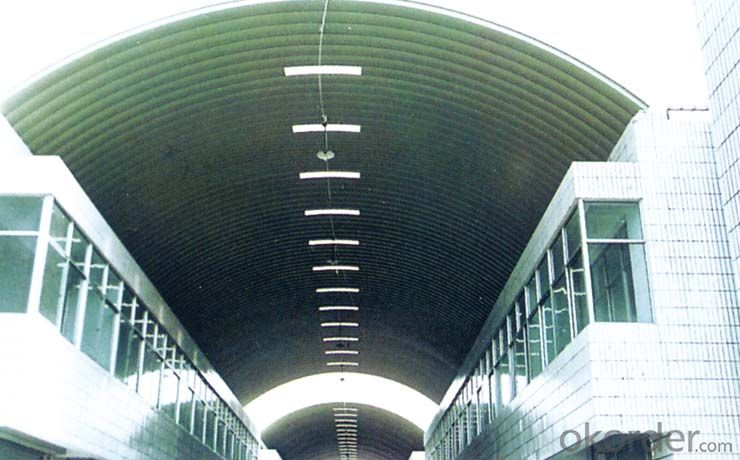

Prefabricated Light Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.Length of the welding withnot indication, full welding should be applied

2.Seam without indication is fillet weld, height is 0.75t

3.The cutting angle without indication, radius R=30

4.Cutting angle not specified should be

5.The diameter of the hole for the bolt if not specified, D=22

Steel Structure:

1.The steel structure of the connection method: welding connection

2.Steel structure design common norms are as follows: "Steel Design Code" (GB50017-2003) Cold formed steel structure technical specifications" (GB500182002) "Construction Quality Acceptance of Steel" (GB50205-2001) "Technical Specification for welded steel structure" (JGJ812002, J218 2002) "Technical Specification for Steel Structures of Tall Buildings" (JGJ99-98)

3.The characteristics of steel Light weight steel structure Higher reliability of steel work Steel anti-vibration (earthquake), impact and good Steel structure for a higher degree of industrialization Steel can be assembled quickly and accurately Large steel interior space Likely to cause sealing structure Steel corrosive Poor fire-resistant steel Recyclable steel shorter duration.

4.Commonly used steel grades and performance of steel Carbon

structural steel: Q195, Q215, Q235, Q255, Q275, etc.

High-strength low alloy structural steel Quality carbon structural steel and alloy structural steel Special purpose steel Product Feature Carport, House, Office, Shop, Toilet, Villa, Warehouse, Workshop, Plant Other Information.

Products have been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North America, the Middle East, Africa, Asia and other countries and regions, the widespread use.

- Q: What are the design considerations for steel pedestrian bridges?

- Some key design considerations for steel pedestrian bridges include structural integrity, durability, aesthetic appeal, accessibility, and safety. The bridge must be able to support the weight of pedestrians and withstand external forces such as wind and seismic activity. It should also be resistant to corrosion and have a long lifespan. Aesthetically, it should blend well with the surrounding environment and contribute to the overall visual appeal. Accessibility is crucial, requiring consideration of ramps, stairs, and elevators to ensure ease of use for people with disabilities. Lastly, safety measures such as handrails, non-slip surfaces, and proper lighting should be incorporated to ensure the well-being of pedestrians.

- Q: What are the different techniques for fireproofing steel structures?

- Some of the different techniques for fireproofing steel structures include the application of fire-resistant coatings, the use of intumescent paints, the installation of fireproofing materials such as mineral wool or concrete encasement, and the incorporation of fire-resistant insulation materials.

- Q: What does HN350*175*7*11*16 represent in steel structures?

- H section steel is a kind of economical section high efficiency profile with more optimized sectional area distribution and stronger weight ratio. It is named after the English letter "H". Because all the sections of H steel are arranged at right angles, H steel has been widely used in all directions for its advantages of high bending resistance, simple construction, cost saving and light weight.

- Q: How are steel structures designed for retail strip malls and shopping centers?

- Steel structures for retail strip malls and shopping centers are typically designed by architects and structural engineers who specialize in commercial building design. The design process involves considering various factors such as the size and layout of the building, local building codes and regulations, the desired aesthetic appeal, and the specific needs of the tenants. These professionals use computer-aided design (CAD) software to create detailed plans and structural calculations that ensure the steel structure can safely support the loads imposed by the building and its contents. Additionally, they may collaborate with other specialists, such as mechanical and electrical engineers, to integrate necessary systems into the design. Overall, the design of steel structures for retail strip malls and shopping centers focuses on creating functional, visually appealing, and safe spaces for businesses and customers.

- Q: What are the considerations when designing steel structures for data centers?

- When designing steel structures for data centers, several key considerations need to be taken into account. Firstly, the structural integrity and load-bearing capacity of the steel must be carefully evaluated to ensure it can support the weight of the data center equipment, including servers, cooling systems, and power distribution units. Additionally, factors such as seismic activity, wind loads, and extreme weather conditions in the region where the data center is located should be considered to ensure the steel structure can withstand these external forces. Furthermore, considerations for fire protection and prevention should be incorporated into the design, including fire-resistant coatings or materials. Lastly, flexibility and scalability should be considered to accommodate future growth and changes in technology, as data centers often require expansion or modification over time.

- Q: How are steel structures designed to resist soil movement and settlement?

- Steel structures are designed to resist soil movement and settlement by employing various techniques. Firstly, the foundation of the structure is designed to distribute the load evenly and deeply into the soil, reducing the risk of differential settlement. Additionally, the foundation may include measures such as piles or caissons to provide stability in areas with weak or expansive soils. Furthermore, the use of flexible connections between the steel structure and its foundation allows for some movement and settlement without compromising the overall stability. Lastly, engineers may also consider soil improvement techniques, such as ground stabilization or soil reinforcement, to enhance the soil's load-bearing capacity and mitigate potential settlement issues.

- Q: What are the design considerations for steel platforms?

- When designing steel platforms, there are several crucial factors that must be taken into consideration. These factors include: 1. Load capacity: The maximum weight that the platform needs to support is one of the primary considerations. This will determine the appropriate dimensions and structural design of the platform, ensuring it can safely accommodate the intended loads. 2. Span and support: The distance between the supports of the platform, known as the span, must be determined. It is essential to establish the appropriate spacing and number of supports to provide adequate structural stability and prevent excessive deflection. 3. Structural integrity: Steel platforms must be designed to possess sufficient strength and rigidity to withstand various loads, including live loads (people, equipment, materials) and dead loads (self-weight). The design should take into account factors such as material strength, connections, and bracing to ensure stability and prevent potential failure. 4. Safety considerations: Safety is of utmost importance when designing steel platforms. Non-slip surfaces, guardrails, handrails, and toe kicks should be incorporated to prevent accidents and falls. Compliance with local building codes and safety regulations is crucial to ensure the platform meets all necessary standards. 5. Accessibility: If the platform is intended for public use or needs to be accessible for individuals with disabilities, it is essential to consider accessibility requirements. This may involve incorporating ramps, elevators, or other features to ensure equal access for everyone. 6. Environmental factors: Depending on the location and intended use of the steel platform, environmental factors such as wind, seismic activity, and exposure to corrosive elements should be taken into account. These factors can impact the design and material selection to ensure the platform's longevity and performance. 7. Maintenance and durability: Steel platforms should be designed to be durable and require minimal maintenance. Proper finishing, coatings, and corrosion protection methods should be implemented to enhance the platform's lifespan and minimize ongoing maintenance costs. 8. Aesthetics and integration: Aesthetic considerations may be important depending on the surroundings and purpose of the steel platform. The design should consider the overall visual appeal, integration with existing structures, and any branding or architectural requirements. In summary, the design considerations for steel platforms revolve around ensuring structural integrity, safety, accessibility, durability, and meeting the specific needs of the intended application. It is recommended to consult with structural engineers and experienced professionals in the field to ensure a successful and compliant design.

- Q: How are steel structures used in the construction of retail centers and shopping complexes?

- Steel structures are commonly used in the construction of retail centers and shopping complexes due to their strength, durability, and versatility. They provide the necessary support for large open spaces, allowing for flexible floor plans and easy customization to meet the specific needs of each tenant. Steel also offers the advantage of being lightweight, which reduces construction time and costs. Additionally, steel structures can withstand heavy loads, making them ideal for supporting multiple levels, parking structures, and large atriums commonly found in retail centers and shopping complexes.

- Q: What are the design considerations for steel railway bridges?

- Some design considerations for steel railway bridges include the structural integrity and strength of the steel components to withstand the heavy loads and dynamic forces from passing trains. Additionally, the bridge must be designed to accommodate the specific track alignment, clearances, and vertical and horizontal curves of the railway. The bridge's foundation and substructure must also be carefully designed to provide stability and ensure long-term durability. Lastly, factors such as corrosion protection, maintenance access, and aesthetics are also important considerations in the design of steel railway bridges.

- Q: What are the factors to consider when designing steel structures for retail and commercial spaces?

- When it comes to designing steel structures for retail and commercial spaces, there are various factors that must be taken into account. These factors encompass: 1. Load requirements: The foremost consideration in the design of steel structures is to ensure their ability to support the expected loads. This includes the weight of the building itself, as well as the weight of its contents and any additional loads like HVAC systems or machinery. The structural engineer must calculate the necessary load-bearing capacity of the steel components to ensure they can withstand the projected loads. 2. Compliance with building codes and regulations: It is crucial to adhere to local building codes and regulations to ensure the safety and structural integrity of the steel structure. The design must meet all relevant codes, including those pertaining to fire resistance, seismic design, wind loads, and accessibility. 3. Flexibility and adaptability: Retail and commercial spaces often require the ability to adapt to changing needs and layouts. The steel structure should be designed in a way that allows for future modifications or expansions without compromising its stability or integrity. This can involve incorporating provisions for adjustable partitions, removable walls, or flexible floor plans. 4. Architectural aesthetics: The design of retail and commercial spaces is not solely focused on functionality, but also on creating an attractive environment for customers and employees. Steel structures offer a wide range of architectural possibilities, enabling unique and visually pleasing designs. Factors such as the type of steel used, finishes, and integration of other materials should be considered to achieve the desired visual impact. 5. Cost-effectiveness: Steel structures are recognized for their cost-effectiveness in terms of construction time and material efficiency. However, it is important to take the overall project budget into consideration when designing steel structures for retail and commercial spaces. The design should aim to optimize costs without compromising safety or functionality. 6. Energy efficiency: With the increasing emphasis on sustainability, energy efficiency should also be considered. Steel structures can be designed to incorporate insulation, efficient HVAC systems, and natural lighting, thereby reducing energy consumption and operating costs. 7. Maintenance and durability: Retail and commercial spaces often experience high traffic and require regular maintenance. The design should consider factors that facilitate easy maintenance and durability, such as corrosion-resistant coatings, accessible service routes, and durable finishes. In conclusion, the design of steel structures for retail and commercial spaces necessitates careful consideration of load requirements, building codes, flexibility, aesthetics, cost-effectiveness, energy efficiency, and maintenance. By taking these factors into account, architects and engineers can create spaces that are safe, functional, and visually appealing, all while meeting the specific needs of their clients.

Send your message to us

Prefabricated Light Steel Structure

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords