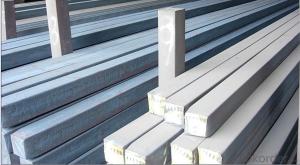

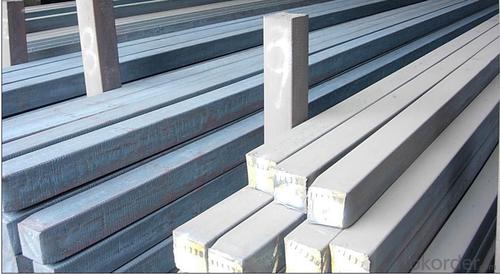

Prime Q275 110mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Prime Q275 110mm Square Alloy Steel Billet

Description of Prime Q275 110mm Square Alloy Steel Billet

1. Prepainted steel coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets.

2. The base metals for prepainted steel coil consist of cold rolled, HDGI Steel, electro-galvanized and hot-dip alu-zinc coated steel. The finish coats of prepainted steel coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the prepainted steel coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The prepainted steel coils can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Main Feature of Prime Q275 110mm Square Alloy Steel Billet

Uncoated CR steel sheet

With the features of in line with the international highest standards in demension and shape, excellent surface finish and properties, the products are mainly used in home appliance and automobile industries.

Galvanized steel sheet(include HDG and EG)

With the features of good corrosion resistance, the products are mainly used in automobile, home appliance, electronics, building and machinery manufacture industries, etc.

Precoated steel sheet

With the features of enviromental protection and good processablility, long lasting surface durability, rich in colors, the products are maily used in building, home appliance and furniture industries, etc.

Applications of Prime Q275 110mm Square Alloy Steel Billet

A. Corrugated design makes it excellent waterproof performance

B. Materials as prepainted steel sheets, galvanized steel sheets, galvalume (Al-Zn coated sheets) are available to make corrugated sheet.

C.Those material are durable, anti-corrosion in bad weather for 20-30 years based on it's Zinc(Galvanized) coating or AZ (Galvalume) coating.

D. Different shape of the sheet make it suitable for any style of buildings.

E.Easy to install, no need special tools to fix the sheet.

F.Light weight due to high strength to weight ratio of steel. Light weight means easier handling lower shipping costs, easier installation

G. Different color is availbe base on the RAL Standard make your building more beautiful.

H. We will provide the best solutions if you don't have a exact idea of the specification you want for the steel sheet based on your weather conditions, engineering structure, construction budget and so on.

Specifications of Prime Q275 110mm Square Alloy Steel Billet

Product | Billet |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.6-3.0mm |

Width | 500-1500mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z30-150g/m2 |

Technique | Raw material: Hot rolled steel coil --> Cold rolled_>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 1-25MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of Prime Q275 110mm Square Alloy Steel Billet

We have organized several common questions for our clients,may help you sincerely:

1. How Can I Visit There?

Our company is located in Tianjin City, China, near Beijing. You can fly to Tianjin Airport Directly. All our clients, from home or aboard, are warmly welcome to visit us!

2. How Can I Get Some Sample?

We are honored to offer you sample.

3. Why choose CNBM?

Our delivery time about 15-20days for standard sizes, if you have other requirements like hardness, quanity and width ,it is about 20-40days. But don't worry we also try our best for the delivery time ,because time longer and our cost is higher.

- Q: What are the different quality standards for steel billets?

- There are several quality standards for steel billets which are used to assess the overall quality and suitability of the material for various applications. Some of the prominent quality standards include: 1. ASTM A615/A615M: This standard specifies the requirements for deformed and plain carbon-steel bars for concrete reinforcement. It covers billets used in the production of reinforcing bars with specific mechanical properties and dimensional tolerances. 2. ASTM A706/A706M: This standard outlines the requirements for low-alloy steel used in the production of reinforcing bars. It specifies the chemical composition, mechanical properties, and dimensional tolerances of the billets. 3. EN 10025-2: This European standard specifies the requirements for non-alloy structural steels. It covers billets used in the production of various structural elements, such as beams, columns, and plates. The standard defines the chemical composition, mechanical properties, and technical delivery conditions of the steel billets. 4. JIS G3112: This Japanese industrial standard covers steel bars for concrete reinforcement. It outlines the chemical composition, mechanical properties, and tolerances for billets used in the production of reinforcing bars. 5. GB/T 699: This Chinese standard specifies the quality requirements for carbon structural steels. It defines the chemical composition, mechanical properties, and technical delivery conditions of steel billets used in various structural applications. These quality standards ensure that steel billets meet specific criteria for strength, durability, and dimensional accuracy. Adhering to these standards guarantees that the steel billets are of high quality and suitable for their intended use in construction, manufacturing, and reinforcement applications.

- Q: How do steel billets contribute to the manufacturing of textile machinery?

- Steel billets play a crucial role in the manufacturing of textile machinery as they are used as raw materials for creating various components and parts. These billets are transformed into different shapes and sizes through processes like casting, forging, and machining to form the necessary components of textile machinery such as gears, shafts, frames, and bearings. The high strength and durability of steel billets ensure that the textile machinery is capable of withstanding heavy loads, high speeds, and continuous operation, resulting in efficient and reliable performance in the textile industry.

- Q: How are steel billets used in the production of electrical appliances?

- Steel billets are used in the production of electrical appliances as a raw material that is shaped and formed into various components such as casings, frames, brackets, and other structural parts. These billets are melted, cast, and rolled into the desired shape and size, providing the necessary strength, stability, and durability required for electrical appliances.

- Q: How are steel billets used in the manufacturing of oil and gas industry components?

- The oil and gas industry heavily relies on steel billets, which are a necessary raw material for manufacturing various components. These semi-finished steel products have a vital role in producing pipes, valves, fittings, and other necessary equipment for oil and gas extraction, transportation, and processing. One primary application of steel billets in the oil and gas industry is their use in producing seamless and welded pipes. These pipes are extensively used for transporting oil, gas, and fluids over long distances. To form seamless pipes, the billets undergo heating and then pass through a series of rollers. For welded pipes, the billets are initially shaped into a tube and then welded along the length to create a strong and durable pipe. In addition to pipes, steel billets are also used in manufacturing valves, which play a crucial role in controlling fluid flow within pipelines and equipment. The billets are machined and shaped to create valve bodies, which are then fitted with various internal components like seats, discs, and stems. These valves are designed to withstand high pressures and temperatures, ensuring reliable and safe operation in the oil and gas industry. Moreover, steel billets are utilized in producing fittings that connect and join pipes together. Elbows, tees, couplings, and flanges are manufactured from billets by machining and shaping them into the required dimensions and configurations. These fittings are critical for creating a dependable and leak-free pipeline system for oil and gas transportation. Apart from pipes, valves, and fittings, steel billets also have applications in manufacturing other equipment used in the oil and gas industry. This includes drill bits, pumps, compressors, and various structural components for offshore platforms and refineries. The strength, durability, and corrosion resistance of steel make it an ideal material for these demanding applications, and steel billets serve as the starting point for their production. In conclusion, steel billets are of utmost importance as a raw material for manufacturing components in the oil and gas industry. Whether it is pipes, valves, fittings, or other equipment, billets undergo various processes to create the essential components needed for oil and gas extraction, transportation, and processing.

- Q: What are the specifications for tool steel billets used in the tooling industry?

- The tooling industry typically requires tool steel billets to meet specific specifications in order to achieve optimal performance and durability. These specifications encompass various aspects: 1. Alloy Composition: Tool steel billets are composed of specific alloys that provide high hardness, wear resistance, and toughness. Common elements in tool steel include carbon, chromium, vanadium, molybdenum, and tungsten. 2. Hardness: Heat treatment is applied to tool steel billets to attain the desired hardness level, often measured using Rockwell hardness (HRC). The required hardness depends on the tool's application and type. 3. Size and Shape: Tool steel billets are available in different sizes and shapes, such as rectangular or round bars, to accommodate diverse tooling requirements. The dimensions of the billets are selected based on the size and complexity of the intended tool. 4. Surface Finish: Tool steel billets must possess a smooth and clean surface finish to facilitate machining and reduce the risk of defects or flaws in the final tooling product. 5. Tolerance: Billets should be manufactured with precise dimensional tolerances to ensure consistency during the machining and tooling processes. This aids in achieving accurate tool dimensions and minimizing waste. 6. Homogeneity: Tool steel billets must exhibit uniform chemical composition and microstructure throughout to ensure consistent mechanical properties and performance in the final tooling products. 7. Heat Treatment Properties: Billets should possess favorable heat treatment properties, including the ability to be hardened and tempered. This enhances their strength, toughness, and wear resistance. 8. Machinability: Tool steel billets should have good machinability to enable efficient shaping and forming processes during tool manufacturing. This encompasses considerations for cutting forces, chip formation, and surface finish. It is important to note that the specific specifications for tool steel billets may vary depending on the application and type of tool being produced. Manufacturers and tooling experts often collaborate closely to determine the most suitable tool steel specifications for each specific tooling requirement.

- Q: How do steel billets differ from steel bars?

- Steel billets and steel bars, two intermediate steel products utilized in various industries for further processing, exhibit distinct differences. 1. Shape: Steel billets typically assume square or rectangular shapes, with cross-sectional dimensions ranging from a few inches to several feet. They are typically manufactured through continuous casting or hot rolling procedures. Conversely, steel bars adopt cylindrical shapes and maintain a uniform diameter throughout their length. They are usually produced through hot rolling or cold drawing processes. 2. Size: Steel billets tend to be larger compared to steel bars. Billets can measure from a few feet to several meters in length, while their cross-sectional dimensions can be customized based on the final product's requirements. Conversely, steel bars are typically manufactured in standardized sizes and lengths, such as 6 meters or 12 meters, and possess consistent diameters. 3. Production process: Steel billets are commonly generated through continuous casting or hot rolling methods. Continuous casting involves pouring molten steel into a mold, resulting in a solid billet. Hot rolling, on the other hand, entails passing the billet through multiple rollers to reduce its cross-sectional dimensions. In contrast, steel bars are produced through hot rolling or cold drawing processes. Hot rolling involves guiding billets through a series of rollers to achieve the desired shape and size, while cold drawing requires pulling the hot rolled bars through a die to further reduce their diameter and enhance their surface finish. 4. Applications: Steel billets primarily serve as raw materials for subsequent processing into various steel products, such as bars, rods, wires, and tubes. Additionally, they find application in the forging industry for the production of forged components. Steel bars, in contrast, enjoy a wide range of applications in construction, manufacturing, infrastructure, and automotive industries. They are commonly employed as reinforcement in concrete structures and in the production of shafts, gears, axles, and other machine parts. To summarize, steel billets and steel bars differ in terms of shape, size, production process, and applications. Billets, with their larger size and square or rectangular shape, serve as raw materials for further processing. Meanwhile, bars, with their cylindrical form and consistent diameter, find application in various industries for specific purposes.

- Q: Charcoal classification

- Hard charcoal. By hardwood such as Fagaceae Quercus, Castanopsis trees, secondary birch and etc..Broad-leaved charcoal. Charcoal made from a mixture of hard and soft hardwood.Pine charcoal. Carbon fired from pine or other needle wood. In addition to bamboo and bamboo charcoal burning with shells, stones (coconut shell, peach stone charcoal etc.) wood raw material firing. Charcoal collected from household stoves in the cell known as carbon. If the charcoal is crushed and mixed with proper adhesive, and then pressed, formed and roasted, the deposit is made. According to the burning process of silica and carbon black.

- Q: How are steel billets reheated before rolling or forging?

- Steel billets are reheated before rolling or forging by passing them through a furnace or a reheating furnace, which raises their temperature to a specific range. This process, known as billet reheating, is crucial as it improves the billets' malleability, making them easier to shape and work with during the subsequent rolling or forging operations.

- Q: How do steel billets contribute to the circular economy?

- There are several ways in which steel billets contribute to the circular economy. Firstly, they play a key role in the recycling process of steel. Steel is widely recycled around the world, and by using steel billets, scrap steel can be transformed into new products. This helps to reduce the demand for virgin iron ore and the energy-intensive processes involved in its extraction and production. Additionally, steel billets can be made from various sources, including industrial waste, automotive scrap, and construction waste. This allows for the repurposing of materials that would otherwise be disposed of in landfills, thereby reducing waste and conserving resources. By utilizing steel billets made from recycled materials, the industry can promote a more sustainable and environmentally friendly approach to steel production. Moreover, steel billets are highly versatile and can be applied in a wide range of situations. This versatility extends the lifespan of steel products and reduces the need for replacement. In the circular economy, the objective is to maximize resource utilization, and steel billets contribute to this by enabling the production of durable and long-lasting steel goods. Lastly, the circular economy places great importance on closing the loop and ensuring that materials are reused or recycled at the end of their life cycle. Steel billets facilitate this process as they are readily available for the production of new steel products. This not only reduces reliance on virgin materials but also minimizes the environmental impact associated with the extraction and processing of raw materials. In summary, steel billets play a crucial role in the circular economy by enabling steel recycling, repurposing waste materials, promoting durability, and closing the loop in the steel production process. Their use contributes to resource conservation, waste reduction, and the overall sustainability of the steel industry.

- Q: How are steel billets used in the production of railway parts?

- Steel billets are used in the production of railway parts by being heated and shaped into various forms such as rails, wheels, and axles. These billets serve as the starting material that is forged or rolled into the desired shape to meet the specific requirements of railway components, ensuring durability, strength, and reliability for safe and efficient train operation.

Send your message to us

Prime Q275 110mm Square Alloy Steel Billet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords