in marketing steel billets. To begin with, the highly competitive nature of the steel industry is a major hurdle. The market is saturated with numerous steel manufacturers and suppliers worldwide, making it difficult for companies to stand out and maintain a strong presence. In addition, fluctuations in global demand and supply of steel pose significant challenges. Steel billets are primarily used as raw material in industries like construction, automotive, and manufacturing. Any changes in these industries' demand directly affect the demand for steel billets. Therefore, marketing strategies must be adaptable and responsive to market dynamics in order to secure a stable customer base. Pricing is also a critical challenge. Steel billets are subject to price volatility due to factors such as raw material costs, energy prices, and global economic conditions. Companies must constantly analyze these factors to set competitive prices while ensuring profitability. Furthermore, a thorough understanding of the target market's needs and preferences is necessary for effective marketing. Different industries may require specific qualities and specifications in their billets, such as size, composition, or surface finish. To meet these requirements, companies must invest in research and development and effectively communicate the advantages of their products to potential customers. Establishing and maintaining strong relationships with customers is another challenge. Steel billets are typically sold through long-term contracts, relying on trust and reliability. Consistent quality, on-time delivery, and excellent customer service are essential for building and nurturing these relationships. Lastly, environmental sustainability has emerged as a challenge in the marketing of steel billets. With increasing environmental regulations and growing consumer awareness, companies need to position themselves as environmentally responsible and promote sustainable practices throughout their value chain. To conclude, marketing steel billets presents challenges related to intense competition, demand-supply dynamics, pricing, market understanding, customer relationships, and environmental sustainability. Overcoming these challenges requires strategic planning, continuous adaptation, and a customer-centric approach.

- Q: What is the active carbon. What is the difference with the charcoal?

- Activated carbon activated carbon after activation of the solid carbon black porous. A general powder, granular or pellet, carbon as a main component, also containing a small amount of oxygen, hydrogen, nitrogen, sulfur and chlorine. The early production of activated carbon as raw materials for wood, hard shell or animal bone, later used by coal production method a: the steam and gas activation method. The use of water vapor or carbon dioxide at 850 ~ 900 C carbon activation.

- Q: What are the different types of defects that can occur in steel billets?

- There are several types of defects that can occur in steel billets. These defects can occur during the manufacturing process or as a result of external factors. Some of the common types of defects include: 1. Surface defects: These defects occur on the outer surface of the billet and can include scratches, pits, scabs, scale, and cracks. Surface defects can be caused by handling, improper cooling, or contamination during manufacturing. 2. Internal defects: These defects occur within the body of the billet and are not visible on the surface. They can include voids, porosity, inclusions, and segregation. Internal defects can be caused by improper solidification, improper casting, or impurities in the steel. 3. Dimensional defects: These defects occur when the billet does not meet the desired dimensions or tolerances. Dimensional defects can include variations in length, width, thickness, or straightness. These defects can be caused by improper rolling, uneven cooling, or misalignment of the equipment. 4. Mechanical defects: These defects affect the mechanical properties of the steel billet. They can include improper grain structure, low hardness, brittleness, or poor toughness. Mechanical defects can occur due to improper heat treatment, incorrect alloy composition, or inadequate rolling processes. 5. Weld defects: In case of welded billets, defects related to the welding process can occur. These defects can include lack of fusion, incomplete penetration, porosity, or cracks in the weld zone. Weld defects can be caused by improper welding parameters, inadequate preparation, or contamination during the welding process. It is important to detect and address these defects to ensure the quality and integrity of the steel billets. Various inspection techniques such as visual inspection, ultrasonic testing, magnetic particle testing, or radiographic testing can be employed to identify and classify these defects.

- Q: What are the different types of steel billet quality control tests?

- There are several types of steel billet quality control tests, including dimensional checks, chemical composition analysis, surface inspection, mechanical property testing, and non-destructive testing.

- Q: After processing to the color coating board, is there a fare increase of 1000?The price of galvanized coil is about +350 per ton of cold-rolled steel at present What about the cost of billet to cold rolling?What is the final cost of making the color coated sheet? How do you figure that?

- The cost of billet to cold rolling is about 1000Galvanized to color coated sheet costs vary greatly, generally around 300, a high of 500

Send your message to us

Prime quality prepainted galvanized steel 710mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords