Prime quality prepainted galvanized steel 700mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Construction building material galvanized color prepainted cold

rolled steel coil

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and

a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip

Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows:

polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application:

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

Specifications

Commodity Name: Prepainted Galvanized Steel Coil

Standard: AISI, ASTM, DIN, GB, JIS

Grade: TDC52D+Z

Thickness 0.13-8.0mm

Width:600mm-1350mm

Zinc Coating:275g/m2

Polyester Coating Thickness:Top and Back coating thickness depend by Buyer Requirement.

Polyester Coating Type:2/2,1/2m,1/2.

Polyester Type: Polyester, silicone modified polyester, high durability polyester (HDP), polyvinylidene fluoride (PVDF)

Unit Roll Weight:5-20tons

Place of Origin Shanghai , China (Mainland)

Surface Treatment :Color Coated

Manufacture Progress:HRC-CRC-GALVANIZED-COLOR COATED

Application : Construction, electrical, transportation, steel plant, composite board plant, steel tile factory

Payment & Shipping Terms:T/T ,L/C, and FOB CHINA

Minimum Order Quantity: 25Tons

Packge Type: Moisture-proof paper inner,Steel outside,Bundle by steel rope.

Package in Container : Wood as a foot pad, wire rope reinforcement,PPGI steel coil tied together by steel rope.

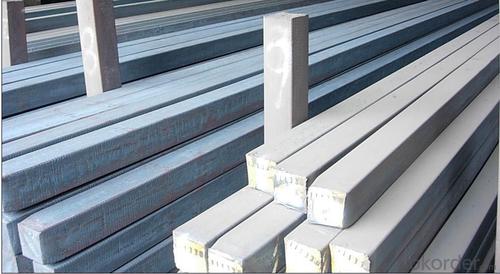

- Q: How do steel billets contribute to the overall cost-effectiveness of a structure?

- Steel billets contribute to the overall cost-effectiveness of a structure due to their versatility and efficiency in construction. These pre-formed, semi-finished steel products can be easily shaped and transformed into various components, reducing the need for extensive machining and fabrication processes. Their strength and durability ensure long-term stability and low maintenance costs, while their high recyclability promotes sustainability and reduces material waste. Additionally, the standardized sizes and consistent quality of steel billets facilitate efficient production and shorter construction timelines, ultimately leading to cost savings for building projects.

- Q: How do steel billets contribute to the manufacturing of marine gear?

- Steel billets play a crucial role in the manufacturing of marine gear due to their unique characteristics and properties. Marine gear includes various components such as propeller shafts, gears, and bearings, which require high strength and resistance to corrosion and wear. Steel billets, which are semi-finished metal forms, serve as the starting material for the manufacturing process. They are typically made from carbon or alloy steel and are shaped into long, rectangular bars. These billets are then further processed to create the specific marine gear components. The high strength of steel billets makes them ideal for marine gear manufacturing as they can withstand the heavy loads and intense pressures experienced in marine environments. This strength ensures the durability and reliability of the gear components, preventing failures and enhancing safety. Corrosion resistance is another critical factor in marine gear manufacturing. Steel billets can be made from stainless steel, which contains chromium and other alloying elements that form a protective layer on the surface, preventing rust and corrosion caused by exposure to saltwater. This corrosion resistance is vital for marine gear as it ensures the longevity and performance of the components in harsh marine conditions. Furthermore, steel billets can be heat-treated to improve their mechanical properties, such as hardness, toughness, and wear resistance. This heat treatment process involves heating the billets to specific temperatures and then cooling them rapidly or slowly, depending on the desired properties. Heat-treated steel billets provide the necessary hardness and wear resistance required for gears, shafts, and bearings to withstand the constant friction and stress encountered in marine applications. In conclusion, steel billets contribute significantly to the manufacturing of marine gear by providing the required strength, corrosion resistance, and mechanical properties. They serve as the foundation material for creating durable and reliable components that can withstand the challenging conditions of the marine environment.

- Q: What are the different methods of steel billet surface painting?

- There are several methods of steel billet surface painting, including spray painting, powder coating, electrostatic coating, and dip coating. Spray painting involves using compressed air or a sprayer to apply a liquid paint to the surface of the billet. Powder coating involves applying a dry powder to the surface, which is then heated to create a durable and protective coating. Electrostatic coating uses an electric charge to attract the paint particles to the billet surface, creating an even and uniform coating. Dip coating involves immersing the billet in a tank of paint, allowing the paint to adhere to the surface. Each method has its own advantages and is chosen based on factors such as the desired finish, cost, and environmental considerations.

- Q: Can steel billets be used in the production of energy-efficient appliances?

- Yes, steel billets can be used in the production of energy-efficient appliances. Steel is a versatile material that is commonly used in the manufacturing of appliances due to its strength and durability. Energy-efficient appliances are designed to consume less energy while performing their intended functions, thereby reducing energy consumption and greenhouse gas emissions. Steel billets can be processed and transformed into various components of energy-efficient appliances such as the outer shells, structural supports, and internal parts. The use of steel in these appliances ensures their longevity and reliability, contributing to their overall energy efficiency. Additionally, steel is a highly recyclable material, meaning that it can be reused or repurposed for other applications at the end of an appliance's life cycle. Recycling steel helps to conserve energy and reduce waste, further supporting the goal of energy efficiency. In summary, steel billets can indeed be utilized in the production of energy-efficient appliances. The strength, durability, and recyclability of steel make it an ideal material choice for manufacturing energy-efficient appliances that contribute to a more sustainable future.

- Q: How do steel billets contribute to the construction industry?

- Steel billets are a crucial component in the construction industry for several reasons. Firstly, they serve as the raw material for the production of various steel products used in construction, such as beams, columns, and reinforcement bars. These products provide structural support and integrity to buildings and infrastructure projects. Steel billets are also essential for the manufacturing of precast concrete elements, which are widely used in construction. Pre-stressed concrete beams, for example, are reinforced with steel billets to enhance their strength and durability. This allows for the construction of larger and more complex structures, such as bridges, stadiums, and high-rise buildings. Moreover, steel billets play a vital role in the fabrication of steel pipes and tubes, which are extensively used in the construction of water supply systems, sewage lines, and gas pipelines. These pipes offer a reliable and efficient means of transporting fluids and gases, ensuring the proper functioning of various infrastructure networks. In addition to their structural applications, steel billets also contribute to the construction industry through their recyclability. Steel is one of the most recycled materials globally, and steel billets can be melted down and reused multiple times without any loss in quality. This not only reduces the demand for virgin steel production but also minimizes environmental impact and waste generation. Overall, steel billets are indispensable in the construction industry due to their versatility, strength, and recyclability. They serve as the backbone for the production of various steel products and play a crucial role in the construction of durable and sustainable buildings and infrastructure projects.

- Q: What are the main factors that influence the strength of steel billets?

- The strength of steel billets is impacted by various factors, including the chemical composition, heat treatment, and microstructure of the steel. The chemical composition plays a significant role in determining the strength of steel billets. Alloying elements like carbon, manganese, silicon, and chromium can enhance strength by forming solid solutions or precipitates that increase hardness and tensile strength. It is crucial to control impurity levels and maintain the desired balance of alloying elements to achieve the desired strength properties. Heat treatment is another important factor that affects the strength of steel billets. This process involves heating the steel to a specific temperature and then cooling it at a controlled rate. It significantly impacts the microstructure of the steel, which ultimately influences its strength. For example, quenching and tempering can result in the formation of desired microstructures like martensite or bainite, which enhance strength and toughness. The microstructure of steel billets also plays a crucial role in determining their strength. The arrangement of crystal grains and the presence of different phases within the steel greatly influence its mechanical properties. Fine-grained structures generally exhibit higher strength due to a greater number of grain boundaries, which inhibit dislocation movement and enhance strength. Additionally, the presence of specific microstructural features like precipitates or second-phase particles can contribute to the strength of steel billets. Other factors such as the manufacturing process, cooling rate during solidification, and mechanical working (such as rolling or extrusion) can also affect the strength of steel billets. These factors impact grain size, grain boundary density, and defect concentration, all of which influence the mechanical properties of the steel. In conclusion, the strength of steel billets is influenced by the chemical composition, heat treatment, and microstructure of the steel. These factors can be carefully controlled and optimized to achieve the desired strength properties for various applications.

- Q: How do steel billets contribute to the manufacturing of electrical appliances?

- Steel billets play a vital role in the manufacturing of electrical appliances by providing a strong and durable material for various components. Electrical appliances, such as refrigerators, washing machines, and air conditioners, require sturdy structures to withstand constant usage and external forces. Steel billets, which are semi-finished metal products, are used as a raw material in the manufacturing process to create these robust structures. Firstly, steel billets are forged or rolled into different shapes and sizes to create the frames, chassis, and housing of electrical appliances. These components provide the necessary support and protection for the internal parts of the appliances. The strength and stability of steel make it an ideal choice for withstanding the weight and vibrations generated during the operation of electrical appliances. Additionally, steel billets are used to fabricate the motor cores and transformer cores in electrical appliances. Motor cores are essential for converting electrical energy into mechanical energy, while transformer cores are responsible for regulating the voltage in electrical circuits. Steel's magnetic properties, such as high electrical conductivity and low hysteresis loss, make it an excellent choice for these applications, ensuring efficient energy conversion and transmission. Moreover, steel billets are utilized to manufacture heating elements and electrical contacts in appliances like stoves, ovens, and switches. These components require materials that can withstand high temperatures, resist corrosion, and provide excellent electrical conductivity. Steel billets are often alloyed with other metals, such as nickel or chromium, to enhance these properties, making them highly suitable for such applications. In conclusion, steel billets contribute significantly to the manufacturing of electrical appliances by providing a durable and versatile material for various components. The strength, stability, and magnetic properties of steel make it an essential raw material for creating the frames, motor cores, transformer cores, heating elements, and electrical contacts used in these appliances. Thanks to steel billets, electrical appliances can perform reliably and efficiently, meeting the needs and expectations of consumers.

- Q: How do steel billets contribute to the manufacturing of medical devices?

- Steel billets are an essential raw material in the manufacturing of medical devices due to their excellent strength, durability, and corrosion resistance properties. These billets serve as the starting point for various manufacturing processes such as forging, machining, and casting, which are crucial for creating intricate and precise components used in medical devices. Additionally, steel billets are often used to produce implants, surgical instruments, and other critical medical equipment, ensuring the highest level of quality and reliability in the healthcare industry.

- Q: What are the different heat treatment processes applied to steel billets?

- Steel billets can undergo various heat treatment processes to achieve specific properties and characteristics in the final product. Common processes include: 1. Annealing: Steel billets are heated to high temperatures and then slowly cooled, often in a controlled atmosphere or furnace. This relieves internal stresses, enhances machinability, and improves ductility and toughness. 2. Normalizing: Steel billets are heated above the critical range and then air-cooled. This process refines the grain structure, improves mechanical properties, and enhances machinability. 3. Quenching: Steel billets are rapidly cooled by immersing them in a quenching medium (e.g., water, oil, or polymer) after being heated to high temperatures. This creates a hardened and stronger steel with improved wear resistance, but brittleness may increase. 4. Tempering: After quenching, hardened steel billets are reheated to a specific temperature and then cooled in still air. Tempering relieves residual stresses, reduces brittleness, and improves toughness and ductility. 5. Austempering: Steel billets are quenched in a molten salt bath or another medium just above the critical range and held at that temperature until the desired transformation occurs. Austempering results in high strength, improved ductility, and reduced distortion. 6. Martempering: Similar to austempering, martempering involves a shorter holding time at the quenching temperature. This process produces a steel with high strength, toughness, and reduced distortion. 7. Case hardening: Carbon is added to the surface layer of steel billets through carburizing or nitriding. This forms a hardened case with increased wear resistance while maintaining a more ductile core. These examples illustrate some of the heat treatment processes applicable to steel billets. The specific process chosen depends on the desired properties of the final product and the type of steel being treated.

- Q: What is Alfa carbon? What is beta carbon?

- Alfa is directly connected with the functional groups of carbon atoms of carbon atoms, such as CH3CH2COOH CH2 in which methylene propionate is Alfa carbon carbon carbon atom is the beta carbon atom is directly connected with the functional groups and the connection of the carbon (around Kazakhstan), such as the CH3CH2COOH CH3 propionic acid methyl carbon is the beta carbon

Send your message to us

Prime quality prepainted galvanized steel 700mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords