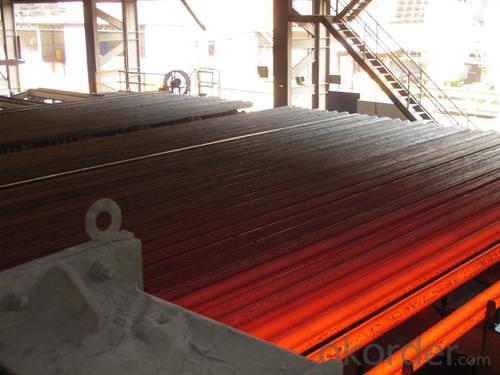

Prime Q275 100mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 100mm Square Alloy Steel Billet

Description of Prime Q275 100mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 100mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 100mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 100mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 100mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different forging methods used for steel billets?

- Steel billets can be forged using different methods, each with its own advantages and applications. Open Die Forging is a method where the steel billet is shaped between flat dies. This allows for flexibility in design and size, making it suitable for larger and more complex parts that require customization, like shafts, cylinders, and discs. Closed Die Forging, also known as impression die forging, involves shaping the steel billet within a set of dies that contain the desired shape. It is ideal for producing high-precision and complex parts with tight tolerances, such as gears, connecting rods, and crankshafts. Upset Forging is a method that involves increasing the cross-sectional area of the steel billet by compressing it between dies. This is commonly used for creating short-length parts like bolts, screws, and fasteners. Roll Forging uses cylindrical rolls to gradually shape the steel billet into the desired form. It is often used to produce long parts with a consistent cross-section, such as bars, rods, and shafts. Press Forging utilizes a hydraulic or mechanical press to shape the steel billet, providing greater control over the forging process. This method is often employed for manufacturing automotive components, aerospace parts, and tools. Isothermal Forging involves heating the steel billet and the dies to the same temperature, reducing the cooling effect during forging. This allows for greater control over the microstructure and mechanical properties of the final product, making it suitable for producing parts that require high strength and temperature resistance. Each forging method has its own benefits, allowing steel billets to be shaped into a wide range of products with varying complexity, size, and mechanical properties. The choice of forging method depends on factors such as the desired product, material properties, production volume, and cost considerations.

- Q: What are the different types of steel billet cutting processes?

- There are several different types of steel billet cutting processes used in various industries. Some of the most common types include: 1. Shearing: This process involves using a shear machine to cut the steel billet into the desired shape. Shearing is typically used for cutting straight lines and is a cost-effective method for smaller billets. 2. Sawing: Sawing is another popular method for cutting steel billets. It involves using a circular or band saw to cut through the billet. Sawing is suitable for cutting both straight and curved lines, making it more versatile than shearing. 3. Flame cutting: Flame cutting, also known as oxy-fuel cutting, uses a combination of oxygen and a fuel gas (such as acetylene) to heat the steel to its ignition temperature. A high-pressure stream of oxygen is then directed onto the heated area, causing the steel to oxidize and melt away. This process is commonly used for cutting thicker steel billets. 4. Plasma cutting: Plasma cutting involves using a plasma torch to cut through the steel billet. The torch generates a high-temperature plasma arc that melts the metal, while a high-velocity gas stream blows away the molten metal. Plasma cutting is often used for cutting through thick steel billets or for creating intricate shapes. 5. Waterjet cutting: Waterjet cutting utilizes a high-pressure jet of water mixed with an abrasive material (such as garnet) to cut through the steel billet. The abrasive particles in the waterjet help erode the steel, allowing for precise and clean cuts. Waterjet cutting is commonly used for cutting complex shapes or materials that are sensitive to heat. These are just a few of the different types of steel billet cutting processes available. The choice of method depends on factors such as the size of the billet, desired shape, precision requirements, and the budget available.

- Q: What are the different types of steel billet extrusion processes?

- There are several different types of steel billet extrusion processes used in the manufacturing industry. These processes involve shaping a solid steel billet into a desired profile or shape by applying high pressure. 1. Direct Extrusion: This is the most common type of steel billet extrusion process. In this method, the billet is placed inside a container called a "container" or "container die." The container has a small opening called a "die" through which the billet is forced using a ram or a piston. The steel billet is pushed through the die, and the resulting shape is formed. 2. Indirect Extrusion: In this process, the container die is stationary, and the billet is pushed through the die using a punch or a ram. The billet is placed inside a hollow chamber called a "container" or "container die" with a smaller diameter opening at one end. The punch is then used to apply pressure on the billet, forcing it to flow through the die and take the shape of the desired profile. 3. Impact Extrusion: This process is similar to direct extrusion, but it involves using a punch with a specially designed shape. The punch strikes the billet with a high impact force, causing it to flow and take the shape of the die. Impact extrusion is commonly used for producing small, intricate shapes with thin walls. 4. Hydrostatic Extrusion: In this process, the billet is placed inside a sealed chamber filled with a pressurized fluid, usually oil or water. The fluid pressure is applied to the billet, forcing it to flow through the die and take the desired shape. Hydrostatic extrusion is often used for producing complex shapes with high precision. 5. Cold Extrusion: This process involves extruding the steel billet at room temperature, without the need for heating. Cold extrusion is commonly used for producing small, intricate parts with high dimensional accuracy. It is a cost-effective method that allows for the production of parts with excellent surface finish. Each of these steel billet extrusion processes has its own advantages and limitations, and the choice of process depends on factors such as the desired shape, size, material properties, and production requirements.

- Q: How are the surface defects of steel billets repaired?

- The surface defects of steel billets can be repaired through various methods, depending on the type and severity of the defect. Some common surface defects include cracks, seams, laps, and scale. One method of repairing surface defects is through grinding or milling. This involves removing the surface layer of the billet using abrasive tools or machines. Grinding can effectively eliminate small defects such as scale, pits, or minor cracks. However, it may not be suitable for deep or extensive defects. For more severe defects like cracks or seams, a common repair technique is welding. The damaged areas are preheated to a suitable temperature, and then the cracks or seams are filled using welding electrodes or filler materials. This process requires skilled welders to ensure proper fusion and strength of the repaired area. In some cases, surface defects can be repaired through mechanical methods such as peening or hammering. These techniques involve using specialized tools to reshape and smooth out the affected areas. Peening can be effective for eliminating shallow cracks or surface irregularities. Ultrasonic testing is another method used to identify and repair surface defects in steel billets. It involves using high-frequency sound waves to detect any hidden cracks or flaws. Once the defects are identified, appropriate repair methods can be employed. It is important to note that the repair process for surface defects in steel billets requires careful inspection and assessment to determine the most suitable method. Quality control measures must be put in place to ensure that the repaired billets meet the required standards for strength and integrity.

- Q: What are the common uses of steel billets?

- Steel billets are semi-finished metal products that serve as a precursor to various steel products. They are typically produced through the process of continuous casting or hot rolling, resulting in a solid, rectangular shape. Due to their versatility and strength, steel billets have numerous common uses across various industries. One of the primary applications of steel billets is in the production of long steel products such as bars, rods, and wires. These billets serve as the starting material for further processing, where they are reheated and shaped into the desired form. Long steel products find extensive use in construction, infrastructure development, manufacturing, and transportation industries. Steel billets are also utilized in the production of seamless pipes and tubes. By subjecting the billets to the process of piercing and elongation, they can be transformed into seamless tubes that are widely used in oil and gas exploration, automotive manufacturing, and structural engineering. Furthermore, steel billets play a crucial role in the production of forged steel components. Forging involves shaping the heated billet through the application of pressure, resulting in high-strength and durable products. These forged components are widely used in industries such as aerospace, automotive, and power generation. In addition to these applications, steel billets are also used in the production of various other steel products like beams, channels, and profiles for construction purposes, as well as in the manufacturing of machine parts and tools. Overall, the common uses of steel billets can be summarized as the starting material for the production of long steel products, seamless pipes, forged components, and other steel products. Their versatility, strength, and malleability make steel billets an essential raw material in numerous industries.

- Q: What are the common alloys used in the production of steel billets?

- The common alloys used in the production of steel billets are primarily carbon and manganese. Carbon is added to increase the hardness and strength of the steel, while manganese is added to improve the steel's toughness and hardenability. Additionally, other alloying elements such as silicon, nickel, chromium, and vanadium may be added in smaller amounts to further enhance specific properties of the steel, such as corrosion resistance, heat resistance, or wear resistance. These alloying elements help create a wide range of steel grades with varying characteristics that can be tailored to suit different applications and industries.

- Q: What are the main factors affecting the magnetic properties of steel billets?

- The magnetic properties of steel billets are impacted by three key factors: composition, microstructure, and processing conditions. To begin, the composition of the steel billet plays a crucial role in determining its magnetic properties. The inclusion of specific alloying elements like nickel, cobalt, and manganese can enhance the magnetic characteristics of the steel. These elements align the magnetic domains within the steel, leading to increased magnetization and improved magnetic properties. Next, the microstructure of the steel billet influences its magnetic behavior. Factors such as grain size, crystal structure, and the presence of defects or impurities can all affect the magnetic properties of the material. Smaller grain sizes tend to exhibit superior magnetic properties due to better alignment of the magnetic domains. Furthermore, a single-phase crystal structure generally possesses greater magnetism compared to a multi-phase structure. Lastly, the processing conditions employed during the production of steel billets can impact their magnetic properties. Variables such as temperature, cooling rate, and mechanical deformation can all affect the microstructure and consequently, the magnetic behavior. For instance, rapid cooling can result in finer grain sizes and improved magnetic properties. Similarly, mechanical deformation can induce magnetic anisotropy, aligning the steel billet in a specific direction and enhancing its magnetic orientation. In conclusion, the magnetic properties of steel billets are primarily influenced by their composition, microstructure, and processing conditions. By effectively managing these factors, manufacturers can customize the magnetic properties of steel billets to meet the specific requirements of various applications, including electrical transformers, motors, and magnetic sensors.

- Q: What are the main factors affecting the weldability of steel billets?

- The main factors affecting the weldability of steel billets include the composition of the steel, the presence of impurities, the presence of alloying elements, the size and shape of the billets, and the heat treatment of the steel.

- Q: How are steel billets used in the manufacturing of hydraulic components?

- Steel billets are an essential raw material in the manufacturing of hydraulic components. Billets are essentially semi-finished forms of steel, typically in a rectangular or square shape, which are further processed into various hydraulic components such as cylinders, pistons, valves, and fittings. The manufacturing process begins with the selection of high-quality steel billets that meet specific mechanical properties and chemical composition requirements. These billets are then heated to a specific temperature to make them more malleable and easier to shape. Once heated, the billets are subjected to a series of mechanical processes such as forging, extrusion, or rolling to transform them into the desired shape and size. For example, in the production of hydraulic cylinders, the heated billets are typically forged or extruded to form the cylinder body. This involves applying intense pressure to the billet, causing it to deform and take on the cylindrical shape. The resulting cylinder body is then further machined to precise tolerances to accommodate internal components such as pistons, seals, and valves. Similarly, hydraulic valves and fittings are also manufactured using steel billets. The billets are machined using various machining techniques such as turning, milling, drilling, and grinding to create the intricate shapes and features required for these components. The final products are then heat-treated or surface-treated to enhance their strength, durability, and corrosion resistance. Steel billets are preferred in the manufacturing of hydraulic components due to their excellent mechanical properties, including high strength, good ductility, and weldability. These properties ensure that the components can withstand high pressures, extreme temperatures, and harsh operating conditions commonly encountered in hydraulic systems. In summary, steel billets are an integral part of the manufacturing process for hydraulic components. They are transformed through various mechanical processes to create the necessary shapes and sizes required for cylinders, pistons, valves, and fittings. The use of steel billets ensures the production of high-quality, reliable hydraulic components that can effectively perform in demanding hydraulic systems.

- Q: How do steel billets contribute to the sustainability of construction projects?

- Steel billets contribute to the sustainability of construction projects in several ways. Firstly, steel is a highly durable and long-lasting material, ensuring that structures built with steel billets have a longer lifespan and require less maintenance and repairs over time. This longevity reduces the need for frequent reconstruction, saving resources and minimizing waste. Additionally, steel is a recyclable material, meaning that steel billets can be reused or repurposed at the end of their life cycle, reducing the demand for new steel production and lowering the environmental impact. Lastly, steel's strength-to-weight ratio allows for lighter and more efficient designs, resulting in reduced material consumption and energy usage during construction. Overall, the use of steel billets in construction projects promotes sustainability by enhancing durability, facilitating recycling, and optimizing resource efficiency.

Send your message to us

Prime Q275 100mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords