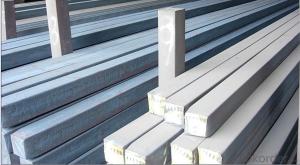

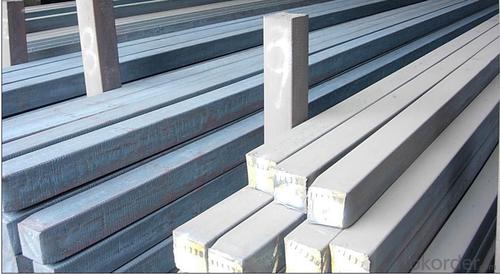

Prime Q275 125mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 125mm Square Alloy Steel Billet

Description of Prime Q275 125mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 125mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 125mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 125mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 125mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Can steel billets be used in the automotive industry?

- Yes, steel billets can be used in the automotive industry. Steel billets are semi-finished steel products that are typically used for further processing into different shapes and forms. In the automotive industry, steel billets are commonly used for the production of various automotive components such as engine parts, transmission parts, chassis components, and suspension systems. The use of steel billets in the automotive industry offers several advantages including high strength, durability, and cost-effectiveness. Additionally, steel billets can be easily formed, machined, and welded to meet specific design requirements and performance standards in the automotive sector. Therefore, steel billets play a crucial role in the manufacturing of automobiles and contribute to the overall performance, safety, and reliability of vehicles.

- Q: How are steel billets recycled?

- Steel billets undergo the process of steel billet recycling, wherein they are collected from different sources like manufacturing plants, construction sites, and scrap yards. These collected billets are then transported to a recycling facility where they go through a series of steps to become new steel products. The initial step in steel billet recycling involves sorting and cleaning. The collected billets are sorted based on their size, shape, and quality, and any impurities or foreign materials are eliminated during this stage. Once the billets are sorted and cleaned, they are prepared for the next step in the recycling process. The subsequent step is melting, in which the cleaned steel billets are melted down in a furnace at extremely high temperatures. This melting process helps in separating any remaining impurities and enables the steel to be shaped into new forms. The molten steel is then poured into molds or cast into different shapes according to the desired end product. Once the steel has cooled and solidified, it undergoes further processing to achieve the desired specifications. This may include rolling, forging, or extruding the steel billets to create various steel products like bars, rods, or sheets. These newly formed steel products are then thoroughly inspected for quality and undergo rigorous testing to ensure they meet industry standards. The final step in steel billet recycling is distribution and usage. The recycled steel products are transported to various industries such as construction, automotive, or manufacturing, where they are utilized to create a wide range of products. By recycling steel billets, we can reduce the demand for raw materials, conserve energy, and minimize environmental impact. In conclusion, the process of steel billet recycling involves sorting, cleaning, melting, shaping, and distributing. This recycling process allows us to reuse steel billets and transform them into new steel products, thereby contributing to a more sustainable and environmentally friendly approach to steel production.

- Q: Can steel billets be used in the production of appliances?

- Yes, steel billets can be used in the production of appliances. Steel billets, which are semi-finished products of steel, can be further processed and shaped into various components and parts that are used in appliances manufacturing. The high strength and durability of steel make it a suitable material for appliances, providing stability and reliability to the finished products.

- Q: How are steel billets used in the production of industrial machinery?

- Industrial machinery production relies heavily on steel billets, which serve as essential components. These billets act as the raw material that undergoes shaping and transformation processes to produce a variety of machine parts. Typically, the billets are heated and then subjected to manufacturing techniques like forging, rolling, or extrusion. Forging is a commonly employed method in the production of industrial machinery. In this process, the billets are heated to high temperatures and shaped using compressive forces applied by a forging press or hammer. This enables the steel to be molded into desired shapes and sizes, resulting in components such as gears, crankshafts, or connecting rods. Rolling is another technique that utilizes steel billets in industrial machinery production. In this method, the heated billets are passed through a series of rollers to gradually reduce their thickness and shape them into long sheets or bars. These rolled steel products can then be further processed and used in the construction of machine frames, chassis, or structural components. Extrusion, on the other hand, is a technique that also involves steel billets. In this process, the billets are heated and forced through a die to create intricate shapes with consistent cross-sections. Extruded steel parts find extensive use in the production of machine components like tubes, pipes, or profiles. Overall, steel billets play a foundational role in the manufacturing of industrial machinery. They undergo various shaping and transformation processes to produce the necessary components that contribute to the overall functionality and durability of the machinery.

- Q: How do steel billets contribute to the manufacturing of packaging materials?

- Packaging materials manufacturing heavily relies on steel billets, especially those that necessitate strength and endurance. These semi-finished steel products are typically acquired through continuous casting or hot rolling. Steel billets significantly contribute to the production of steel drums, a pivotal aspect of packaging material manufacturing. Steel drums find extensive use in industries like chemicals, petroleum, and food processing for storing and transporting diverse substances. The robustness and rigidity of steel billets make them an ideal choice for manufacturing these drums, guaranteeing the integrity of the packaging remains uncompromised even under the weight and pressure of their contents. Apart from steel drums, steel billets are also indispensable in the creation of metal cans. Metal cans enjoy broad application in packaging food, beverages, and other consumer goods. They create an excellent barrier against moisture, light, and oxygen, thereby preserving and safeguarding the packaged items. Steel billets are employed in fabricating the can bodies, lids, and bottoms, imparting requisite strength and stability to withstand the pressure during canning and transportation. Furthermore, steel billets play a vital role in manufacturing steel straps and bands for securing and bundling packages. These straps effectively secure heavy and bulky items, preventing shifting or damage during transit. The high tensile strength of steel billets ensures the straps can adequately hold packages together, providing stability and protection. Moreover, steel billets are occasionally utilized in producing corrugated steel sheets. These sheets are commonly employed in manufacturing heavy-duty packaging materials like crates and pallets. Corrugated steel sheets possess excellent strength and rigidity, making them suitable for transporting heavy items over long distances. Steel billets undergo a series of processes, such as rolling, cutting, and shaping, to transform into these sheets, ensuring the final product meets the necessary specifications. In conclusion, steel billets play a pivotal role in packaging material manufacturing. Their strength, durability, and versatility make them ideal for producing steel drums, metal cans, straps, and corrugated steel sheets. By utilizing steel billets, manufacturers can create packaging materials capable of meeting the demands of diverse industries, ensuring the safe and secure transportation of goods.

- Q: What are the different types of steel billet machining processes?

- In the industry, various steel billet machining processes are utilized. Among the most commonly employed methods are as follows: 1. Turning: By rotating the steel billet against a cutting tool, material is removed and the desired shape is achieved. This method is typically used for creating cylindrical or conical shapes. 2. Milling: Material is removed from the steel billet using a rotating multi-point cutting tool. This versatile process can be employed to fashion a range of shapes, including flat surfaces, slots, and grooves. 3. Drilling: Holes are created in the steel billet by employing a rotating drill bit. This can be done manually or through automated machines, and is often utilized to create holes for fasteners such as bolts or screws. 4. Grinding: An abrasive wheel is employed to remove material from the surface of the steel billet. This process is frequently used to achieve a smooth and precise finish or eliminate any undesired surface imperfections. 5. Sawing: The steel billet is cut using a saw blade, which can be of various types such as band saws, circular saws, or abrasive saws. Sawing is often employed to divide the billet into smaller pieces or remove excess material. 6. Broaching: Utilizing a specialized cutting tool named a broach, material is removed from the steel billet. This method is frequently applied to create internal or external features such as keyways or splines. 7. Honing: A finishing process involving the use of abrasive stones to create a smooth and precise surface on the steel billet. Honing is often employed to enhance dimensional accuracy, surface finish, and overall quality of the billet. These examples represent only a few of the diverse steel billet machining processes available. The selection of a particular process depends on the specific requirements of the project, including the desired shape, size, and surface finish of the steel billet.

- Q: What are the main factors affecting the magnetic properties of steel billets?

- The main factors affecting the magnetic properties of steel billets are the composition of the steel, the crystal structure, the presence of impurities, and the manufacturing process used.

- Q: How are steel billets used in the production of pump parts?

- Pump parts rely on steel billets as a vital element in their production. These semi-finished metal forms serve as the initial material for creating a variety of pump components. To begin with, steel billets are heated and then shaped into the desired form using techniques such as forging, casting, or extrusion. This process ensures that the billets are transformed into pump parts like impellers, casings, or shafts. Once shaped, the billets undergo further machining processes such as milling, drilling, and turning. These operations guarantee that the billets meet the precise dimensions and specifications required for pump parts. By undergoing these machining operations, the billets become functional components capable of effectively carrying out their intended tasks within the pump system. Furthermore, steel billets provide the necessary strength and durability to withstand the demanding conditions and pressures associated with pumping operations. The high tensile strength and corrosion resistance of steel make it an ideal material choice for pump components, ensuring their longevity and reliability. Additionally, steel billets can be treated or coated to enhance their performance characteristics. Heat treatment processes like annealing, quenching, or tempering can be applied to achieve specific mechanical properties such as improved hardness or increased resistance to wear and tear. Coatings such as galvanizing or electroplating can also be added to enhance the corrosion resistance of steel billets. In summary, steel billets play a crucial role in the production of pump parts. They provide a versatile and durable starting material that can be shaped, machined, and treated to meet the specific requirements of different pump systems. By utilizing steel billets, pump manufacturers can produce high-quality pump parts that ensure efficient and reliable pumping operations in various industries.

- Q: How are steel billets rolled or forged into other shapes?

- Steel billets can be transformed into various shapes through a process called rolling or forging. Rolling involves passing the heated billet through a series of rollers that apply pressure to reshape the material. This process is often used to produce long and flat shapes such as sheets, plates, and bars. During rolling, the billet is first heated to a specific temperature to make it more malleable. It is then fed into the rolling mill, where a pair of rotating rollers exerts pressure on the billet to reduce its thickness and elongate it. The rollers can be smooth or grooved, depending on the desired shape of the final product. The billet is passed through the rollers multiple times, gradually reducing its thickness and lengthening it. This process can be repeated with different sets of rollers to achieve specific dimensions and cross-sectional shapes. The final product is then cooled and cut to the desired length. Forging, on the other hand, involves applying compressive forces to the heated billet to shape it into various forms. There are two main types of forging processes: open-die forging and closed-die forging. In open-die forging, the heated billet is placed between two flat dies, and a hammer or press applies pressure to deform the material. The billet is repeatedly struck or pressed until it takes the desired shape. This process is commonly used for producing large and complex shapes such as crankshafts, connecting rods, and turbine discs. Closed-die forging, also known as impression-die forging, involves using two or more dies with cavities that mirror the desired shape of the final product. The heated billet is placed between the dies, and pressure is applied to force the material into the cavities, filling them completely. This process is often used to produce smaller and more intricate shapes like automotive parts, hand tools, and fittings. Both rolling and forging processes require the billet to be heated to a specific temperature to make it more ductile and easier to shape. The choice between rolling and forging depends on factors such as the desired shape, size, and mechanical properties of the final product.

- Q: What are the main challenges in the handling of steel billets during production?

- The main challenges in handling steel billets during production include ensuring proper transportation and storage to prevent damage, maintaining consistent temperature and humidity conditions to avoid material distortion or degradation, and implementing efficient handling techniques to minimize product loss and maximize productivity. Additionally, handling heavy and bulky billets can pose risks to worker safety, demanding proper training and equipment to mitigate potential accidents.

Send your message to us

Prime Q275 125mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords