Prime Q275 95mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

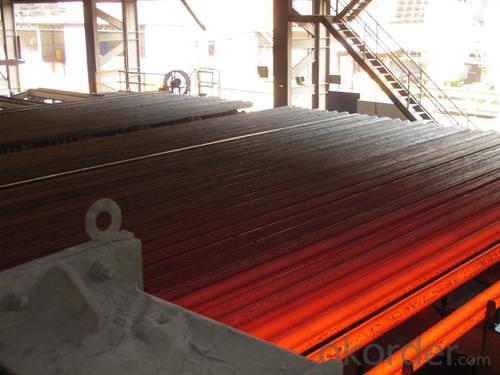

Structure of Prime Q275 95mm Square Alloy Steel Billet

Description of Prime Q275 95mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 95mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 95mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 95mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 95mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: Can steel billets be customized in terms of shape and size?

- Yes, steel billets can be customized in terms of shape and size. They can be fabricated into various shapes and sizes to meet specific requirements and applications.

- Q: What are the different types of surface finishes available for steel billets?

- Steel billets have a range of surface finishes that cater to specific needs and offer distinct qualities. Some of the most commonly used surface finishes for steel billets include: 1. Hot Rolled: This is the most basic finish achieved by heating the steel billet above its recrystallization temperature and then rolling it to the desired shape and size. Hot rolled steel billets have a rough and scaled surface, suitable for applications where aesthetics are not a primary concern. 2. Cold Rolled: This finish is obtained by subjecting the hot rolled billets to a series of cold rolling processes. Cold rolled steel billets have a smoother and refined surface, with tighter tolerances and improved dimensional accuracy. 3. Pickled and Oiled: This finish involves removing rust, scale, or mill scale from the steel billets by immersing them in an acidic solution, known as pickling. After pickling, the steel billets are oiled for temporary corrosion protection. This finish is ideal for applications where cleanliness and corrosion resistance are crucial. 4. Galvanized: Galvanizing is a process that coats the steel billets with a layer of zinc for enhanced corrosion resistance. This finish is particularly suitable for outdoor applications or high humidity environments, offering protection against rust and corrosion. 5. Electroplated: Electroplating involves depositing a thin layer of metal, such as nickel or chromium, onto the steel billets through an electrochemical reaction. This finish enhances aesthetics, corrosion resistance, and can provide specific functional properties like hardness or wear resistance. 6. Powder Coated: Powder coating is a technique where dry powder is electrostatically applied to the steel billets and then cured under heat to form a durable and protective coating. This finish offers excellent corrosion resistance, impact resistance, and a wide range of color options, making it popular in architectural and decorative applications. 7. Anodized: Anodizing, commonly used for aluminum, can also be applied to steel billets. This process creates an oxide layer on the steel's surface through electrolysis. Anodized steel billets exhibit improved corrosion resistance, increased hardness, and can be dyed in various colors for aesthetic purposes. These examples illustrate the variety of surface finishes available for steel billets. The choice of finish depends on specific requirements such as aesthetics, corrosion resistance, durability, and functional properties.

- Q: How do steel billets contribute to the manufacturing of water and wastewater treatment equipment?

- Steel billets are used in the manufacturing of water and wastewater treatment equipment as they serve as the raw material for various components such as pipes, tanks, and structural supports. These billets are melted and shaped into the required forms, ensuring the durability and strength of the equipment. Additionally, steel billets can be further processed to create corrosion-resistant coatings, ensuring the longevity and reliability of the equipment in harsh water and wastewater environments.

- Q: What are the properties of alloy steel billets?

- Alloy steel billets possess a combination of properties that make them highly desirable for various applications. These properties include high strength, excellent hardness and wear resistance, good toughness, and improved corrosion resistance compared to carbon steel. Additionally, alloy steel billets have the ability to withstand high temperatures and exhibit excellent machinability, making them ideal for use in industries such as automotive, aerospace, construction, and manufacturing.

- Q: How do steel billets contribute to the overall fire resistance of a structure?

- Steel billets do not directly contribute to the fire resistance of a structure. However, steel is a fire-resistant material and when used in the construction of a building, it can enhance the overall fire resistance by providing structural integrity and stability even at high temperatures.

- Q: How do steel billets contribute to the manufacturing of defense equipment?

- The role of steel billets in the manufacturing of defense equipment cannot be overstated. These semi-finished steel products serve as vital raw materials in various manufacturing processes. In order to meet the demands of defense equipment, materials must possess strength, durability, and the ability to withstand extreme conditions. Steel billets fulfill these requirements flawlessly. When it comes to defense manufacturing, steel billets are primarily utilized in the production of armored vehicles and tanks. The construction of these vehicles necessitates resistance against ballistic threats and the ability to protect soldiers inside. Steel billets, known for their exceptional strength and toughness, are the optimal choice for manufacturing armor plates used in these vehicles. Through the transformation of billets into thick, hardened steel plates, excellent ballistic resistance is achieved, enabling them to withstand high-velocity impacts. Furthermore, steel billets play a crucial role in the production of weaponry, including firearms and missiles. These weapons require materials capable of handling the intense pressure and heat generated during firing or launching. Steel billets, possessing high tensile strength and heat resistance, provide the necessary foundation for creating barrels, chambers, and other critical components of these weapons. In addition, steel billets contribute to the manufacturing of defense equipment by being employed in the production of various support structures and infrastructure. This encompasses military facilities, such as hangars, barracks, and storage facilities, which demand robustness and security. Steel billets are transformed into beams, columns, and other structural elements that provide strength and stability to these buildings. To summarize, steel billets are an indispensable component in defense equipment manufacturing. Their strength, durability, and capacity to withstand extreme conditions make them ideal for producing armored vehicles, weaponry, and support structures. By utilizing steel billets, defense manufacturers can ensure the production of high-quality, reliable equipment that meets the stringent requirements of the defense sector.

- Q: What are the potential applications of steel billets in the automotive sector?

- Steel billets have a wide range of potential applications in the automotive sector. One of the key uses of steel billets is in the production of automotive parts and components. These billets can be further processed and shaped into various forms such as rods, bars, and sheets to manufacture critical components like engine parts, chassis, and suspension systems. The strength and durability of steel make it an ideal material for automotive applications. Steel billets can be transformed into high-strength steel alloys, which are known for their excellent mechanical properties, including high tensile strength, hardness, and impact resistance. These properties make steel billets suitable for use in structural components, such as the frame and body of vehicles, providing stability and enhancing passenger safety. Steel billets are also used in the production of engine parts, such as crankshafts, camshafts, and connecting rods. These components require high strength and resistance to wear and fatigue, which steel billets can provide. Additionally, steel billets can be used to manufacture gears, axles, and transmission components, which require excellent mechanical properties to withstand the demanding conditions of the automotive industry. Furthermore, steel billets find application in the manufacturing of suspension systems, including control arms, stabilizer bars, and springs. These components need to withstand heavy loads, vibrations, and impacts while ensuring optimal ride comfort and handling. Steel billets' high strength and toughness make them suitable for these critical suspension components. Moreover, steel billets are also utilized in the production of safety features in automobiles. For instance, they can be used to manufacture reinforced door beams, which enhance the structural integrity of the vehicle and provide protection in the event of a collision. Additionally, steel billets can be employed in the production of seat frames and seatbelt components, ensuring passenger safety and restraint systems. Overall, the potential applications of steel billets in the automotive sector are vast and crucial. Their strength, durability, and excellent mechanical properties make them indispensable for the production of various automotive components, ranging from engine parts to structural elements and safety features.

- Q: What are the common challenges in steel billet production?

- There are several common challenges in steel billet production that manufacturers often face. One of the primary challenges is maintaining consistent quality throughout the production process. Steel billets need to meet specific standards and specifications in terms of chemical composition, mechanical properties, and surface finish. Any deviation from these requirements can lead to rejection of the billets, causing delays and additional costs. Therefore, ensuring consistent quality control throughout the production cycle is crucial. Another challenge is achieving the desired size and shape of the billets. Steel billets come in various sizes and shapes, depending on the intended use. Producing billets with accurate dimensions and shape requires precision and careful calibration of the equipment involved in the production process. Any deviation in size or shape can result in difficulties during downstream processes, such as rolling or forging, and may lead to product defects or inefficiencies. Maintaining efficient production rates is also a common challenge. Steel billet production often involves complex and time-consuming processes, such as melting, casting, and cooling. Any disruption or bottleneck in these processes can significantly impact the production rate and overall efficiency. It is crucial to optimize the production flow and identify and address any bottlenecks in order to meet demand and minimize production delays. Controlling energy consumption and minimizing waste is another challenge in steel billet production. The production of steel billets requires high energy inputs, such as electricity and fuel. Finding ways to reduce energy consumption and optimize the use of resources can help minimize production costs and environmental impact. Additionally, minimizing waste generation and implementing effective recycling or reusing strategies can further enhance the sustainability of the production process. Lastly, ensuring the safety of workers and maintaining a safe working environment is a critical challenge in steel billet production. The production process involves working with heavy machinery, high temperatures, and potentially hazardous materials. Implementing robust safety protocols, providing appropriate personal protective equipment, and conducting regular safety audits are essential to prevent accidents and ensure the well-being of the workforce. Overall, steel billet production faces challenges related to maintaining consistent quality, achieving accurate size and shape, maintaining efficient production rates, controlling energy consumption, and ensuring worker safety. Overcoming these challenges requires continuous improvement, investment in technology and equipment, and a commitment to quality control and safety measures.

- Q: What are the safety precautions when handling steel billets?

- When handling steel billets, it is important to follow several safety precautions to minimize the risk of accidents and injuries. Firstly, it is crucial to wear appropriate personal protective equipment (PPE) such as safety glasses, steel-toed boots, gloves, and a hard hat. Before handling steel billets, ensure that the work area is clear of any obstacles or debris that could cause trips or falls. Additionally, make sure that the billets are stored and stacked properly to prevent them from falling or shifting unexpectedly. When lifting or moving steel billets, be cautious of their weight and size. Use appropriate lifting equipment such as cranes, forklifts, or hoists to avoid strains or musculoskeletal injuries. Always adhere to the weight limits and load capacities of the equipment being used. Maintain a good grip on the billets to prevent them from slipping or falling. Avoid sharp edges or protruding parts that may cause cuts or puncture wounds. If necessary, use protective covers or padding to prevent contact with sharp or jagged edges. Proper communication is essential when handling steel billets. Ensure that there is clear communication between the workers involved in the process to avoid accidents or mishaps. Use hand signals or radios to communicate effectively, especially in noisy environments. Regularly inspect the steel billets for any defects or damage before handling them. Cracks, rust, or any other issues can compromise the structural integrity of the billets and increase the risk of accidents. If any defects are detected, report them to a supervisor and follow the appropriate procedures for handling or disposing of the billets. Lastly, always be aware of your surroundings and the movements of other workers when handling steel billets. Avoid standing or working in the swing radius of lifting equipment or near moving machinery to prevent being struck or crushed. By following these safety precautions, the risk of accidents and injuries while handling steel billets can be significantly reduced, creating a safer work environment.

- Q: How does the composition of steel affect the properties of steel billets?

- The composition of steel, including the ratios of different elements and the impurities present, significantly influences the properties of steel billets. For instance, the amount of carbon in steel affects its strength and hardness, with higher carbon content resulting in harder and stronger steel. Alloying elements like chromium, nickel, and molybdenum can be added to enhance specific properties such as corrosion resistance, heat resistance, or toughness. Furthermore, impurities like sulfur and phosphorus can negatively impact the ductility and weldability of steel. Hence, the composition plays a crucial role in determining the overall quality and performance of steel billets.

Send your message to us

Prime Q275 95mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords