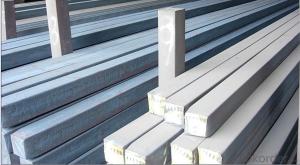

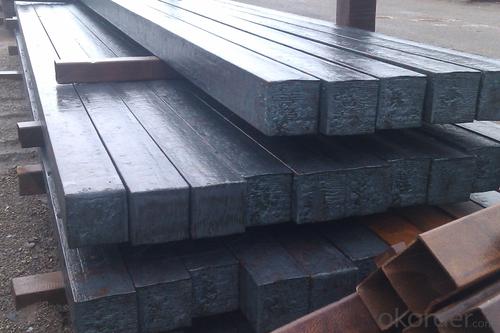

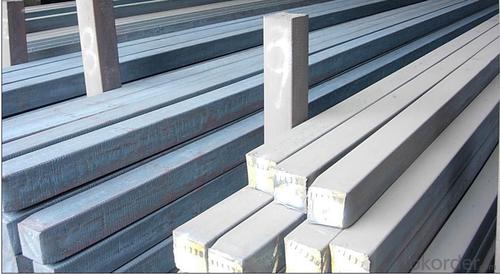

Prime Q275 115mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 115mm Square Alloy Steel Billet

Description of Prime Q275 115mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 115mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 115mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 115mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 115mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different types of steel billet surface treatments?

- There are several different types of steel billet surface treatments, including pickling, shot blasting, and painting. Pickling involves removing impurities and oxides from the surface of the billet using an acid solution. Shot blasting is a process in which small metallic or abrasive particles are blasted onto the surface of the billet to remove rust, scale, and other contaminants. Painting involves applying a protective coating or layer of paint to the surface of the billet to prevent corrosion and improve its appearance.

- Q: How is the quality of steel billets ensured during production?

- The quality of steel billets is ensured through various measures implemented during the production process. Here are some key factors that contribute to ensuring the quality of steel billets: 1. Raw Material Selection: The quality of steel billets starts with the selection of high-quality raw materials, such as iron ore, coal, and scrap metal. These materials undergo rigorous testing to ensure they meet the required specifications and standards. 2. Melting and Refining: Steel billets are produced through the process of melting and refining the raw materials. During this stage, advanced technologies and equipment are used to control the temperature and chemical composition, ensuring uniformity and consistency in the final product. 3. Continuous Casting: The molten steel is then poured into a continuous casting machine, where it solidifies into billet form. Continuous casting allows for precise control over the cooling process, resulting in billets with uniform dimensions and internal structure. 4. In-line Inspection: Modern production facilities incorporate in-line inspection systems that continuously monitor and analyze the quality of the steel billets during the production process. These systems use various techniques such as laser measurement, ultrasonic testing, and magnetic particle inspection to detect any defects or abnormalities. 5. Heat Treatment: After the initial production, steel billets may undergo heat treatment processes such as annealing or quenching to enhance their mechanical properties and eliminate any residual stresses. These treatments are carefully controlled to achieve the desired results and improve the overall quality of the billets. 6. Testing and Quality Control: Steel billets undergo comprehensive testing to ensure they meet the required standards and specifications. This includes various mechanical and chemical tests, such as tensile strength, hardness, and chemical composition analysis. Additionally, non-destructive testing methods like ultrasonic testing and X-ray inspection are employed to detect any internal defects or flaws. 7. Traceability and Documentation: Throughout the production process, comprehensive documentation is maintained to track each batch of steel billets, from the raw materials used to the final testing results. This ensures traceability and provides a record for quality control purposes. By implementing these measures and following strict quality control procedures, steel manufacturers can ensure that the steel billets produced meet the required quality standards and are suitable for further processing and use in various industries.

- Q: What are the different types of defects that can occur during casting of steel billets?

- During the casting of steel billets, several types of defects can occur, affecting the quality and integrity of the final product. Some common defects include: 1. Shrinkage: Shrinkage defects occur when the metal cools and solidifies unevenly, causing voids or shrinkage cavities in the billet. This can weaken the structure and reduce its overall strength. 2. Porosity: Porosity refers to the presence of trapped gas or air bubbles in the billet. It can occur due to improper gating or venting, inadequate control of the pouring temperature, or the presence of impurities in the molten metal. Porosity can reduce the billet's mechanical properties and make it more susceptible to failure. 3. Inclusions: Inclusions are non-metallic materials, such as oxides, sulfides, or refractory particles, that get trapped in the billet during casting. These inclusions can weaken the metal, leading to reduced ductility, increased brittleness, and decreased resistance to fatigue or corrosion. 4. Cold shuts: Cold shuts happen when two streams of molten metal fail to fuse properly during casting, resulting in a visible line or seam in the billet. Cold shuts can weaken the billet and cause it to fail under stress. 5. Hot tearing: Hot tearing occurs when the solidifying metal is restrained from contracting, leading to localized cracking or tearing. It usually happens due to high thermal stresses or inadequate feeding of the metal during solidification. Hot tearing can significantly affect the billet's structural integrity. 6. Misruns: Misruns are defects that occur when the molten metal fails to fill the entire mold cavity completely. This can happen due to inadequate pouring temperature, improper gating or venting, or insufficient fluidity of the metal. Misruns can result in incomplete, undersized, or malformed billets with reduced mechanical properties. 7. Surface defects: Surface defects include surface cracks, scabs, or surface roughness that can occur during the solidification or cooling process. These defects can lead to increased rejection rates, reduced machinability, and compromised surface finish of the billet. It is crucial to identify and minimize these defects during the casting process to ensure the production of high-quality steel billets with the desired mechanical properties and dimensional accuracy.

- Q: How are steel billets used in the manufacturing of marine equipment?

- Steel billets are an essential component in the manufacturing of marine equipment due to their unique properties and versatility. These billets, which are semi-finished steel products in a rectangular or square cross-section, play a crucial role in the production of various marine equipment such as ship hulls, propellers, offshore platforms, and marine engines. Firstly, steel billets are used in the construction of ship hulls. The high strength and durability of steel make it an ideal material for withstanding the harsh marine environment, including corrosion, extreme temperatures, and pressure. These billets are forged and shaped into plates, sections, and profiles, which are then welded together to form the hull structure. The use of steel billets ensures that the ship is robust, capable of carrying heavy loads, and resistant to the corrosive effects of seawater. Furthermore, steel billets are utilized in the manufacturing of propellers, one of the most critical components of marine equipment. Propellers are responsible for generating thrust and enabling the movement of ships and boats through the water. Steel billets are forged and machined to create the propeller blades, ensuring they possess the required strength, hardness, and hydrodynamic properties necessary for efficient propulsion. In addition, steel billets are crucial in the construction of offshore platforms used in oil and gas exploration and production. These platforms, which can be fixed or floating, require a robust and stable structure to withstand the harsh marine conditions. Steel billets are used to fabricate the columns, braces, and beams that provide the necessary strength and stability to these platforms. The high load-bearing capacity and corrosion resistance of steel make it an ideal choice for such applications. Lastly, steel billets are employed in the manufacturing of marine engines, which power various vessels. These billets are forged and machined to create the engine components such as crankshafts, connecting rods, and cylinder blocks. Steel's excellent mechanical properties, including high tensile strength, toughness, and wear resistance, ensure that the marine engines can operate reliably and efficiently under demanding conditions. In conclusion, steel billets are indispensable in the manufacturing of marine equipment. They provide the strength, durability, and corrosion resistance required to withstand the harsh marine environment. Whether it is ship hulls, propellers, offshore platforms, or marine engines, steel billets play a vital role in ensuring the safety, performance, and longevity of marine equipment.

- Q: What are the different surface defects in steel billets?

- There are several different types of surface defects that can be found in steel billets. These defects can occur during the manufacturing process or as a result of handling and transportation. Some common surface defects in steel billets include: 1. Scale: Scale is a thin layer of oxide that forms on the surface of steel billets during the heating and rolling process. It appears as a rough, flaky coating and can negatively affect the surface quality and appearance of the billet. 2. Cracks: Cracks can occur on the surface of steel billets due to various reasons such as improper cooling, excessive rolling pressure, or high levels of stress during handling. These cracks can range from minor surface cracks to more severe deep cracks, compromising the integrity and strength of the billet. 3. Lamination: Lamination defects occur when there are layers or sheets of non-metallic inclusions within the steel billet. These layers can cause weak spots in the billet, making it susceptible to failure under stress. 4. Pitting: Pitting is the formation of small, localized cavities or depressions on the surface of the steel billet. It can be caused by various factors such as corrosion, improper cleaning, or exposure to corrosive environments. 5. Slivers: Slivers are thin, elongated pieces of steel that protrude from the surface of the billet. They can be caused by improper cutting or shearing operations, which can result in sharp edges and potential safety hazards. 6. Rolled-in scale: Rolled-in scale refers to the presence of scale that has been embedded into the surface of the billet during the rolling process. This can affect the surface finish and may require additional cleaning or surface treatment. 7. Surface scratches: Surface scratches are shallow marks or abrasions on the surface of the steel billet. They can occur during handling, transportation, or as a result of contact with abrasive surfaces. While they may not significantly impact the structural properties of the billet, they can affect the aesthetics and may require further treatment or polishing. It is important to identify and address these surface defects in steel billets to ensure the quality and performance of the final product. Regular inspection, proper handling, and appropriate surface treatment techniques can help minimize these defects and improve the overall quality of the steel billets.

- Q: Can steel billets be used in the production of appliances?

- Appliances can indeed utilize steel billets for their production. These semi-finished products are typically employed for subsequent processing into diverse forms and dimensions. In the context of appliances, steel billets can serve as the primary material for fabricating elements like frames, panels, and other structural components. Steel possesses remarkable versatility and durability, providing robustness, stability, and corrosion resistance, thereby rendering it appropriate for appliances requiring sturdy construction. Moreover, steel can be effortlessly molded and shaped to fulfill the distinct design requisites of various appliances, making it the preferred choice in the manufacturing procedure.

- Q: What are the different surface treatments for improved surface cleanliness in steel billets?

- Improving surface cleanliness in steel billets can be achieved through various surface treatments. These treatments aim to eliminate impurities, oxides, and contaminants from the billet surface, resulting in a more uniform and cleaner appearance. One commonly used surface treatment is pickling, which involves immersing the steel billets in an acid solution. By dissolving and removing any oxides or scale present on the surface, pickling not only cleans the billet but also enhances the adhesion of subsequent coatings or treatments. Another option for surface treatment is shot blasting or abrasive blasting. This method entails propelling abrasive materials, like steel shot or grit, at high speeds onto the billet surface. The impact of these abrasive particles effectively eliminates contaminants, rust, or scale, thereby achieving a cleaner surface. Shot blasting is particularly suitable for preparing steel billets for further processing or coating. Chemical cleaning serves as another technique to enhance cleanliness in steel billets. This process involves employing chemical agents to dissolve and eliminate contaminants from the surface. Depending on the type and severity of the contaminants, different chemicals, such as alkaline or acid-based solutions, can be used. Chemical cleaning proves effective in removing stubborn contaminants or residues from the billet surface. Moreover, mechanical cleaning methods, namely wire brushing or grinding, can contribute to improved surface cleanliness. These approaches involve physically removing contaminants or scale from the surface using mechanical means. Wire brushing utilizes wire bristles to scrub the surface, while grinding employs abrasive materials to eliminate imperfections or contaminants. In summary, the selection of a surface treatment for enhancing cleanliness in steel billets depends on several factors, including the specific contaminants, desired cleanliness level, and intended application. It is crucial to consider the effectiveness, cost, and environmental impact of each treatment method to identify the most suitable option.

- Q: How are steel billets used in the manufacturing of pipes?

- Steel billets are an essential component in the manufacturing of pipes. These billets, which are semi-finished products made of steel, serve as the raw material for pipe production. The process begins with the selection of high-quality steel and melting it in a furnace to create a molten steel alloy. Once the steel is molten, it is poured into molds to form billets of specific sizes and shapes. The billets are then allowed to cool and solidify. This solidification process ensures that the steel attains its desired structural properties, such as strength and durability. After the steel billets have cooled, they undergo further processing to transform them into seamless or welded pipes. For the production of seamless pipes, the billets are heated and pierced to create a hollow tube-like structure. The pierced billets are then elongated and stretched to obtain the desired pipe diameter and thickness. This process, known as the hot-rolling technique, results in seamless pipes with consistent dimensions and enhanced mechanical properties. Welded pipes, on the other hand, are manufactured using different methods. One common method is the electric resistance welding (ERW) process, where the billets are first heated and then passed through a series of rollers to shape them into a cylindrical form. The edges of the billets are then fused together using an electric current, creating a continuous weld. Other welding techniques, such as submerged arc welding (SAW) and high-frequency induction welding (HFIW), can also be used to manufacture welded pipes from steel billets. In both seamless and welded pipe manufacturing, the quality of the steel billets is crucial for ensuring the integrity and performance of the final product. The selection of appropriate steel grades and the adherence to strict manufacturing standards are vital to produce pipes that can withstand high pressure, extreme temperatures, and corrosive environments. In conclusion, steel billets play a vital role in the manufacturing of pipes. They serve as the starting material from which pipes are formed, whether through the hot-rolling technique for seamless pipes or various welding methods for welded pipes. By utilizing high-quality steel billets and employing precise manufacturing processes, pipes can be produced with the necessary strength, durability, and dimensional accuracy to meet a wide range of industrial and commercial applications.

- Q: What are the different surface treatments for improved surface hardness in steel billets?

- There are several different surface treatments that can be used to improve the surface hardness of steel billets. These treatments are designed to enhance the wear resistance and durability of the steel, making it suitable for various industrial applications. One common surface treatment method is through carburizing. Carburizing involves introducing carbon into the surface of the steel billet by heating it in a carbon-rich atmosphere, such as methane or propane. This process forms a hard layer of high-carbon steel on the surface, known as a case, which significantly increases the surface hardness of the billet. Another surface treatment technique is nitriding. Nitriding is a process that involves exposing the steel billet to a nitrogen-rich atmosphere at elevated temperatures. This causes nitrogen atoms to diffuse into the surface of the steel, forming a hard nitride layer. Nitriding not only improves surface hardness but also enhances the resistance to wear and corrosion. A third surface treatment method is induction hardening. Induction hardening utilizes the principle of electromagnetic induction to heat the surface of the steel billet rapidly. Once the desired temperature is reached, the billet is quenched, resulting in a hardened surface layer. This treatment is particularly effective for localized hardening of specific areas on the steel billet. Additionally, shot peening is another surface treatment technique used to improve surface hardness. Shot peening involves bombarding the surface of the steel billet with small, high-velocity steel shots. This process induces compressive stresses in the surface layer, thereby increasing the hardness and fatigue resistance of the billet. Each of these surface treatments has its advantages and disadvantages, and the choice of treatment method depends on the specific requirements and intended use of the steel billets. By selecting an appropriate surface treatment, manufacturers can ensure that steel billets possess the necessary hardness and durability for their intended applications.

- Q: What are the different types of surface defects found in steel billets?

- Steel billets can contain various types of surface defects, which may arise from the manufacturing process or external factors. Common surface defects in steel billets include: 1. Scale: During heating and cooling, an oxide layer called scale can form on the billet's surface. This thin layer resembles rust and can impact the steel's quality and appearance. 2. Cracks: Improper cooling or excessive stress can cause cracks during manufacturing. These cracks may be longitudinal or transverse and weaken the billet's structural integrity. 3. Pits: Small depressions or cavities known as pits can develop on the billet's surface. They may result from impurities or corrosion. 4. Seam: Improperly joined sections during manufacturing can lead to a linear defect called a seam along the billet's surface. 5. Lamination: Lamination defects occur when layers or flakes detach from the billet's surface. This can be due to inadequate bonding between layers or improper rolling. 6. Inclusions: Non-metallic particles or impurities can become trapped within the steel billet during manufacturing. These inclusions can impact the steel's mechanical properties and overall quality. 7. Decarburization: Decarburization is a surface defect where the steel's carbon content is reduced, resulting in a softer and weaker surface layer. This defect may arise from improper heating or cooling processes. Detecting and addressing these surface defects in steel billets is crucial to ensure the quality and performance of the final steel products. Manufacturers employ various inspection methods and quality control measures during the manufacturing process to minimize the occurrence of these defects.

Send your message to us

Prime Q275 115mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords