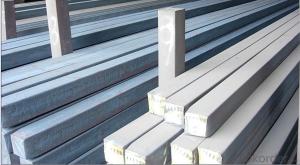

Prime Q275 135mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 135mm Square Alloy Steel Billet

Description of Prime Q275 135mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 135mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 135mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 135mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 135mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the specifications for alloy steel billets used in the aerospace industry?

- The specifications for alloy steel billets used in the aerospace industry can vary depending on the specific application and requirements. However, there are certain general specifications that are commonly followed. Firstly, the alloy steel billets used in the aerospace industry must meet stringent material standards such as the Aerospace Material Specification (AMS) and the International Organization for Standardization (ISO) standards. These standards ensure the material's mechanical properties, chemical composition, and overall quality meet the demanding requirements of the aerospace industry. In terms of mechanical properties, the alloy steel billets should possess high strength, excellent toughness, and good fatigue resistance. These properties are essential to withstand the extreme conditions and stress experienced by aircraft components during their operation. Additionally, the chemical composition of the alloy steel billets must be carefully controlled to ensure the desired alloying elements are present in the appropriate ratios. Common alloying elements used in aerospace grade steels include chromium, molybdenum, nickel, and vanadium. These elements enhance the material's strength, corrosion resistance, and heat resistance. Furthermore, the alloy steel billets must undergo specific heat treatment processes to achieve the desired microstructure and mechanical properties. Heat treatments such as quenching and tempering, solution annealing, and precipitation hardening are commonly employed to optimize the material's strength, hardness, and ductility. The size and shape of the alloy steel billets also play a crucial role in their usability. They are typically manufactured in various cross-sectional shapes, including round, square, and rectangular, to cater to different aerospace component designs. The billets should be produced with precise dimensions and tight tolerances to ensure compatibility with the manufacturing processes and facilitate the production of high-quality aerospace components. Overall, the specifications for alloy steel billets used in the aerospace industry prioritize high mechanical strength, excellent toughness, strict chemical composition control, precise dimensions, and tailored heat treatment processes. These stringent requirements ensure that the alloy steel billets meet the demanding performance and safety standards required in the aerospace industry.

- Q: How are steel billets used in the production of oil and gas machinery?

- Steel billets play a crucial role in the production of oil and gas machinery. These billets are essentially semi-finished pieces of steel that are further processed to produce various components required in the oil and gas industry. Firstly, steel billets are used to manufacture the key structural components of oil and gas machinery, such as frames, bases, and casings. These components provide the necessary strength, stability, and support to the equipment, ensuring their safe and efficient operation in harsh operating conditions. Moreover, steel billets are also used to produce critical rotating parts, including shafts, gears, and turbines. These components are subjected to high loads, intense pressure, and extreme temperatures, and therefore require exceptional strength and durability. Steel billets, known for their superior mechanical properties, are an ideal material for manufacturing such parts. Furthermore, steel billets are utilized in the production of valves, fittings, and connectors that are integral to the oil and gas machinery. These components are responsible for controlling the flow of oil or gas, regulating pressure, and ensuring a secure connection between various equipment and pipelines. Steel billets are selected for these applications due to their excellent corrosion resistance, which is critical in environments where oil and gas are present. Additionally, steel billets are employed in the fabrication of heat exchangers and pressure vessels used in the oil and gas industry. Heat exchangers play a vital role in cooling or heating fluids, while pressure vessels store and transport hazardous substances safely. Steel billets are preferred for these applications due to their high thermal conductivity, excellent weldability, and resistance to extreme pressures. In summary, steel billets are extensively used in the production of oil and gas machinery due to their exceptional mechanical properties, corrosion resistance, and thermal conductivity. These billets provide the necessary strength, durability, and reliability to the components and equipment required in the oil and gas industry, ensuring safe and efficient operations in this critical sector.

- Q: What are the different methods of steel billet surface inspection?

- There are several methods of steel billet surface inspection, including visual inspection, magnetic particle inspection, ultrasonic testing, and eddy current testing. Visual inspection involves examining the surface for any visible defects or irregularities. Magnetic particle inspection uses magnetic fields and iron particles to detect surface cracks or discontinuities. Ultrasonic testing uses high-frequency sound waves to detect internal defects or anomalies in the billet's surface. Eddy current testing involves passing an electrical current through the billet and detecting changes in the current caused by surface defects. These methods help ensure the quality and integrity of steel billets before further processing or use.

- Q: How are steel billets used in the production of valves and fittings?

- Valves and fittings heavily rely on steel billets as a vital raw material. These billets, essentially semi-finished steel products, go through various procedures to ultimately attain the desired shape and size of valves and fittings. To begin with, steel billets are heated to a specific temperature in a furnace to increase their malleability. This enables easier shaping and manipulation of the steel during subsequent forming methods. Once heated, the billets are then transferred to a rolling mill where they undergo multiple passes through rollers to gradually decrease their cross-sectional area and length. This hot rolling process refines the steel's grain structure and enhances its mechanical properties. Following hot rolling, the steel billets often undergo further processing using a technique known as extrusion. In this method, the heated billet is pushed through a die, which imparts the desired shape and dimensions onto the steel. Extrusion is commonly employed to produce cylindrical or tubular shapes, which are crucial components in valves and fittings. Once the desired shape is achieved, the extruded steel is typically subjected to heat treatment methods like quenching and tempering to enhance its strength and durability. This ensures that the final valves and fittings can withstand the demanding conditions they will encounter during their operational lifespan. Ultimately, the heat-treated steel is machined and finished to meet the specific requirements of the valves and fittings. This involves processes such as drilling, threading, and surface finishing to attain the necessary dimensions, threads, and smoothness. In conclusion, valves and fittings are produced from steel billets through a series of procedures including heating, hot rolling, extrusion, heat treatment, and machining. These processes guarantee that the resulting valves and fittings possess the necessary strength, durability, and dimensional accuracy needed for their intended applications.

- Q: How are steel billets used in the manufacturing of machinery?

- Due to their versatility and strength, steel billets play a crucial role in the production of machinery. These cylindrical metal bars, typically made from carbon or alloy steel, serve as the raw material for various machine parts and components. One common application of steel billets in machinery manufacturing involves using them to create machine frames and structures. The billets are heated and then hot-rolled or forged to achieve the desired shape. This ensures that the final product possesses the necessary strength and durability to withstand the mechanical stresses it will encounter during operation. Moreover, steel billets are utilized in the fabrication of machine components like gears, shafts, and axles. These parts require high tensile strength and resistance to wear and deformation, making steel billets the ideal material choice. Machining or forging the billets into the desired shape guarantees precise dimensions and tolerances are met. Furthermore, steel billets find application in the production of machine tools, which are vital for shaping and machining various materials. By using steel billets as the base material, machine tools can effectively handle heavy loads, provide stability, and ensure precision in the manufacturing processes. In conclusion, steel billets are essential in machinery manufacturing due to their strength, durability, and versatility. They enable the production of machine frames, components, and tools that can effectively perform their intended functions. The ability to shape, machine, and forge steel billets into various forms allows for the creation of high-quality machinery.

- Q: How do steel billets contribute to energy efficiency?

- Steel billets contribute to energy efficiency in several ways: 1. Production efficiency: Steel billets are the initial form of steel that is used in various manufacturing processes. By using steel billets as a starting material, manufacturers can achieve greater production efficiency. The uniform size and shape of billets allow for easier handling, cutting, and shaping, reducing energy consumption during the manufacturing process. 2. Resource optimization: Steel billets are typically made from recycled steel scrap. By using recycled steel as the raw material, manufacturers reduce the need for extracting and processing virgin iron ore, which is an energy-intensive process. This helps in conserving natural resources and reducing the overall energy consumption associated with steel production. 3. Heat recovery: During the manufacturing of steel billets, high temperatures are required to melt and shape the steel. However, modern steel plants are equipped with advanced technologies that allow for efficient heat recovery. The excess heat generated during the process can be captured and utilized for various purposes, such as generating steam or heating other areas of the plant. This heat recovery system helps to reduce energy wastage and increase overall energy efficiency. 4. Energy-efficient equipment: Steel billet production often involves the use of heavy machinery and equipment. Manufacturers are increasingly investing in energy-efficient technologies and equipment to reduce energy consumption. For example, using more efficient electric arc furnaces or induction heating systems can significantly reduce energy requirements compared to traditional methods. These advancements in technology contribute to the overall energy efficiency of steel billet production. Overall, steel billets play a crucial role in energy efficiency within the steel industry. From production efficiency to resource optimization and heat recovery, the use of steel billets helps in minimizing energy consumption and promoting a more sustainable steel manufacturing process.

- Q: Can steel billets be used for making kitchen utensils?

- Kitchen utensils can indeed be made using steel billets, which serve as raw materials that can be molded and crafted into various products. These steel billets must possess certain qualities like resistance to corrosion, durability, and the ability to withstand heat if they are to be used for kitchen utensils. The process of creating these utensils involves melting and casting the steel billets, which are then forged into the desired shapes and sizes. This allows for the production of knives, spoons, forks, cookware, and other utensils. To improve performance and appearance, the steel used in kitchen utensils is often treated and finished. Ultimately, steel billets play a crucial role in the manufacturing process of kitchen utensils by providing the necessary raw material needed to create durable and functional tools for cooking and food preparation.

- Q: How are steel billets used in the manufacturing of construction machinery?

- Steel billets are used in the manufacturing of construction machinery as raw material for forging, casting, and machining processes. They are formed into various components such as gears, shafts, frames, and structural parts, providing the required strength and durability for heavy-duty applications in the construction industry.

- Q: How are steel billets used in the production of forged parts?

- Steel billets are an essential component in the production of forged parts. They serve as the starting material from which the desired shape and size of the forged part is created. To begin the process, steel billets are heated to a specific temperature to make them more malleable. This temperature, known as forging temperature, allows the steel to be easily deformed without cracking or breaking. Heating the billets also improves their structural integrity and makes them more resistant to deformation during the forging process. Once the steel billets reach the desired temperature, they are placed onto a forging press or hammer. The press applies immense pressure to the billets, forcing them to take the shape of the die or mold in which they are placed. This process is known as forging and it allows for the creation of complex shapes and intricate details that cannot be achieved through other manufacturing methods. The forged parts produced from steel billets are known for their exceptional strength, durability, and resistance to wear and tear. They are widely used in various industries, including automotive, aerospace, oil and gas, and construction. Forged parts can range from small components like gears and bolts to larger items such as crankshafts, connecting rods, and turbine blades. In summary, steel billets are used in the production of forged parts by providing the raw material that is shaped and formed through the forging process. The resulting forged parts possess superior mechanical properties and are vital components in many industrial applications.

- Q: What are the different surface defects found in alloy steel billets?

- Some common surface defects found in alloy steel billets include cracks, laps, seams, scabs, and surface scale. These defects can occur during the manufacturing process or as a result of handling and transportation.

Send your message to us

Prime Q275 135mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords